- load stabilizer type NAUDER;

- mandrels for installing oil seals at the outlet of the bridge - 0317-T / 0317-U;

- flywheel stopper - 0188-F;

- ball joint detent remover - 0317-AC;

- pulley puller - 0188-P;

- plug set - 0188-T;

- mandrel for removing the gearbox suspension axle - 0317-AB.

Removing

Removing the power unit with the DW10 TD engine is carried out in the following order:

Note. The power unit is removed upwards.

- disconnect the wire from the negative terminal of the battery;

- install the retaining rods on the front suspension springs;

- remove the mud-reflecting screens under the power unit;

- drain the liquid from the cooling system;

- drain the oil from the gearbox and engine;

- remove the front wheels by placing the car on supports;

- remove the mudguards;

- remove the CV joints on both sides;

- remove the accessory drive belt;

- disconnect the front pipe from the exhaust manifold;

Attention! Be careful when removing the exhaust pipe to avoid damaging the flexible link (bellows), which cannot withstand the torsional, tensile or bending loads that may occur when dismantling one of the suspension elements of the power unit.

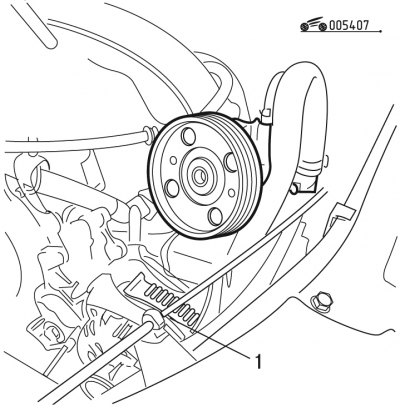

- remove the eccentric roller of the accessory drive belt;

- without disconnecting the pipelines, take aside and fix the air conditioning compressor;

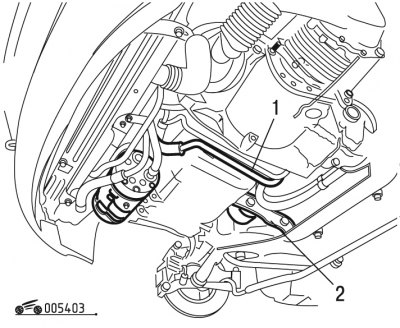

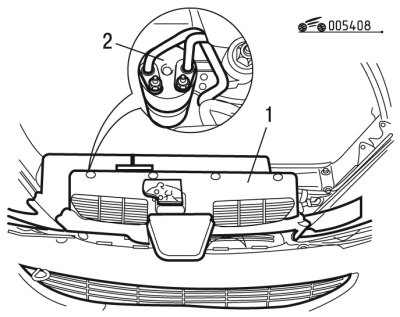

Pic. 4.3. Removing the power steering hose: 1 - hydraulic booster hose; 2 - reactive engine mount bracket

- release hose 1 (pic. 4.3) power steering;

- remove the clutch housing protection;

- fix the flywheel with a stopper;

- remove the accessory drive pulley using the tool;

- remove the jet bracket 2 engine mounts;

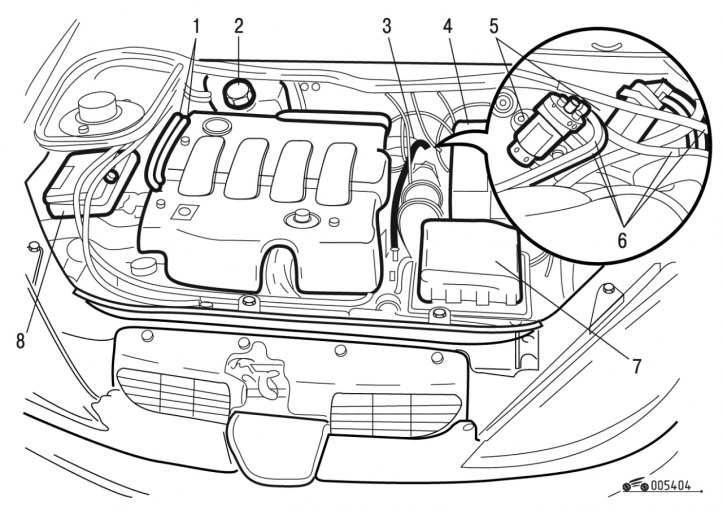

Pic. 4.4. Removing the battery and expansion tank: 1 - fitting of fuel supply pipes; 2 - expansion tank; 3 - vacuum brake booster hose; 4 - battery stand; 5 - electromagnetic valves; 6 - tubes; 7 - node; 8 - electronic block

- remove the decorative cover 8 (pic. 4.4);

- take aside node 7;

- disconnect and move aside the wiring harnesses and cables going to node 7;

- remove the battery;

- disconnect and move aside the wiring harnesses adjacent to the battery compartment;

- remove the stand 4 battery;

- remove the assembly support 7;

- remove the expansion tank 2 of the cooling system;

- remove the radiator of the cooling system;

- protect the capacitor with a piece of hard cardboard;

- mark the location of the tubes 6 on the solenoid valves 5;

