Engine DW10TD

When removing and installing a toothed belt at Peugeot service centers, use the following special tool:

- belt tension measuring device - SEEM C.TRONIC (type 105.5M);

- crankshaft retainer - 0188-Y;

- camshaft fixing tool - 0188-M;

- belt support - 0188-K;

- flywheel stopper - 0188-F;

- key for turning the crankshaft - 0117-EZ;

- traverse - 0102-D;

- chain for lifting and hanging - 0102-M;

- lever stop for belt tension - 0188-J2;

- pulley puller - 0188-P;

- plug set - 0188-T.

Remove the toothed belt in the following order:

Attention! Remove downpipe to avoid damage to flex link (bellows), which cannot withstand the torsional, tensile or bending loads that may occur when dismantling one of the suspension elements of the power unit.

- remove the front right wheel;

- remove the front right mudguard;

- remove the accessory drive belt;

- remove the supply from the turbocharger;

- remove the clutch housing protection;

- fix the flywheel with a stopper;

- unscrew the bolt securing the auxiliary drive pulley;

- screw back the bolt without the washer;

- remove the accessory drive pulley using the tool;

- remove the lower reactive suspension arm;

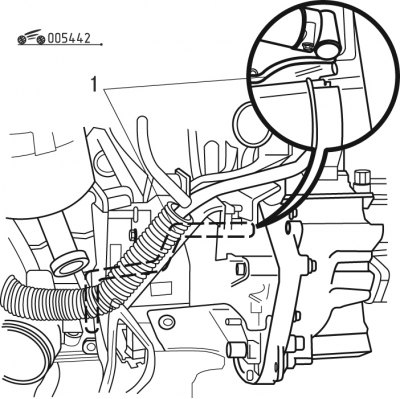

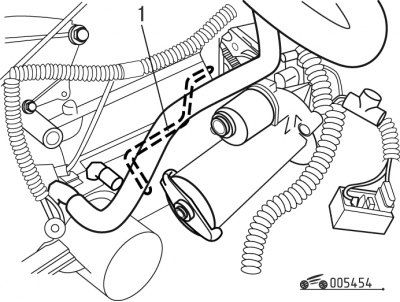

Pic. 4.42. Flywheel fixing: 1 - stopper

- turn the crankshaft with a wrench and lock the flywheel with lock 1 (pic. 4.42);

- disconnect the wire from the negative terminal of the battery;

- remove the protective cover and take it aside;

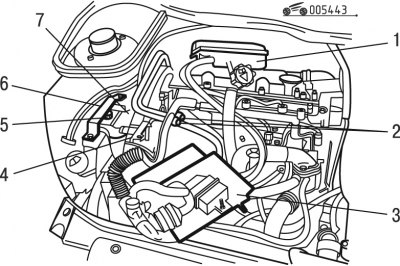

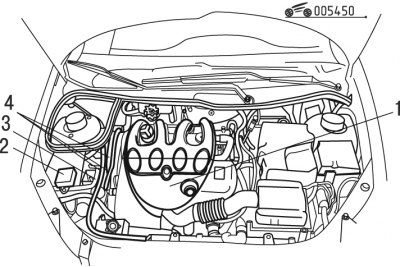

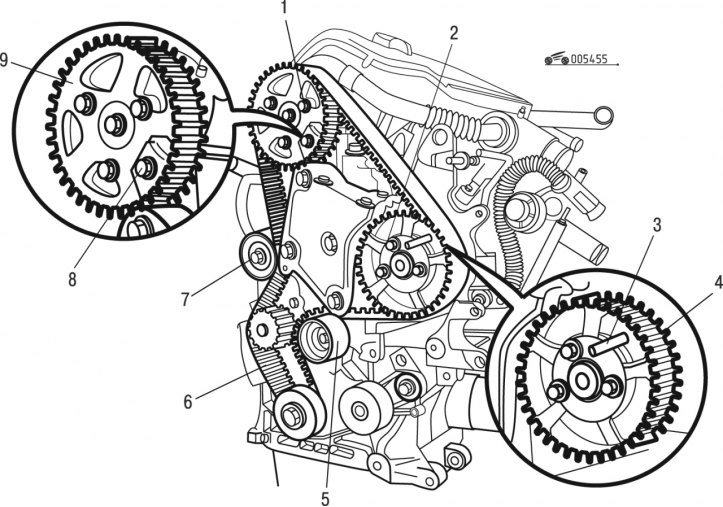

Pic. 4.43. Removing parts in the engine compartment: 1 - expansion tank; 2 - fuel pipes; 3 - control unit; 4 - right engine support; 5 - emphasis; 6 - jumper; 7 - timing case

