Remove the gearbox in the following order:

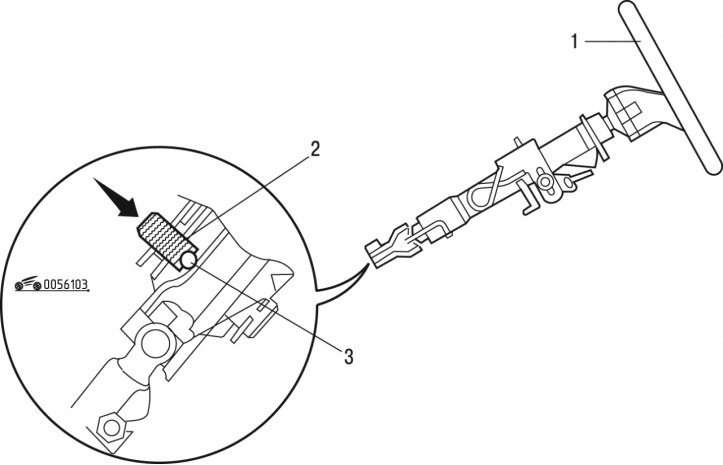

Pic. 6.103. Steering column offset: 1 - steering wheel; 2 - button; 3 - hinge

- before removing the subframe, install the steering column with steering wheel 1 (pic. 6.103) to the bottom position and move back as far as possible;

- press the button 2 on the pointer of the cardan joint 3 and fix the column;

- unscrew the nut securing the left wheel drive shaft;

- lift the car;

- remove the exhaust pipe to avoid damaging the flexible bellows;

- remove the left front wheel drive shaft;

- shift the front wheel drive shaft on the right;

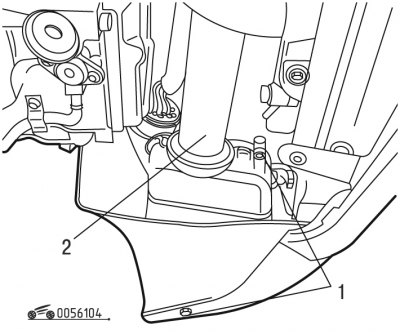

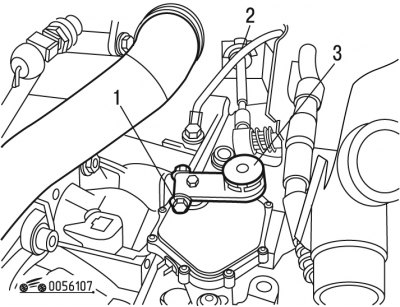

Pic. 6.104. Left mudguard: 1 - bolts; 2 - air intake nozzle

- unscrew bolts 1 (pic. 6.104) and remove the nozzle 2 of the air intake;

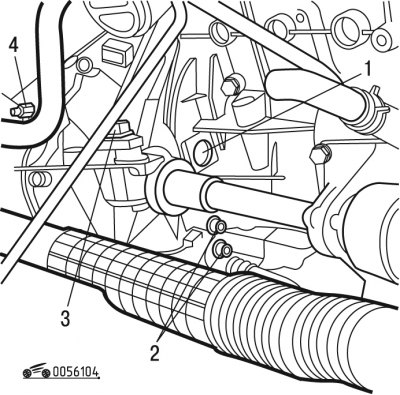

Pic. 6.105. Disconnecting the connector: 1 - nut; 2 - bolts; 3 - pin connector; 4 - nut

- unscrew nut 4 (pic. 6.105), three nuts 1, bolts 2 and disconnect the connector 3;

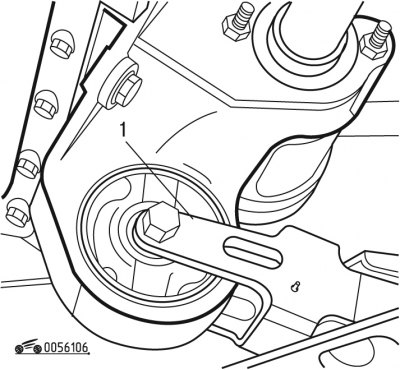

Pic. 6.106. Detachable traction: 1 - thrust

- disconnect rod 1 (pic. 6.106);

