Removing

Disconnect the negative battery terminal.

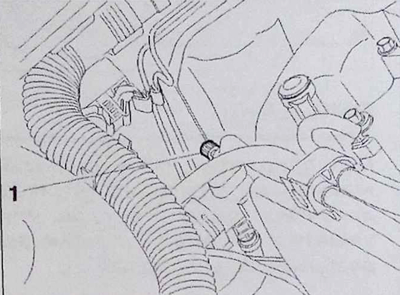

Connect the pressure measuring hose to the bleed valve (1) fuel supply circuit.

Drain the fuel into a suitable container.

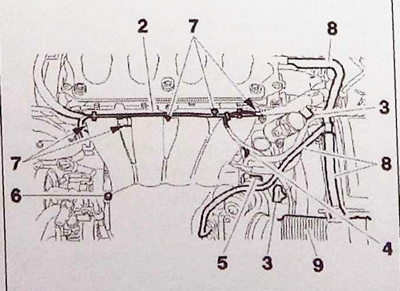

Unclip the wiring harness (2).

Disconnect connectors (3).

Disconnect the EGR valve tube (4).

Loosen the bolt (5) And (6) and nuts TU.

Remove:

- hose kit (8);

- air inlet (9);

- vacuum supply tube;

- electrical connector located under the intake manifold;

- intake manifold (see corresponding operation).

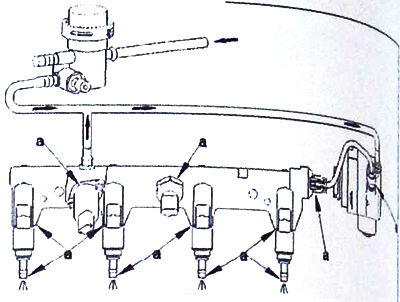

Clean the high pressure pipes before unscrewing them.

Cover the generator and starter.

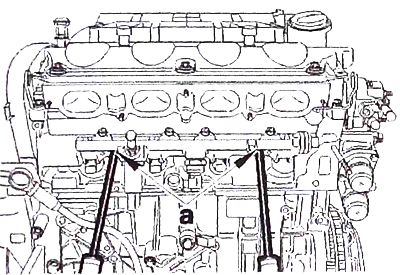

With the help of composition «Sodimac» or similar clean areas «A» (see picture).

Attention. After opening the fuel injection circuit, any cleaning is not allowed.

Disconnect the handset (11) fuel supply.

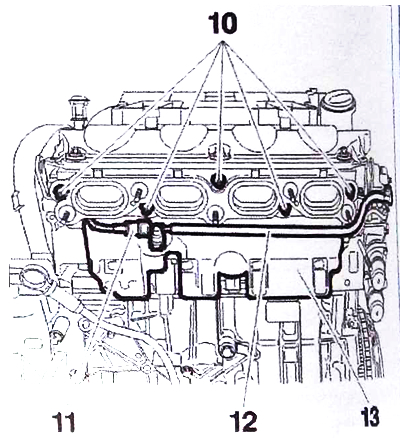

Loosen the nuts (10) soundproof pad.

Pick up the phone (12) and soundproofing element (13) fuel rail.

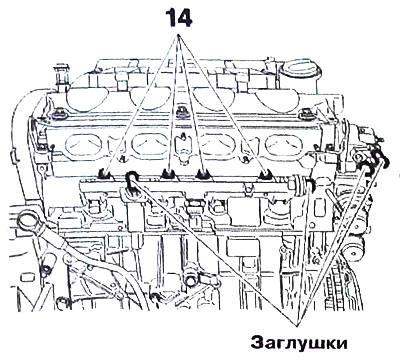

Close the fasteners on the tubes with plugs (11) fuel distribution ramp (12) and high pressure fuel pump. Loosen the fixing screws (14) and remove the fuel rail (remove manually by pulling several times).

Note. Move the injectors by turning them several times to break up the layer of deposits that has formed between the injector and the combustion chamber.

If the injection rail cannot be removed by hand, insert two flathead screwdrivers into the area «A», to lift her up.

|  |

Close the holes in the nozzles with plugs.

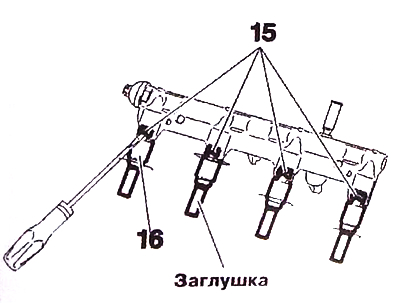

Remove the fasteners with a screwdriver (15) and nozzles (16).

Plug all open openings in the high pressure circuit.

Replacing the injector sealing washer

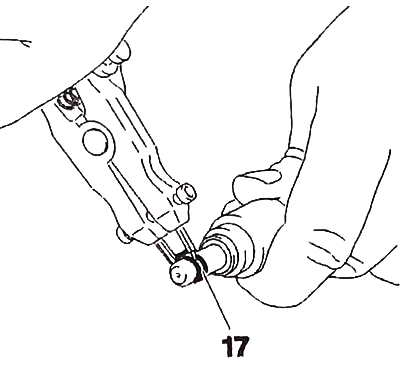

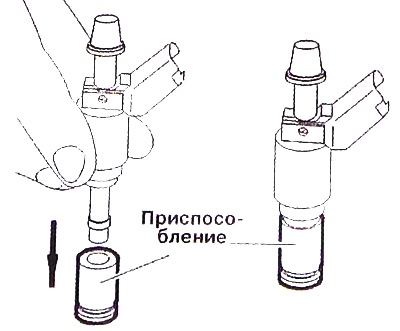

Remove sealing washer (17), being careful not to scratch the nozzle (using circlip pliers).

Clean the nozzle nozzles with a brush using Sodimac/Mecanet degreaser.

Attention. It is forbidden to clean the nozzles with a rag and compressed air.

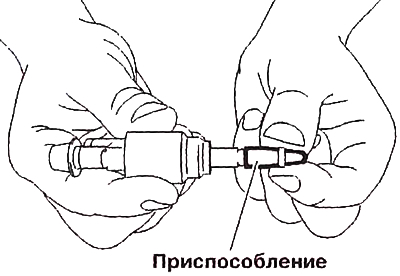

Install a new gasket in the injector groove, having previously put it on the tool bushing.

Insert the nozzle into the fixture body.

Note. After the gasket is put on the nozzle body, it must be installed in place as soon as possible.

Installation

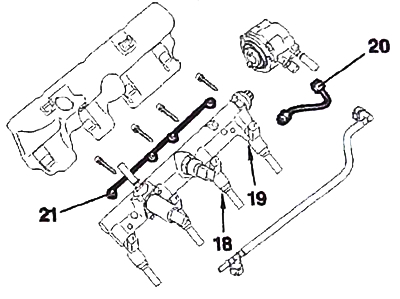

Note. Replace gaskets (18) - (19), clamps (15) and high pressure pipe (20).

Install in place:

- nozzles on the fuel distribution rail;

- new nozzle holders;

- fuel rail and its gasket (21).

Check the high pressure fuel circuit for leaks.

Install in place:

- new high pressure pipe;

- soundproofing element (13) fuel distribution rail;

- nozzle connectors.

Install the rest of the parts in reverse order.

Check the high pressure fuel circuit for leaks using a leak detector.