Fast idle adjustment

Adjust the fast idle mode on a cold engine in the following order:

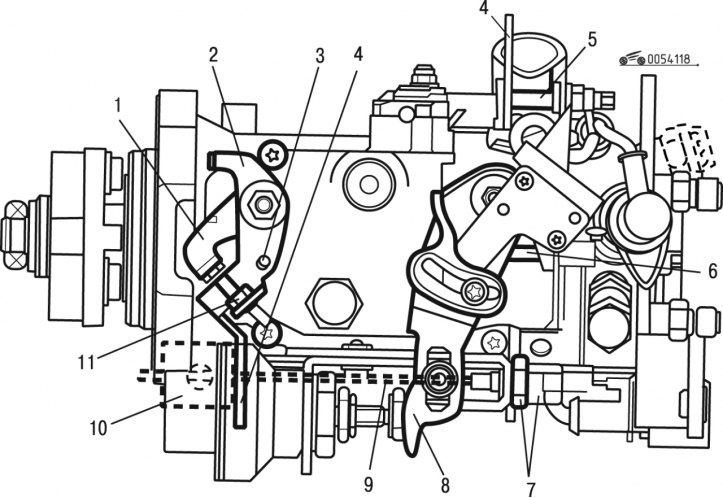

Pic. 4.118. High pressure fuel pump adjustment: 1, 2, 8 - levers; 3 - pin; 4 - gasket; 5 - stop screw; 6 - restrictive screw; 7 - cable sheath retainer; 9 - cable; 10 - clamp; 11 - idle screw

- check that lever 2 (pic. 4.118) rested on the right stop;

- if the lever does not rest, adjust the tension of the cable 9 using the clamp 10;

- finally adjust the tension using the latch 7 of the cable sheath.

Adjust the fast idle mode on a hot engine in the following order:

- make sure that cable 9 is not overtightened;

- compared to a cold one on a hot engine, the cable should move more than 6 mm.

Adjustment of the accelerator drive mechanism

Adjust the accelerator drive mechanism in the following order:

Note. The engine must be warm before adjustment (the electric fan should run for two cycles). The fast idle drive must be free, clearance A must be within 0.5-1 mm.

- fully depress the accelerator pedal;

- make sure that the lever 8 rests against the limit screw 6. Otherwise, change the position of the accelerator cable tension locking pin;

- make sure that in the idle position the lever 8 rests against the locking screw 5.

Adjustment of the engine stabilization mechanism (residual fuel supply)

Adjust the engine stabilization mechanism in the following order:

- install gasket 4 (see fig. 4.118) 3 mm thick between the load lever 8 and the thrust bolt 5, which prevents the engine from stopping;

- press the lever 1 to stop the engine;

- insert pin 3 with a diameter of 3 mm into lever 2;

- adjust engine speed (1700±100) min-1, by turning stop 5;

- remove pin 3;

- remove the dipstick.

Engine idle adjustment

Adjust the idle speed of the crankshaft with screw 11 (see fig. 4.118).

With air conditioning, crankshaft speed - (875±25) min-1.

Without air conditioning, crankshaft speed - (800±25) min-1.

Control of engine operation in deceleration mode

Check the operation of the engine in the deceleration mode in the following order:

- press lever 8 (see fig. 4.118) throttle valve and achieve an engine speed of 3500 min-1;

- release the load lever 8.

Note. Deceleration should occur in the range of 2.5-3.5 s.

Speed reduction should be approximately 50 min-1 in relation to the value of the frequency of rotation of the crankshaft at idle. Otherwise, you should follow the table. 4.11.

Table 4.11. Control of engine operation in deceleration mode

| Marked deviations | Elimination Method |

| Too fast deceleration | |

| Engine detects a tendency to stop running, stalls | Tighten screw 5 (see fig. 4.118)) a quarter turn |

| Too slow deceleration | |

| Speed exceeds idling | Loosen screw 5 a quarter of a turn |

Attention! In each case, the idle speed should be checked for possible correction.