- inertial puller 0316-A;

- a device that simulates a shock absorber;

- key head 0539-C.

Remove torsion bars in the following order:

- remove the shock absorber when the car is on wheels;

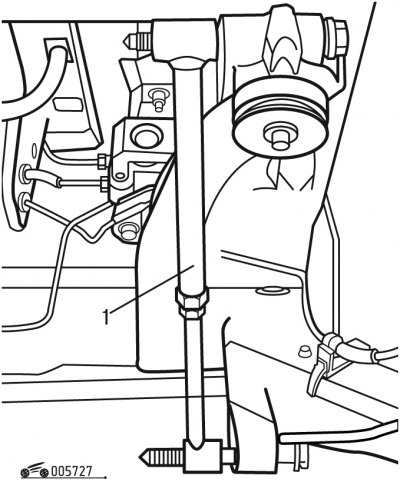

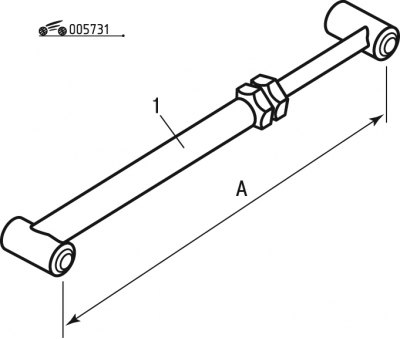

Pic. 7.27. Installing a device that simulates a shock absorber: 1 - fixture

- replace the shock absorber with tool 1 (pic. 7.27), imitating a shock absorber, and secure it with nuts;

- raise the rear of the car and place it on supports;

- remove the rear wheels;

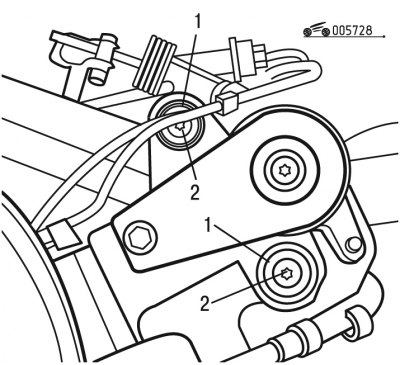

Pic. 7.28. Loosen torsion bar bolts: 1 - thrust washers; 2 - bolts

- unscrew bolts 2 (pic. 7.28) and remove thrust washers 1;

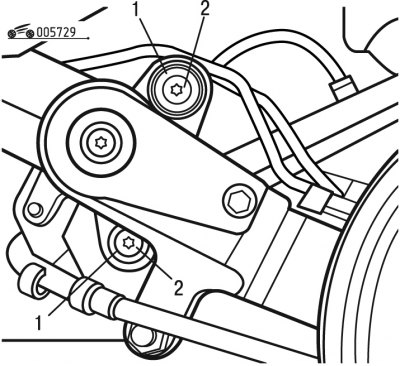

Pic. 7.29. Loosen torsion bar bolts: 1 - thrust washers; 2 - bolts

- unscrew bolts 2 (pic. 7.29) and remove thrust washers 1;

- mark with two blows with a chisel the position of the lever relative to the torsion bar;

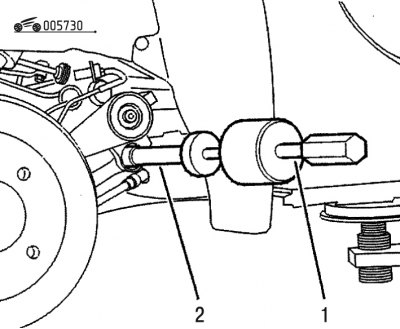

Pic. 7.30. Installation of the inertial puller: 1 - inertial puller; 2 - fixture

- install fixture 2 (pic. 7.30) at the end of the torsion bar;

- install the inertial puller 1 on the fixture;

- click on the torsion bar to rip it off;

- to remove the torsion bar, pull it;

- hold the lever to prevent it from returning back to the torsion bar;

- remove tool 2 and inertial puller 1;

Attention! Before removing the dummy shock absorber, lock the lever to hold it in its original position.

Pic. 7.31. A device that simulates a shock absorber: 1 - fixture; A - installation size

- remove the dummy shock absorber and note dimension A (pic. 7.31).

Install the torsion bars in the following order:

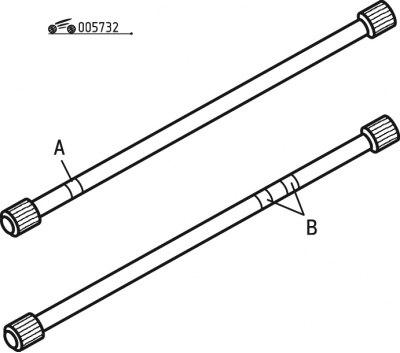

Pic. 7.32. Marks on torsion bars: A - one label; B - two marks

1) adjust size A (see fig. 7.31) fixtures: by the amount determined for the correction of the reference height; by the value specified in the characteristics when replacing the lever; by the value obtained during dismantling;

Attention! Do not mix up the levers when installing. The right lever is connected to the torsion bar, which has a round mark A (pic. 7.32) paint. The left lever is connected to the torsion bar, which has two round marks B, applied with paint.

2) clean the splines of the torsion bars and the inner splines of the levers;

3) lubricate the splines of the levers with ESSO NORVA 275 grease;

4) insert the torsion bar across the lever mount:

- in case of correction of the reference height, move the marks made during dismantling by the required number of splines;

- in case of installing a new torsion bar, turning the torsion bar by one slot, find the position in which it freely enters by 8-10 mm;

- in other cases, align the marks made during dismantling;

Note. The torsion bar is not inserted for the entire length of its splines: its ends are not located on the same axis, since the ends of the torsion bar have a pair of splines. There are two diametrically opposed positions in which the torsion bar is freely set without changing the reference height.

5) complete the installation to the stop using tool 2 (see fig. 7.30) and inertial puller 1;

6) remove the fixture and puller;

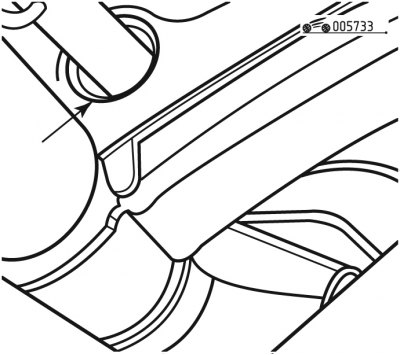

Pic. 7.33. Filling the socket with grease

7) fill the nest (pic. 7.33) grease ESSO NORVA 275;

8) apply grease to the ends of the torsion bar splines;

9) install thrust washers 1 (see fig. 7.28) and tighten bolts 2 to 20 Nm;

10) install thrust washers 1 (see fig. 7.29) and tighten bolts 2 to 20 Nm.