- remove expansion tank 1 (pic. 4.43);

- remove the electronic control unit with the bracket;

- disconnect and take aside fuel pipes 2;

Note. Close the holes in the tubes with plugs.

- remove jumper 6;

- remove stop 5;

- remove the cover 7 of the gas distribution mechanism;

- hang the engine using a traverse for a special eye or lift it with a jack installed under it;

- cover the radiator cells with a sheet of thick cardboard cut to the size of the radiator;

- remove the right support 4 engine mounts;

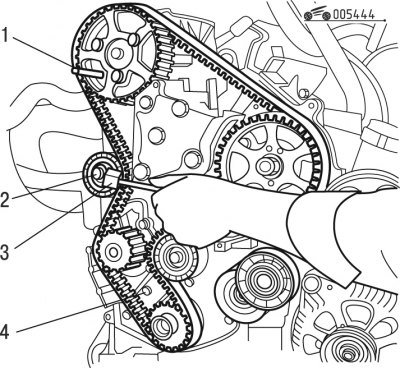

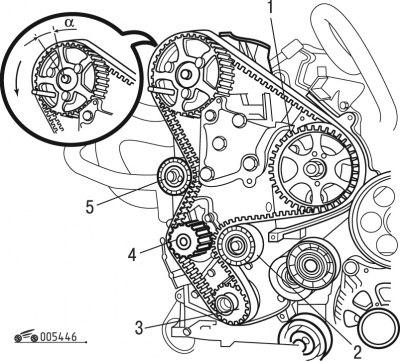

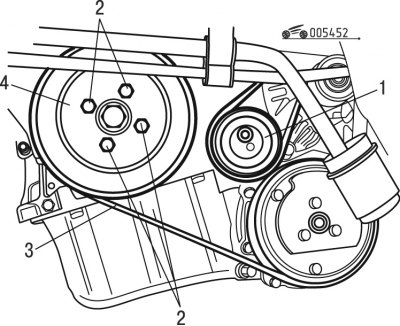

Pic. 4.44. Removing the timing belt: 1 - fixture; 2-tensioner; 3 - tensioner roller; 4 - toothed belt

- fix the camshaft pulley with tool 1 (pic. 4.44);

- loosen the fastening of the tensioner roller 2, then re-tighten the fastening in the most loosened position with a torque of 1 Nm;

- remove toothed belt 4.