- unscrew the starter mounting bolts, take it aside without disconnecting it;

- unscrew the lower bolts securing the gearbox to the engine;

- lower the car;

- disconnect the wires from the battery terminals;

- remove the battery cover;

- remove the battery and its pallet;

Pic. 6.107. Disconnecting the control rod: 1 - bolt; 2 - clamp; 3 - ball bearing element

- unscrew bolt 1 (pic. 6.107);

- remove element 3 of the ball joint using a tool;

- remove clamp 2;

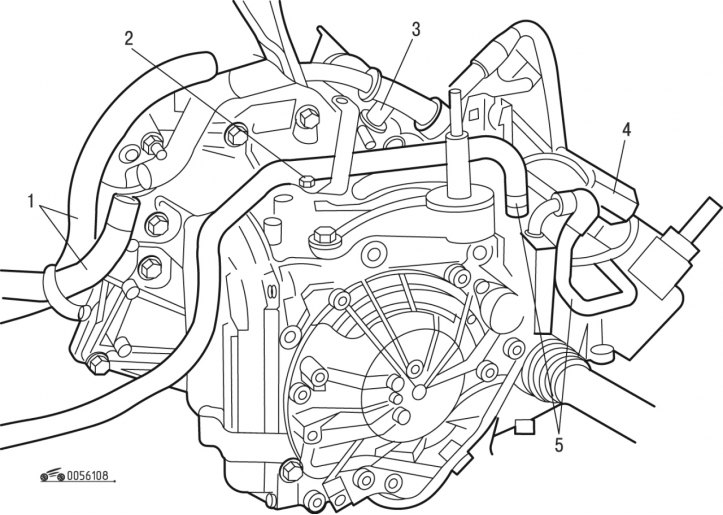

Pic. 6.108. Removing external parts: 1 - wiring harnesses; 2 - support; 3 - speed sensor; 4 - connector; 5 - pipelines

- install the tool on the pipelines 5 (pic. 6.108);

- remove the support fastening 2;

- remove the speed sensor 3;

- disconnect pipelines 5;

- move aside the wiring harnesses 1 and disconnect the connector 4;

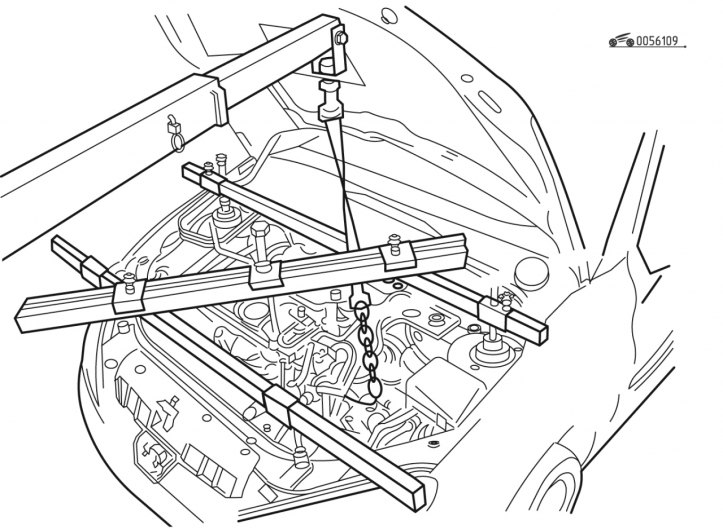

Pic. 6.109. Installing the cross member

- Install the crossbar to lift the automatic transmission as shown in fig. 6.109;

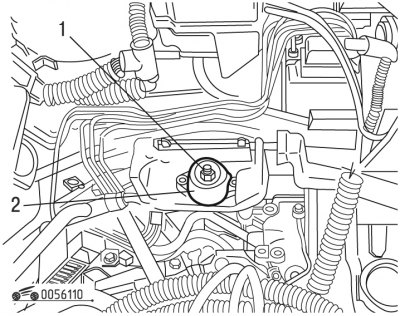

Pic. 6.110. Removing the support: 1 - bolt; 2 - support

- remove rubber support 2 (pic. 6.110), by unscrewing the bolt 1 using the tool;

