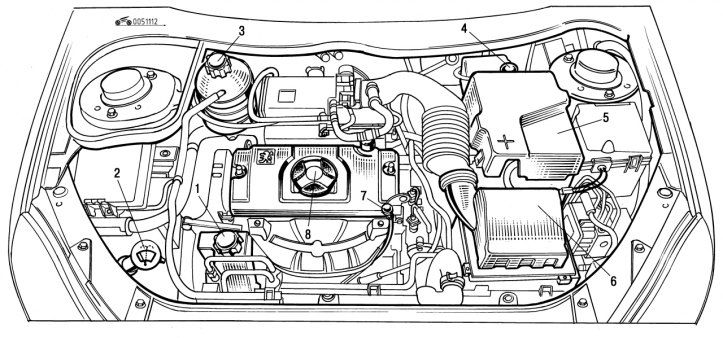

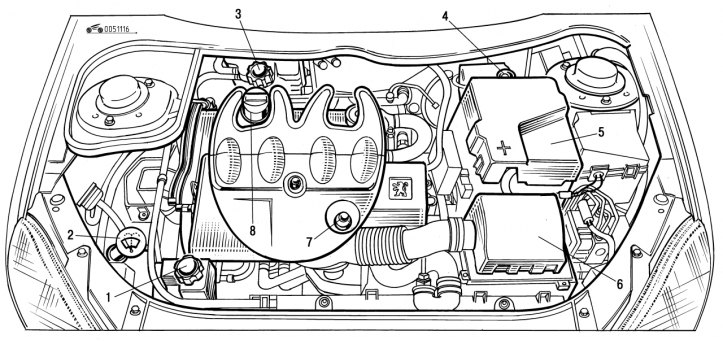

Pic. 1.112. Engine compartment (petrol engine 1.1 and 1.4 l): 1 - hydraulic booster reservoir; 2 - windshield and headlight washer reservoir; 3 - the neck of the expansion tank of the cooling system; 4 - the neck of the brake fluid reservoir; 5 - battery; 6 - air filter; 7 - oil dipstick; 8 - oil filler neck

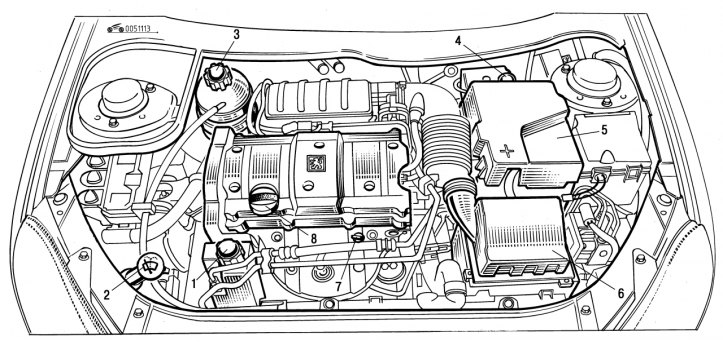

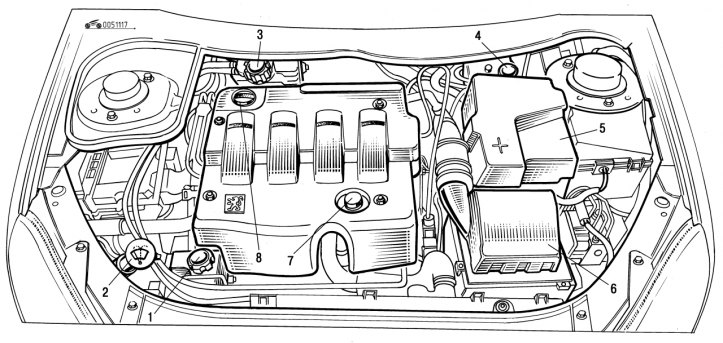

Pic. 1.113. Engine compartment (gasoline engine 1.6 l 16V): 1 - hydraulic booster reservoir; 2 - windshield and headlight washer reservoir; 3 - the neck of the expansion tank of the cooling system; 4 - the neck of the brake fluid reservoir; 5 - battery; 6 - air filter; 7 - oil dipstick; 8 - oil filler neck