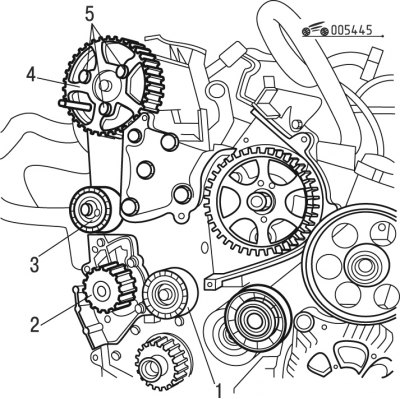

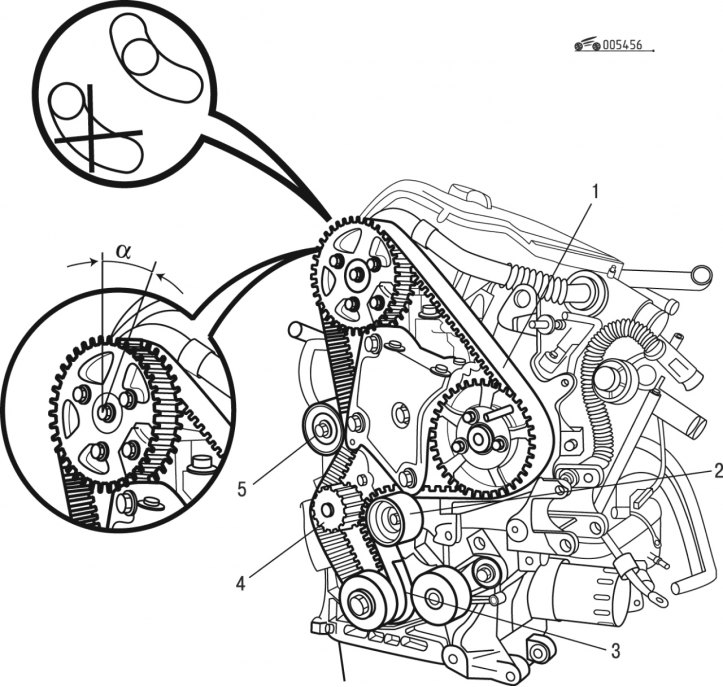

Pic. 4.45. Preparing to install the timing belt: 1, 3 - rollers; 2 - water pump pulley; 4 - camshaft pulley; 5 - bolts

Install the toothed belt in the following order:

Attention! Make sure rollers 1 and 3 are (pic. 4.45) and pulley 2 of the water pump rotate freely, without gaps and jams. Also make sure that the rollers do not make noise or splatter grease.

- unscrew bolts 5;

- make sure that pulley 4 rotates freely;

- tighten bolts 5 by hand;

- unscrew bolts 5 by 1/6 turn;

- turn pulley 4 clockwise until it stops;

Pic. 4.46. Timing belt installation: 1 - pulley; 2, 5 - rollers; 3 - fixture; 4 - water pump pulley

- install the belt on the crankshaft pulley, fixing the belt with tool 3 (pic. 4.46) and then on the guide roller 2;

- install the timing belt on pulley 1;

- turn the camshaft pulley slightly against its working movement to put the belt on the gear;

Attention! Angular movement (a) pulley relative to the belt should not exceed the width of one tooth.

- put the belt on the roller 5 of the tensioner 5 and on the pulley 4 of the water pump;

- bring the roller 5 of the tensioner to the belt;

- tighten the tensioner roller mounting bolt with a preliminary force of 1 Nm;

- remove tool 3.

Install the belt using the device in the following order:

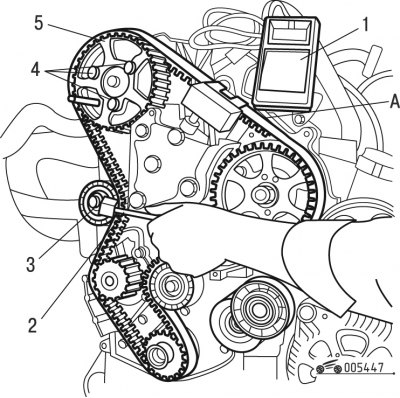

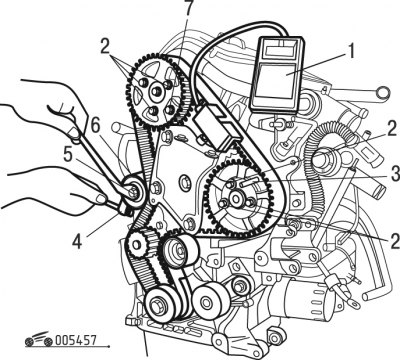

Pic. 4.47. Timing belt pretension: 1 - device-device; 2 - fixture; 3, 4 - bolts; 5 - pulley; A - belt span

- install tool 1 (pic. 4.47);

Note. Make sure that the device 1 does not touch the surrounding mechanisms.

- turn the tensioner roller counterclockwise using tool 2;

- tighten the belt (106±2) conventional SEEM units;

- tighten bolt 3 to 2.3 Nm (without changing the position of the roller);

- remove tool 1;

Attention! Turning away a bolt 4 of a pulley 5, be convinced that these bolts do not rest against a loop. Otherwise, proceed to install the timing belt again.

