- cross member 0102-D;

- lifting and hanging chain 0102-M;

- pin for fixing the pulley in a fixed position - 0188-V;

- high pressure fuel pump pulley removal kit - 0188-R;

- tubing wrench - 1603-G (4220-TD);

- plug set 0188-T;

- compression sleeve 1603-A/E/B/D [4220-T (B-J)].

Removal of high pressure fuel pump perform in the following order:

Attention! Each time the high pressure hoses are removed, they must be replaced with new ones.

- remove the timing belt, see «Gas distribution mechanism (timing)»;

- install the upper engine mount bracket, slightly tightening the mounting bolts;

- disconnect and move the wiring harness;

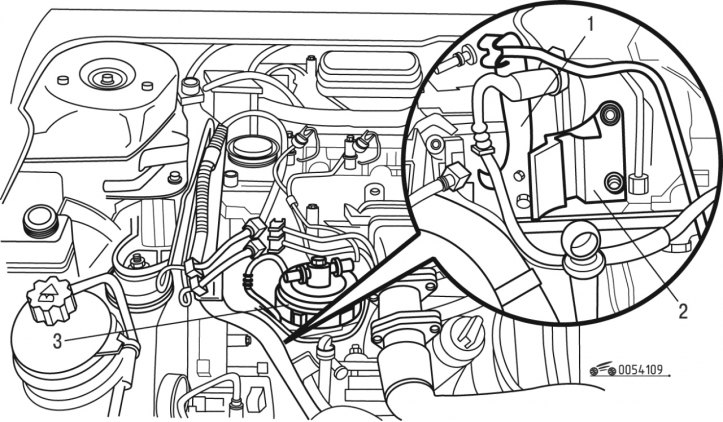

Pic. 4.109. Removing the fuel filter bracket: 1 - wiring harness; 2 - bracket; 3 - fuel filter

- move aside the harness bracket 1 (pic. 4.109) electrical wiring;

- disconnect the contact connectors;

- drain the liquid from the fuel filter housing and move it;

- close the holes with plugs using the tool;

- remove the bracket 2 of the filter housing;

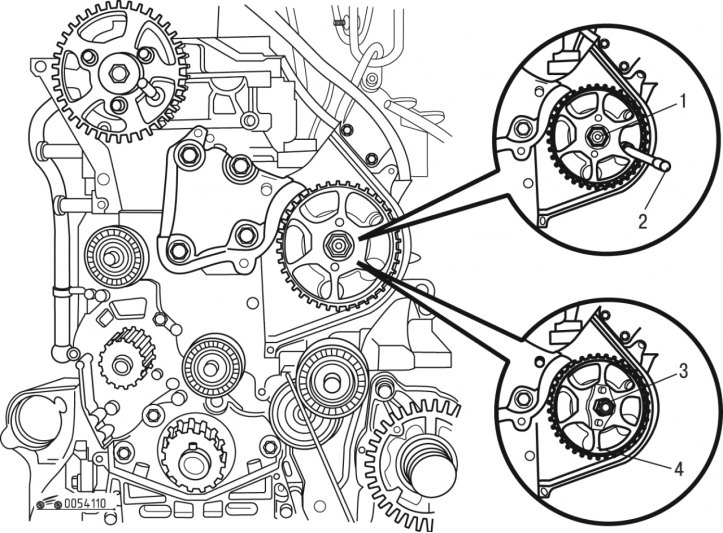

Pic. 4.110. Removing the injection pump pulley: 1 - nut; 2, 3 - fixtures; 4 - pulley

- unscrew nut 1 (pic. 4.110) fastening the injection pump pulley using tool 2;

- remove the pulley 4 of the injection pump drive using tool 3;

- clean the fuel lines from dirt before unscrewing them;

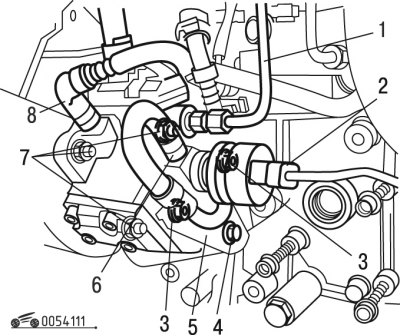

Pic. 4.111. Removing the injection pump: 1, 6, 8 - fuel lines; 2 - fuel line connection; 3, 4 - bolts; 5 - bracket; 7 - fasteners

- apply a locking compound in place A (pic. 4.111);

- take aside fuel lines 6 and 8;

- close the holes with plugs using the tool;

- remove the high pressure fuel line 1;

- unscrew bolts 3;

- loosen the tightening torque of bolt 4;

- tilt bracket 5;

- remove fasteners 7;

- remove the high pressure fuel pump.

Install the injection pump in the reverse order of removal, observing the following requirements:

Attention! Replace the high pressure fuel lines regularly.

- tightening elements 7 (see fig. 4.111) fasten with a torque of 22.5 Nm;

- tighten bolts 3 and 4 with a torque of 22.5 Nm;

- hand-tighten connection A;

- tighten nut 1 (see fig. 4.110) fastening the pulley with a torque of 50 Nm;

- install the fuel lines of the high pressure circuit of the power supply system and tighten the fittings by hand;

- tighten fuel line 1 (see fig. 4.111) torque 22.5 Nm using tools;

- check the tightness of the power system connections by starting the engine and setting the crankshaft speed to 1000 min-1. Press the accelerator pedal several times, bringing the crankshaft speed to 3500 min-1.