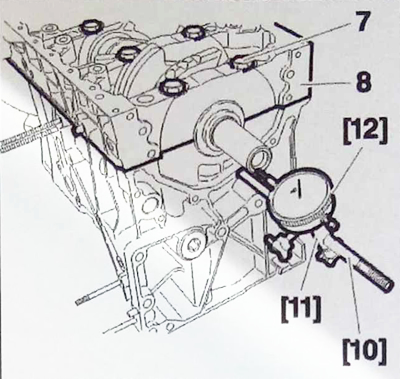

Fix indicator 12 on supports 10-11.

Reinstall the crankshaft main journal housings (8) and fix them with 10 bolts (7) (tightening torque 10 Nm).

Press axially on the crankshaft in the cylinder block.

Set the dial gauge to zero.

Press axially in the opposite direction on the crankshaft in the cylinder block.

The side clearance should be 0.06-0.15 mm.

Choose thicker side pads of the same thickness.

Loosen 10 bolts (7) and remove the crankcase of the main journals of the crankshaft (8).

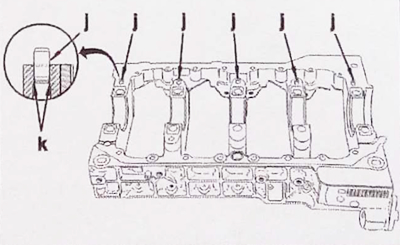

Make sure you have pins (j), replace the pins (if necessary).

Insert the pin 50% of its length into the crankcase.

Insert a pin in the zone (To) using a pin setting tool.

Fill the roller in the zone (To), to lock the pin.

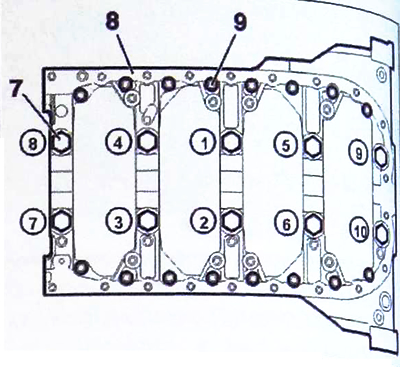

Apply a sealing compound around the crankcase perimeter of the main journal covers «Autojoint Noir». Install in place:

- crankcase covers of the main crankshaft (8);

- 10 bolts (7);

- 16 bolts (9).

Note. Tighten each bolt in turn in the sequence shown. Make sure the crankshaft turns without a command

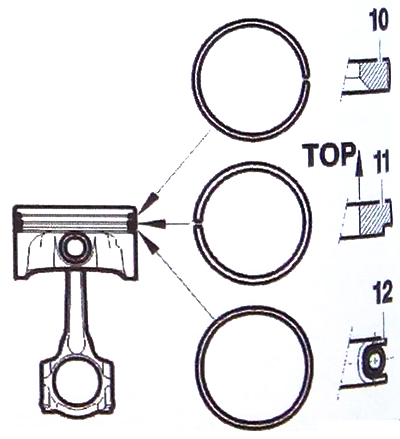

Install the piston rings with a ring clamp.

Labeled surface «Thor» sealing (second) piston ring (11) should be directed upwards.

Turn the piston ring lock (11) 180°to piston ring lock (10).

Note. Oil scraper ring (12) «Uflex» does not have a lock.

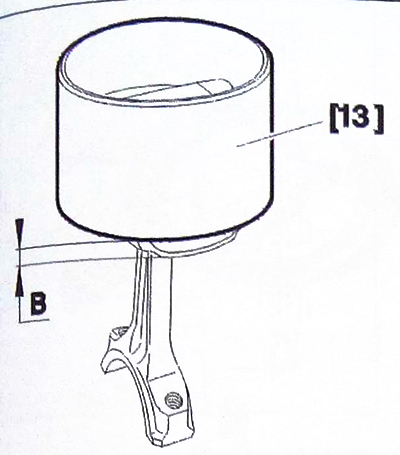

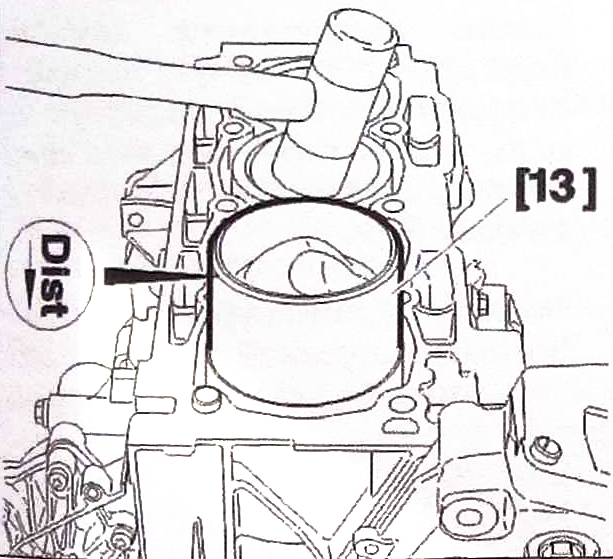

Insert the piston with the connecting rod assembly using the special sleeve 13 (lubricate the peripheral surface).

Insert part (IN) piston so that it serves as a guide for the correct installation of the entire piston. Install the top liner, predetermined class.

Lubricate the sleeves.

Focus on the marks made during disassembly (The arrow on the piston must point towards the timing drive).