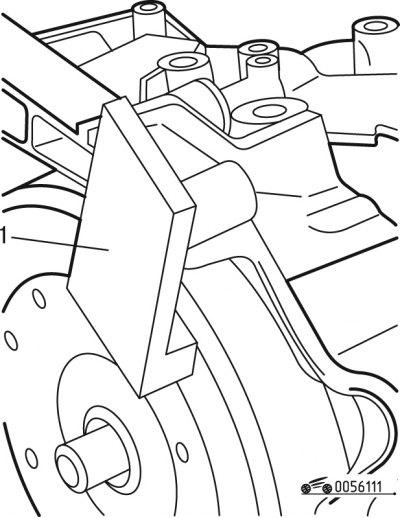

Pic. 6.111. Fixing the torque converter: 1 - fixture

- fix the torque converter by installing tool 1 (pic. 6.111);

- unscrew the upper bolts securing the gearbox to the engine, slightly tilt the power unit and remove the gearbox.

Install the automatic transmission in the following order:

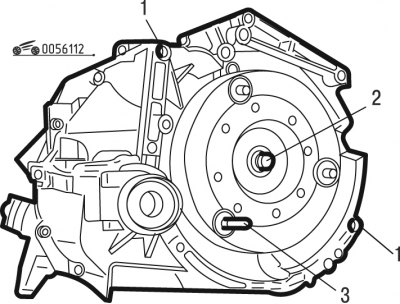

Pic. 6.112. Preparing to install an automatic transmission: 1 - mounting sleeves; 2 - shaft; 3 - pin

- make sure that the mounting sleeves 1 are present (pic. 6.112);

- reinstall pin 3;

- apply Molycote Br2 to shaft 2;

- connect the gearbox to the engine so that the pin 3 is aligned with the hole in the drive plate;

- tighten the upper bolts of the gearbox to the engine with a torque of 52 Nm;

- remove tool 1 (see fig. 6.111);

- tighten the lower bolts of the gearbox to the engine with a torque of 52 Nm;

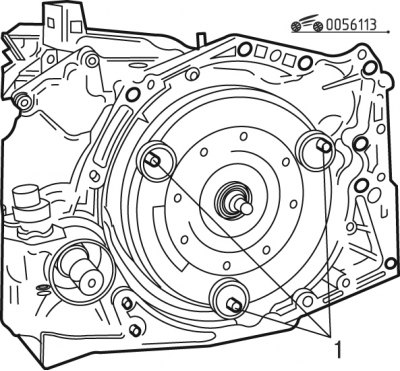

Pic. 6.113. Installing torque converter mounting nuts: 1 - nuts

- install new nuts 1 (pic. 6.113) fastening the torque converter to the plate and pre-tighten them with a torque of 10 Nm, finally tighten with a torque of 30 Nm;

- make sure there is no gap;

- install the starter and tighten its mounting bolts to a torque of 35 Nm;

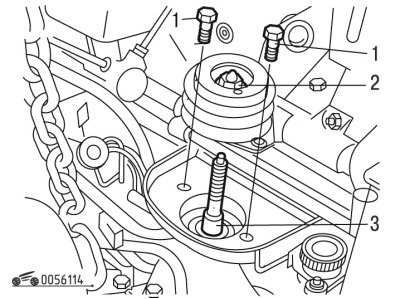

Pic. 6.114. Installing the gearbox support: 1 - bolts; 2 - nut; 3 - axis

- lubricate axle 3 with LOCTITE FRENETANCH (pic. 6.114) gearbox supports;

- install axle 3 with a washer and tighten with a torque of 50 Nm using a tool;

- install the spacer and lubricate it with PCAS SPASGRAM grease;

- install the rubber cushion of the gearbox support;

- install the nut of the 2nd axis of the support with the washer without tightening;

- install the bolts 1 for fastening the pillow without tightening;

- center the installation of the power unit before finally tightening the fastening elements of the support;

- tighten nut 2 to 65 Nm and bolts 1 to 30 Nm;

- continue installation of a transmission in an order, the return to removal;

- check the level of the working fluid in the gearbox;

- check the coolant level.

Note. In case of automatic transmission replacement, update the meter database «aging» working fluid using the diagnostic tool DIAG 2000.