- traverse - 0102-D

- flywheel stopper - 0188-F;

- hanging hooks;

- fork for removing the gearbox rods - 0102-G1 / -G2;

- mandrel for installing oil seals - 0317-T / -U.

Removing

Removing the power unit with the DW8 engine is carried out in the following order:

Note. The power unit is removed upwards.

- Establish a cover of a cowl in vertical position by means of adaptation;

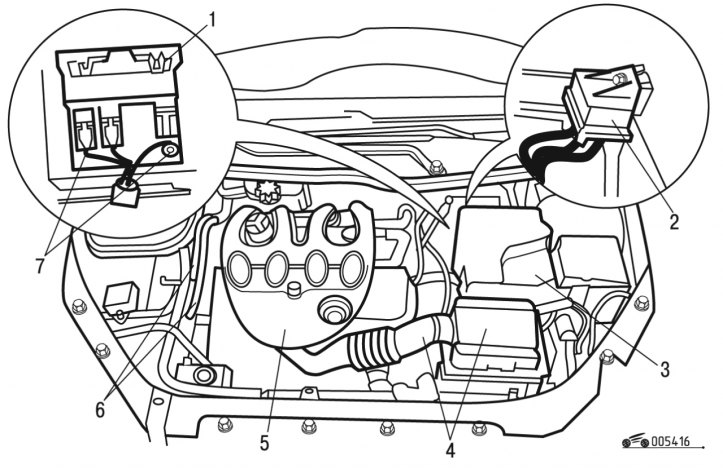

Pic. 4.16. Removing the battery: 1 - relay block; 2 - preheating block; 3 - battery; 4 - air cleaner unit; 5 - decorative cover; 6 - fitting; 7 - bolts

- remove the decorative cover 5 (pic. 4.16);

- remove block 4 of the air cleaner with air ducts;

- remove the storage battery 3 from the pallet;

- remove block 2 preheating;

- unscrew two bolts 7;

- remove block 1 relay;

- remove the air filter housing;

- remove the battery tray support;

- disconnect and move aside the fitting 6 fuel supply pipes;

- remove the electronic control unit;

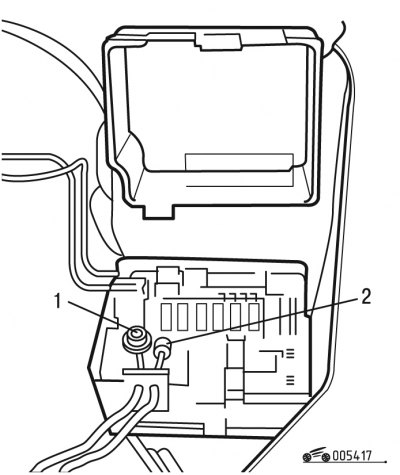

Pic. 4.17. Disconnecting wires: 1, 2 - wires

- disconnect wires 1 and 2 (pic. 4.17);

Pic. 4.18. Disconnecting tubes: 1, 2, 3, 4 - tubes

- disconnect tubes 1, 2, 3 (pic. 4.18);

- remove the front wheels;

- drain the oil from the gearbox;

- drain the coolant from the cooling system;

- remove the mudguards;

- remove the protective screen under the engine;

- remove the front wheel drives on both sides of the car;

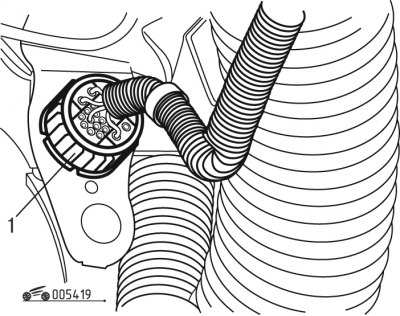

Pic. 4.19. Disconnecting the connector: 1 - pin connector

- disconnect pin 1 (pic. 4.19) on the inner panel of the left front fender;