- screw the bolts 4 all the way into the pulleys;

- tighten bolts 4 to 20 Nm;

- remove clips 1 (see fig. 4.42 and 4.44);

- turn the crankshaft 8 revolutions in the direction of working rotation.

Attention! Never turn the crankshaft in the opposite direction.

The final tension of the toothed belt is carried out in the following order:

- install clips 1 (see fig. 4.42 and 4.44);

- loosen the tightening torque of the bolts 4 (see fig. 4.47);

- tighten bolts 4 by hand;

- unscrew bolts 4 by 1/6 turn;

- loosen the tightening torque of bolt 3;

- install tool 1 on span A of the belt;

- turn the tensioner roller counterclockwise using tool 2;

- tighten the belt (54±2) conventional SEEM units;

- tighten bolt 3 to 23 Nm without changing the position of the roller;

- tighten bolts 4 to 20 Nm;

- remove tool 1 to relieve internal stresses;

- reinstall tool 1. Belt tension should be 51-57 SEEM;

Note. If the belt tension obtained is outside the specified values, loosen the belt and start re-tensioning.

- remove the device-adaptation 1;

- remove clips 1 (see fig. 4.42 and 4.44).

Check the correct adjustment of the gas distribution mechanism in the following order:

- turn the crankshaft 2 turns in the direction of working rotation and do not turn it in the opposite direction;

- re-attach latch 1 (see fig. 4.42);

Attention! Visually check that the distance between the hole in the camshaft flange and the hole for the corresponding retainer is no more than 1 mm.

- remove latch 1.

Finish installing the timing belt in the following order:

- install the lower casing of the gas distribution mechanism;

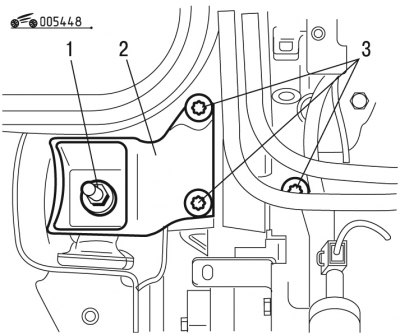

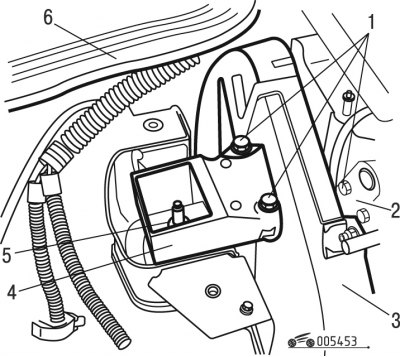

Pic. 4.48. Engine mount installation: 1 - nut; 2 - support; 3 - bolts

- install support pad 2 (pic. 4.48) engine;

- tighten three bolts 3 to 45 Nm;

- tighten nut 1 to 45 Nm;

- install cover 7 (see fig. 4.43) gas distribution mechanism;

- install the stop 5, tightening the fastening parts to a torque of 32 Nm;

- install jumper 6, tightening the fastening parts to 21.5 Nm;

- fix the flywheel with a stopper;

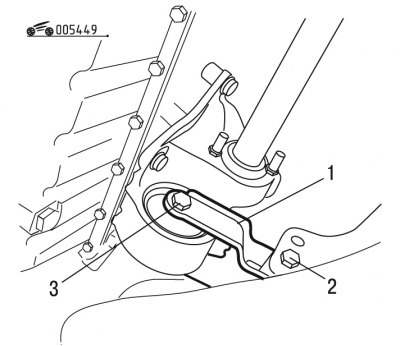

Pic. 4.49. Reactive arm installation: 1 - lever; 2, 3 - bolts

- install reaction arm 1 (pic. 4.49) engine mounts;

- tighten bolt 3 to 50 Nm;

- tighten bolt 2 to 35 Nm;

- install the accessory drive pulley;

- drive with a tap M163150 in the crankshaft the internal thread for the pulley mounting bolt;

- clean the threads on the bolt with a brush;

- tighten the bolt to 40 Nm after applying LOCTITE FRENETANCH sealant;

- Tighten the bolt by 50°using a FACOM D360 tool);

- check tightening torque 195 Nm;

- install the accessory drive belt;

- remove the flywheel retainer;

- install the shield, tightening the fasteners to a torque of 18 Nm;

Attention! The exhaust system clamp should be replaced regularly with a new one.