- remove the solenoid valve support;

- take aside the hose of the vacuum brake booster;

- take aside the electronic unit 8 with the bracket;

- take aside the fitting 1 of the fuel supply pipes;

- close the holes with plugs;

- move the wiring harness;

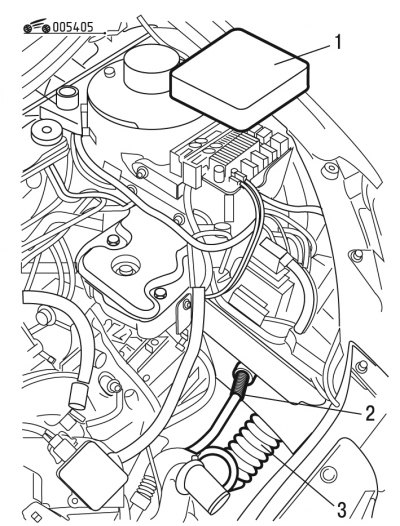

Pic. 4.5. Removing the fuse box cover: 1 - cover; 2 - wiring harness; 3 - air ducts

- remove cover 1 (pic. 4.5) fuse block;

- remove air duct 3;

- disconnect and remove the wiring harnesses of the electrical fuse box;

- disconnect and move aside the clutch actuator;

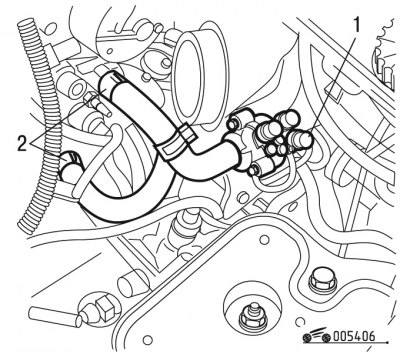

Pic. 4.6. Complete heater: 1 - heater; 2 - heat exchanger pipes

- take aside the nozzles 2 (pic. 4.6) heat exchanger;

- disconnect the wire «masses» from the spar;

- take aside the heater 1 as an assembly;

- disconnect by means of adaptation of draft of management of a transmission;

Attention! Remove the stopper with a pushing motion, without forming a lever, so as not to deform the rods.

- without disconnecting the pipelines, take aside and fix the power steering pump;

Pic. 4.7. Removing the generator: 1 - generator

- remove alternator 1 (pic. 4.7);

Pic. 4.8. Air conditioning tank: 1 - node; 2 - tank

- remove node 1 (pic. 4.8);

- release the air conditioning pipes from the clamps (front right side member);

- move the tank on the outlet tube without disconnecting the tubes;

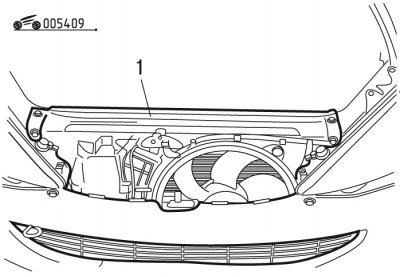

Pic. 4.9. Removing the assembly at the front of the vehicle: 1 - knot

- remove node 1 (pic. 4.9);

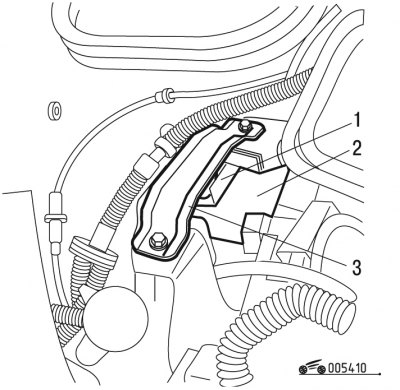

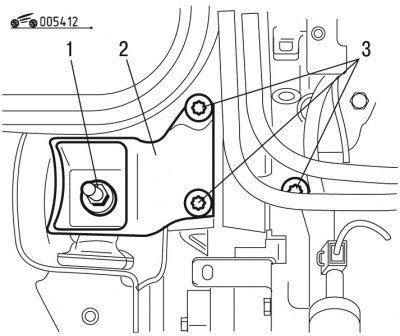

Pic. 4.10. Removing the right engine mount bracket: 1 - emphasis; 2 - right bracket; 3 - jumper

- remove jumper 3 (pic. 4.10);

- remove stop 1;

- remove the right bracket 2 engine mounts;

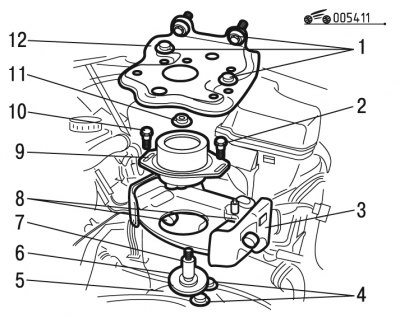

Pic. 4.11. Removing the power unit: 1, 2, 4, 8, 10 - bolts; 3, 5 - calipers; 6 - axis; 7 - spacer; 9 - pillow support; 11 - nuts; 12 - battery support

- unscrew bolts 1 (pic. 4.11) fastening of a support of the accumulator battery;

- remove the battery support 12;

- unscrew the nuts 11 of the axis of the gearbox support and remove them with washers;

- unscrew the bolts 10 pillows;

- remove the elastic cushion 9 of the gearbox support;

- unscrew bolts 8;

- remove support 3;

- remove spacer 7;

- remove axle 6 using a tool;

- unscrew bolts 4;

- remove support 5;

- lift the power unit up.