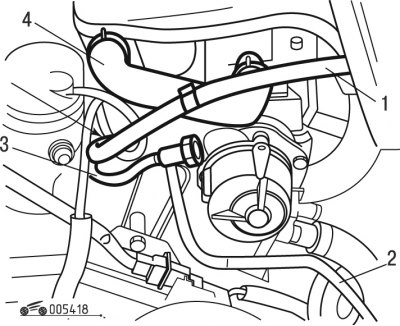

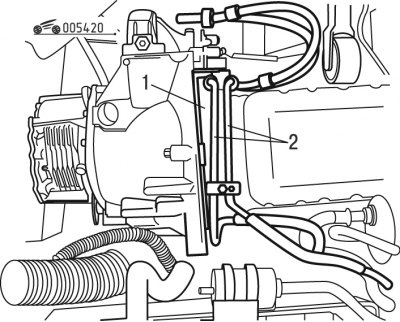

Pic. 4.20. Power steering pipes: 1 - tubes; 2 - protection board

- release and move aside tube 1 (pic. 4.20) power steering, passing in the engine area;

- remove the protective board 2;

- Disconnect the exhaust pipe from the exhaust manifold side;

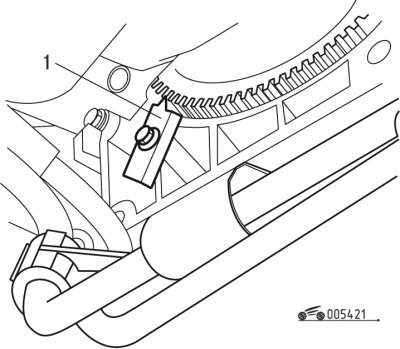

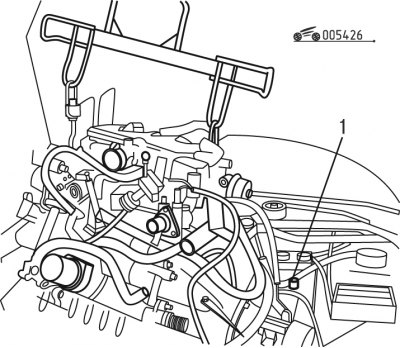

Pic. 4.21. Installing the flywheel retainer: 1 - retainer

- install latch 1 (pic. 4.21);

Pic. 4.22. Removing the jet engine mount bracket: 1 - bracket

- remove jet bracket 1 (pic. 4.22) engine mounts;

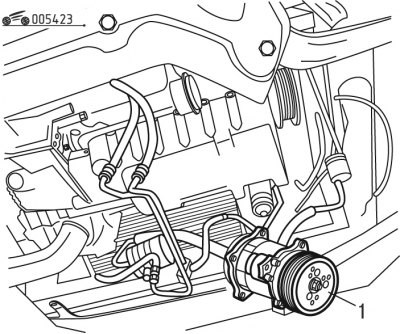

Pic. 4.23. Removing the air conditioning compressor: 1 - compressor

- without opening the refrigerant circuit of the air conditioning system, move compressor 1 aside (pic. 4.23);

Attention! Never kink the refrigerant circuit pipes of the air conditioning system.

- remove the front panel;

- move the power steering pump without opening the system circuit;

- disconnect and move aside the heat exchanger pipes at the level of the shield;

- disconnect and move aside the hose of the vacuum brake booster;

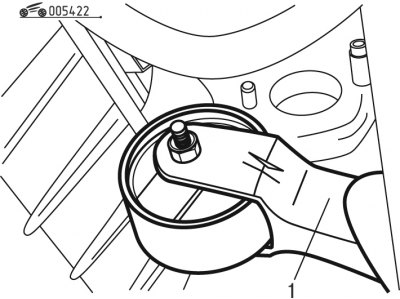

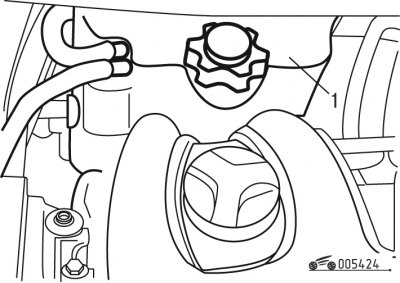

Pic. 4.24. Tank removal: 1 - tank

- move tank 1 (pic. 4.24) along with his pipes;