- install details of system of release of the fulfilled gases;

- tighten the wheel bolts to 85 Nm.

Complete the subsequent installation in the reverse order of removal, and then program all electronic devices.

DW8 engine

When removing and installing a toothed belt at Peugeot service centers, use the following special tool:

- belt tension gauge - SEEM C.TRONIC 105.5M;

- crankshaft lock - 0188-D;

- camshaft fixing tool with bolt M83803125 - 0188-E;

- high pressure pump adjuster - 0188-H;

- belt support - 0188-K;

- flywheel stopper - 0188-F;

- crankshaft wrench - 0117-EZ.

- traverse - 0102-D;

- hanging hooks - 0102-J;

- auxiliary lever for tension - 0188-J1.

Remove the timing belt in the following order:

- disconnect the wire from the negative terminal of the battery;

Pic. 4.50. Removing parts in the engine compartment: 1 - protective cover; 2 - electronic unit; 3, 4 - tubes

- remove protective cover 1 (pic. 4.50);

- disconnect fuel pipes 4 and 3;

- disconnect the electronic unit 2;

- remove the front right wheel;

- remove the front right mudguard;

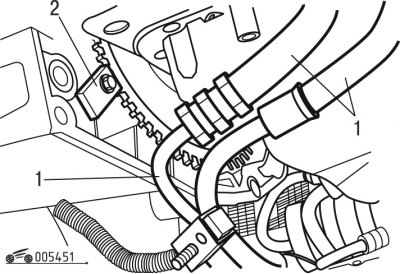

Pic. 4.51. Removing the power steering pipes: 1 - tubes; 2 - fixture

- disconnect and move aside tube 1 (pic. 4.51) power steering, passing in the engine area;

- remove the protective board;

- install tool 2;

- loosen the tensioner pulley;

Pic. 4.52. Removing the accessory drive belt: 1 - tension roller; 2 - bolts; 3 - belt; 4 - pulley

- remove the auxiliary drive belt, for which remove the tension roller 1 (pic. 4.52), unscrew bolts 2 and remove pulley 4 of the crankshaft;

- cover the radiator cells with a sheet of thick cardboard cut to the size of the radiator;

- install the crossbar with chains and, hooking them on the engine eye, tighten;

Pic. 4.53. Removing the engine mount: 1 - bolts; 2 - eye; 3 - timing case; 4 - support; 5 - nut; 6 - gasket

- move gasket 6 aside (pic. 4.53);

- unscrew nut 5;

- unscrew three bolts 1;

- remove the pillow of support 4 of the engine;

- remove the parts of the casing 3 of the gas distribution mechanism;

- remove the lower casing of the gas distribution mechanism;

- remove tool 2 (see fig. 4.51);

- turn the crankshaft with a key;

Pic. 4.54. Flywheel fixing: 1 - fixture

- fix the engine flywheel with tool 1 (pic. 4.54), without removing the starter;

Pic. 4.55. Fixing the camshaft pulley: 1, 2 - bolts; 3, 8 - clamps; 4, 9 - pulleys; 5 - roller; 6 - belt; 7 - tensioner roller

- fix the camshaft pulley with tool 8 (pic. 4.55);

- install high pressure fuel pump (injection pump) using tool 3;

- loosen the fastening of the roller 7 of the tensioner;

- re-tighten the fastener in the most loose position;

- remove toothed belt 6.

Install the timing belt in the following order:

Note. Make sure rollers 5 and 7 rotate freely (without backlash and jamming). Also make sure that the rollers do not make noise or splatter grease.

