- label 1 (in the form of a spot of blue paint -class 1 nozzle);

- label 2 (in the form of a spot of green paint -class 2 nozzle).

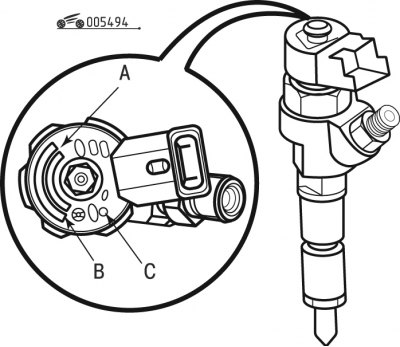

Pic. 4.94. Injector markings: A - supplier; B - identification number of the Peugeot company; C -class identification

In the marking shown in Fig. 4.94, are specified:

- provider (A);

- Peugeot identification number (B);

- class identification (C).

Attention! When replacing injectors, 4 injectors of the same class must be installed on the engine.

When removing and installing fuel injectors at Peugeot service centers, use the following special tool:

- tubing wrench - 1603-F (4220-TD);

- tubing wrench - 1603-G (4220-TC);

- plug set - 0188-T;

- compression sleeve 1603-A/E/B/D [4220-T (B-G-J)].

Remove the fuel injectors in the following order:

- remove the protective casing of the engine;

- disconnect the wire from the negative terminal of the battery;

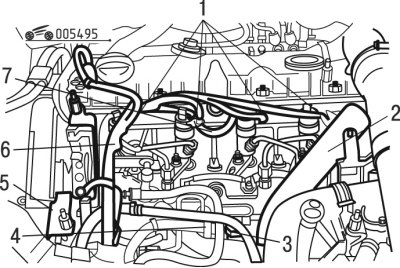

Pic. 4.95. Removing parts of the fuel system: 1 - contact connectors; 2 - tube; 3, 4 - sensors; 5 - support; 6 - wiring harness; 7 - branch pipe

- disconnect sensors 3 and 4 (pic. 4.95);

- disconnect the connectors 1 of the injectors;

- move aside the tube 2 of the oil aerosol catcher;

- take aside the wiring harness 6;

Attention! Each time the high pressure hoses are removed, they must be replaced with new ones.

- remove branch pipe 7 for fuel return;

- close the holes with the tool;

- remove support 5;

Attention! Clean the fuel line fittings before unscrewing them.

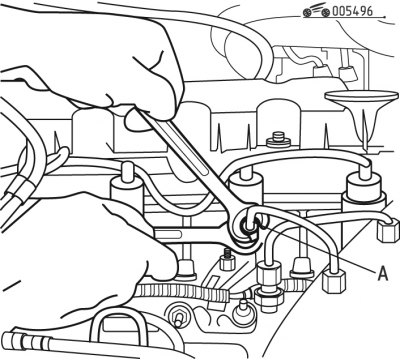

Pic. 4.96. Applying a locking compound in zone A

- apply locking compound in zone A (pic. 4.96);

- unscrew the connecting elements;

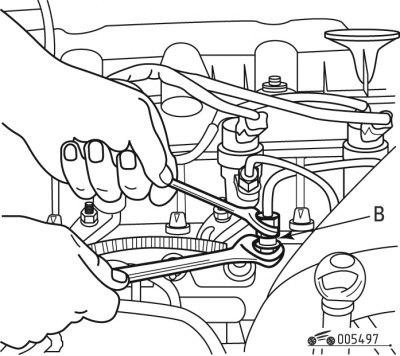

Pic. 4.97. Applying a locking compound in zone B

- apply locking compound in zone B (pic. 4.97);

- unscrew the connecting elements on the fuel distributor;

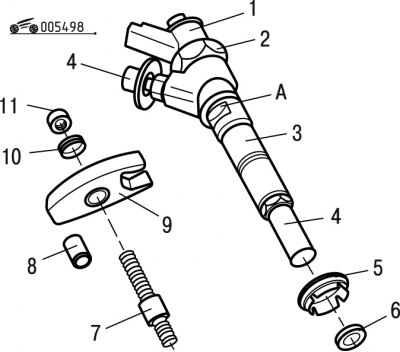

Pic. 4.98. Fuel Injector Details: 1, 4 - plugs; 2, 11 - nuts; 3 - nozzle; 5 - sealing ring; 6 - leather gasket; 7 - hairpin; 8 - thrust washer; 9 - bracket; 10 - washer

- remove the four high pressure pipes;

Attention! Don't touch the nut 2 (pic. 4.98).

- unscrew the nuts of 11 nozzles;

- remove washers 10;

- remove brackets 9 fastening nozzles;

- remove nozzles 3;

- remove sealing rings 5;

- remove leather pads 6;

- remove thrust washers 8;

Note. If it is not possible to remove the injector, remove the pin 7 with the lock nut, then use a flat wrench to turn the injector in the area of flat A.

- plug holes 1 and 4 of the injectors.

Install the fuel injectors in the following order:

Attention! WarningsReplace the removed high-pressure fuel lines. When unscrewing nuts 11, studs 7 may unscrew together with nuts, in this case, when reinstalling the studs, be sure to orient the studs in the correct direction (do not install upside down).

- screw the studs into the cylinder head with the nut and locknut, tightening to 7.5 Nm;

Attention! When reinstalling, observe the correct bending direction of the bracket 9. Observe the correct mounting direction of the washers 10.

- remove the plugs from the nozzle holes;

- install thrust washers 8;

- install new leather gaskets 6;

- install new sealing rings 5;

- install nozzles 3, fixing them with brackets 9;

- install washers 10;

- install new nuts 11;

- fix the high pressure fuel lines on the injectors and fuel distributor;

- tighten nuts 11 to 30 Nm;

- apply locking compound in zone A (see fig. 4.96);

- tighten the fastening of the high-pressure fuel lines using tools to a torque of 20 Nm;

- apply locking compound in zone B (see fig. 4.97);

- install caliper 5 (see fig. 4.95);

- install branch pipe 7;

- reinstall wiring harness 6;

- reinstall pipe 2;

- connect the connectors 1 to the injectors;

- connect the wire to the negative battery terminal;

- check the tightness of the connections by setting the engine speed to 1000 min-1 and pressing the accelerator pedal, setting the crankshaft speed to 3500 min-1.

Complete installation in the reverse order of removal.