Installation

Install the power unit with the DW10 TD engine in the following order:

- replace the self-locking nuts and clamps of the exhaust system;

- using mandrels, replace the oil seals at the outlet of the gearbox, after filling the space between their edges with grease;

- reinstall the power unit;

Pic. 4.12. Engine Mount Bracket Installation: 1, 3 - bolts; 2 - bracket

- install the right bracket 2 (pic. 4.12) engine mounts;

- tighten bolts 1 and 3 to 45 Nm;

- set stop 1 (see fig. 4.10) and tighten the mounting bolts to a torque of 32 Nm;

- install jumper 3, tightening the mounting bolts to a torque of 21.5 Nm;

- install caliper 5 (see fig. 4.11), by tightening the fastening bolts 4 with a torque of 6 Nm;

- install axle 6 and spacer 7, fixing them with bolts with a tightening torque of 5 Nm;

- install support 3 axles of the gearbox, securing with bolts 8 tightening torque 19 Nm;

- install an elastic cushion 9 of the gearbox support;

- screw on the axle nut of the gearbox support, having previously installed the washer;

- tighten bolts 2 pillows (without tightening);

Attention! Center the power unit before proceeding to tighten the elastic cushion mounting bolts.

- finally tighten bolts 10 to 30 Nm;

- finally tighten nuts 11 to 65 Nm;

- install battery support 12;

- tighten the fastening bolts 1 to 19 Nm;

- install the generator;

- first tighten the crankshaft pulley bolts to 41 Nm, and then the oil filter bolts to 39 Nm;

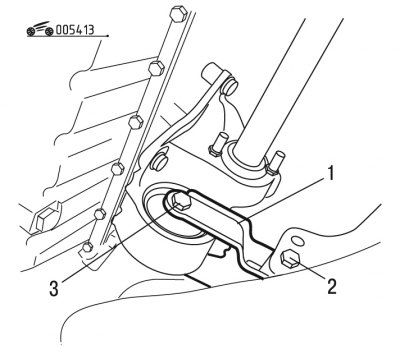

Pic. 4.13. Installation of the reaction arm of the engine mount: 1 - lever; 2, 3 - bolts

- install reaction arm 1 (pic. 4.13) engine mounts;

- tighten bolts 3 to 50 Nm;

- tighten bolts 2 to 35 Nm;

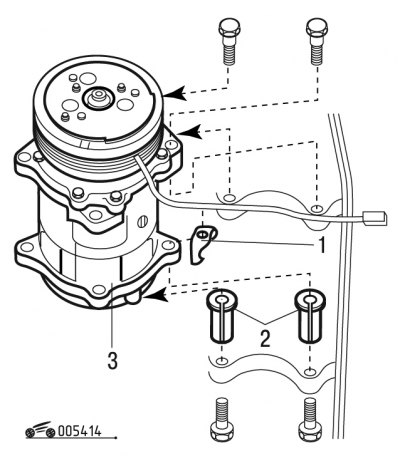

Pic. 4.14. Air conditioning compressor installation: 1 - lock nut; 2 - spacers; 3 - compressor

- make sure that two spacers 2 are in place (pic. 4.14);

Attention! The lock nut 1 secures the rear top of the compressor.

- install compressor 3 following the installation sequence of the above parts;

- connect the connector;

- install front wheel drives on both sides;

- tighten the wheel hub nuts to 325 Nm;

- install the accessory drive pulley;

- run the tap M16350 in the crankshaft internal thread under the pulley mounting bolt;

- clean the thread of the bolt with a metal brush, tighten it with a torque of 40 Nm and then tighten it to an angle of 50°using a tool like FACOM D360;

- install the pump following the parts installation sequence;

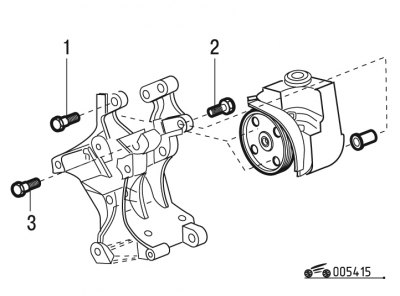

Pic. 4.15. Pump installation: 1, 2, 3 - bolts

- tighten bolt 1 (pic. 4.15) torque 25 Nm;

- tighten bolt 3 to 25 Nm;

- tighten bolt 2 to 22 Nm.

Continue installing the power unit in the reverse order of removal.

After installing the power unit, pour oil into the gearbox, and, if necessary, into the engine, after which:

- tighten the wheel bolts to 85 Nm;

- fill the engine cooling system and remove air from it;

- carry out programming of electronic devices of the car.