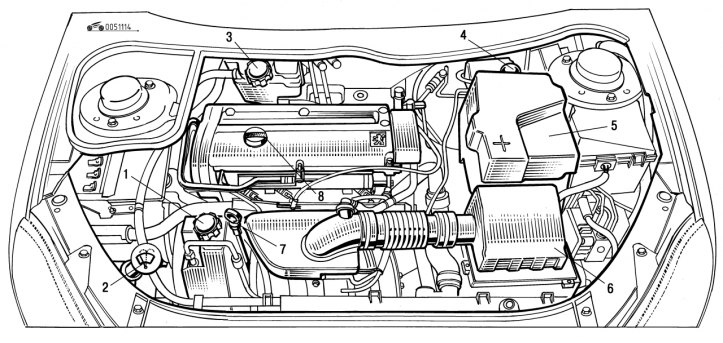

Pic. 1.114. Engine compartment (petrol engine 2.0 l 16V): 1 - hydraulic booster reservoir; 2 - windshield and headlight washer reservoir; 3 - the neck of the expansion tank of the cooling system; 4 - the neck of the brake fluid reservoir; 5 - battery; 6 - air filter; 7 - oil dipstick; 8 - oil filler neck

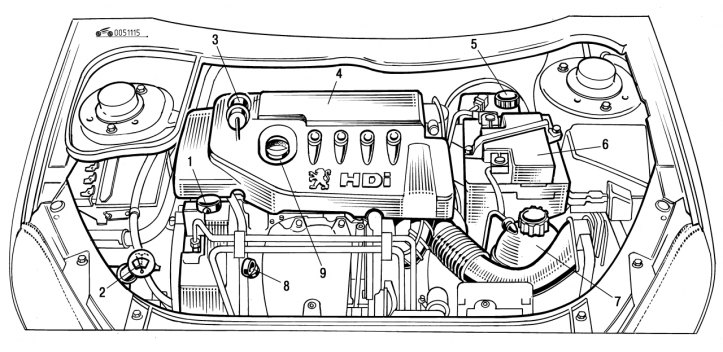

Pic. 1.115. Engine compartment (diesel engine 1.4 l HDI): 1 - hydraulic booster reservoir; 2 - windshield and headlight washer reservoir; 3 - fuel priming pump; 4 - air filter; 5 - the neck of the brake fluid reservoir; 6 - battery; 7 - expansion tank of the cooling system; 8 - oil dipstick; 9 - oil filler neck

Pic. 1.116. Engine compartment (diesel engine 1.9 l): 1 - hydraulic booster reservoir; 2 - windshield and headlight washer reservoir; 3 - the neck of the expansion tank of the cooling system; 4 - the neck of the brake fluid reservoir; 5 - battery; 6 - air filter; 7 - oil dipstick; 8 - oil filler neck

Pic. 1.117. Engine compartment (diesel engine 2.0 l, HDI): 1 - hydraulic booster reservoir; 2 - windshield and headlight washer reservoir; 3 - the neck of the expansion tank of the cooling system; 4 - the neck of the brake fluid reservoir; 5 - battery; 6 - air filter; 7 - oil dipstick; 8 - oil filler neck

This section is based on the maintenance requirements of the vehicle manufacturer and is intended to help the owner of the vehicle properly service and maintain it in good condition. When referring to one or another mechanism or unit for maintenance work, it is necessary to familiarize yourself with the sections on its design and the rules for removing and installing on a vehicle set out in this manual. This will improve the quality of work performed and save time for maintenance. The units located in the engine compartment are shown in fig. 1.112, 1.113, 1.114, 1.115, 1.116, 1.117. All types of work carried out must be coordinated with the indications of the upcoming maintenance indicators and the schedule for the frequency of maintenance. Particular attention is paid to the operating conditions of the car: road conditions, driving style, climatic conditions.

Any kind of work must begin with a car wash, preparation of the workplace, documentation (instructions), definitions of consumables and tools. The list below includes the minimum list of tools required to perform maintenance and minor vehicle repairs:

- combination wrench set (1/4 - 1 inch; 6-19 mm);

- wrench;

- candle key;

- a device for adjusting the candle gap;

- a set of measuring probes;

- a special key for pumping the brakes;

- screwdrivers («–» 8x150; «+» 2x6x150);

- combined pliers;

- hacksaw for metal with a set of blades;

- tire pressure gauge;

- grease gun;

- wrench tool for removing the oil filter;

- fine-grained sandpaper;

- wire brush;

- support stands for the car;

- oil container;

- container for antifreeze;

- filling funnel.

Work must be done in a workshop, garage or under a canopy (awning) with an equipped work table - a workbench with a bench vise opening up to 150 mm and soft pads for sponges.

Attention! When carrying out operations on the body, cover the paintwork with soft covers, covers or overlays on the wings.

If you have technical problems when disassembling a particular unit, contact the nearest Peugeot service station.