- unscrew bolts 1 and 2 (see fig. 4.55);

- make sure that pulleys 4 and 9 rotate freely on their hub;

- tighten bolts 1 and 2 by hand and then loosen 1/6 turn;

- turn two pulleys 4 and 9 clockwise until it stops in the buttonhole;

Pic. 4.56. Timing belt installation: 1 - belt; 2 - roller; 3 - fixture; 4 - water pump pulley; 5 - tensioner roller

- install the belt on the crankshaft pulley, fixing the belt with tool 3 (pic. 4.56);

- install guide roller 2;

- install the timing belt 1 on the pulley;

- turn the camshaft pulley slightly against the direction of the working movement to put the belt on the pulley;

Attention! Angular movement (a) pulley relative to the belt should not exceed the width of one tooth.

- put the timing belt on the tensioner pulley 5 and on the water pump pulley 4;

- bring the roller 5 of the tensioner to the belt;

- tighten the tensioner roller mounting bolt with a preliminary torque of 1 Nm;

- remove tool 3.

Pre-tension the timing belt in the following order:

Pic. 4.57. Timing Belt Tension: 1 - device; 2 - bolts; 3, 7 - clamps; 4 - fixture; 5 - nut; 6 - tensioner roller

- install the device on the belt 1 (pic. 4.57);

Note. Make sure that the device does not touch the surrounding mechanisms.

- turn tensioner pulley 6 counterclockwise using tool 4;

- get the tension (106±2) conventional SEEM units;

- tighten nut 5 to 18 Nm without changing the position of roller 6;

- remove device 1;

Attention! When unscrewing the bolts 2 fastening pulleys 4 and 9 (see fig. 4.55) make sure the bolts are 2 (see fig. 4.57) do not rest on the buttonhole. Otherwise, proceed to reinstall the timing belt.

- screw bolts 2 all the way into the pulleys;

- tighten bolts 2 to 23 Nm;

- remove retainer 1 (see fig. 4.54) and clamps 3 and 8 (see fig. 4.55);

- turn the crankshaft 8 revolutions in the direction of working rotation (clockwise);

Attention! Never turn the crankshaft in the opposite direction.

The final tension of the timing belt is carried out in the following order:

- install latch 1 (see fig. 4.54) and clamps 3 and 8 (see fig. 4.55);

- loosen the tightening torque of the bolts 2 (see fig. 4.57);

- loosen the tightening torque of the nut 5;

- tighten bolts 2 by hand, and then unscrew 1/6 turn;

- install the device 1 on the span A of the belt;

- turn tensioner pulley 6 counterclockwise using tool 4;

- tighten the belt (41±2) conventional SEEM units;

- tighten nut 5 to 18 Nm without changing the position of roller 6;

- tighten bolts 2 to 23 Nm;

- remove device 1;

- reinstall device 1;

Note. The tension value should be equal to 38-42 conventional SEEM units.

Attention! If the belt tension obtained is outside the specified values, loosen the belt tension and proceed with re-tensioning.

- remove device 1 (see fig. 4.57), latch 1 (see fig. 4.54) and clamps 3 and 8 (see fig. 4.55).

Check the correct adjustment of the gas distribution mechanism in the following order:

- turn the crankshaft 2 turns in the direction of working rotation and do not turn it in the opposite direction;

- re-attach latch 1 (see fig. 4.54);

- check visually and make sure that the deviations between the holes of the camshaft hubs and the injection pump and the holes for their alignment are no more than 1 mm;

- remove retainer 1.

Complete the installation of the timing parts in the following order:

- install the lower casing of the gas distribution mechanism;

- install support pad 4 (see fig. 4.53) engine;

- install the parts of the casing of the gas distribution mechanism;

- tighten nut 5 (see fig. 4.53) torque 45 Nm;

- tighten three bolts 1 to 45 Nm;

- fix the flywheel with tool 2 (see fig. 4.51);

- install pulley 2 (see figure 4.52) crankshaft;

- tighten bolts 4 to 10 Nm;

- install tension roller 1;

- install the accessory drive belt as described above;

- install the shield, tightening the details of its fastening with a torque of 19 Nm;

- Install the rest of the components and mechanisms in the reverse order of removal.