- move aside the flexible cable of the clutch drive or the clutch slave cylinder;

- disconnect the gearbox control rods using the tool;

- cover the tubes of the core of the condenser of the air conditioning system with a sheet of strong cardboard;

- remove the accessory drive belt;

- remove the generator;

- remove the crankshaft pulley;

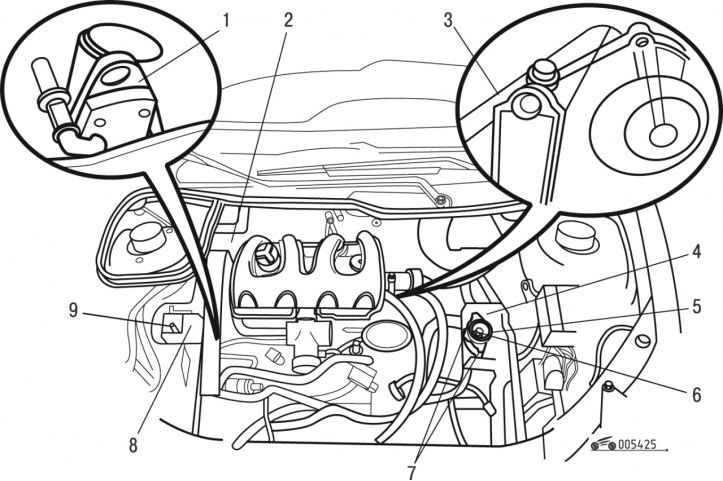

Pic. 4.25. Removal of parts and assemblies before dismantling the power unit: 1, 3 - lifting brackets; 2, 5, 7 - bolts; 4 - gasket; 6, 9 - nuts; 8 - right bracket

- bring the lifting beam with hooks, hook on the lifting brackets 1 and 3 (pic. 4.25), and then tighten the cables;

- unscrew three bolts 2;

- unscrew nut 9;

- remove the right bracket 8 of the engine mount;

- unscrew nut 6;

- unscrew two bolts 7;

- remove the elastic pad 4;

- unscrew the two bolts 5 fastening the support;

- remove the caliper;

- disconnect and set aside the wiring harnesses, pipelines related to the gearbox or engine;

Pic. 4.26. Bushing on the engine: 1 - sleeve

- remove the power unit upwards, keeping the sleeve 1 (pic. 4.26).

Installation

Install the power unit with the DW8 engine in the reverse order of removal, while observing the following:

- systematically replace self-locking nuts and seals at the outlet of the gearbox using mandrels;

Attention! Pack the space between the lips with grease before installing the seals.

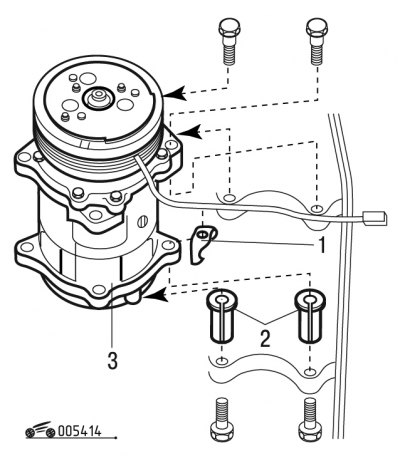

Pic. 4.14. Air conditioning compressor installation: 1 - lock nut; 2 - spacers; 3 - compressor

- install the compressor following the installation sequence of the above parts;

Attention! Lock nut 1 (see fig. 4.14) fixes the rear upper part of the compressor.

- first tighten the crankshaft pulley bolts to 42 Nm, and then the oil filter bolts to 39 Nm;

- carefully observe the laying paths and attachment points of wire bundles and wiring harnesses;

- bring the oil level in the gearbox to normal;

- fill the engine cooling system and remove air from it;

- carry out programming of all electronic devices.