Hold the piston ring mounting mandrel 13 so that it is firmly pressed against the plane of the cylinder block and located exactly in the center of the liner.

Insert the piston, making sure that the oil scraper ring is correctly installed («Uflex»).

Do the same for other assemblies.

Turn over the cylinder block.

Note. Install bearings of a predetermined class in the connecting rod caps.

Lubricate the bushings and lower bearings with engine oil.

Install the connecting rod caps.

Observe the pairing of parts: connecting rods / connecting rod caps.

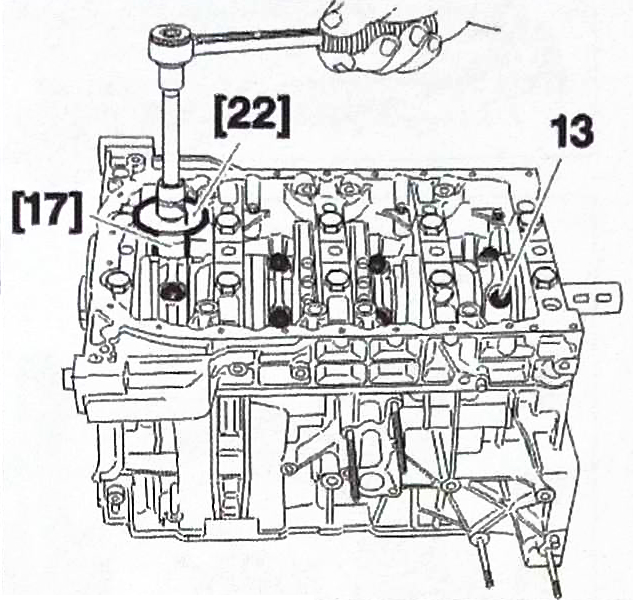

Install bolts (13) connecting rod caps (lubricate them first).

Using tools 17 and 22, pre-tighten the bolts (13) torque 23 Nm.

Perform a 45°corner tightening.

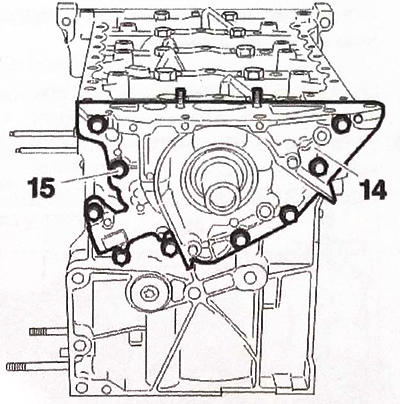

Apply a sealing paste to the mating surface of the oil pump «Autojoint Noir».

Install the oil pump (14).

Lubricate with composition «Loctite Frene-tanch» bolts (15).

Tighten the bolts (15) torque 8 Nm.

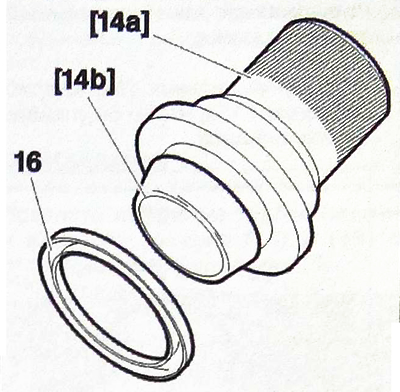

Insert tool 14b into tool 14a.

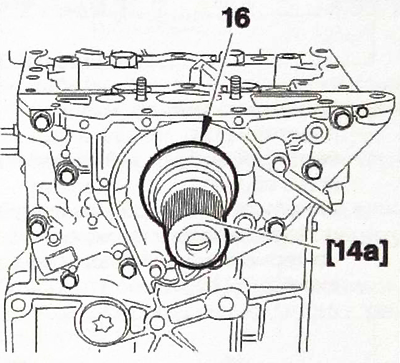

Install the oil seal (16) using tool 14a.

Remove tool 14b.

Attention. When mounting, lubricate the annular lip of the tool, but do not lubricate the outer surface of the stuffing box.

Install the oil seal (16) with tool 14a so that it rests on the cylinder block.

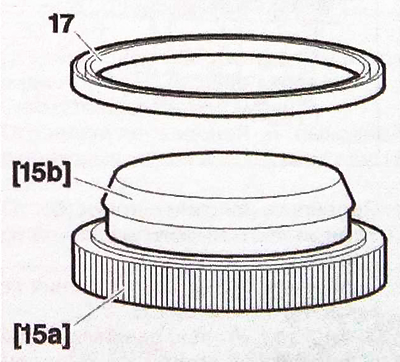

Insert tool 15b into tool 15a.

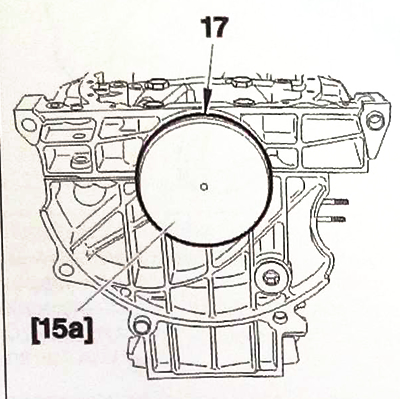

Install the sealing sleeve (17) using tool 15a.

Remove tool 15b.

Attention. When mounting, lubricate the annular lip of the tool, but do not lubricate the outer surface of the stuffing box.

Install the oil seal (17) with tool 15a so that it rests on the cylinder block.

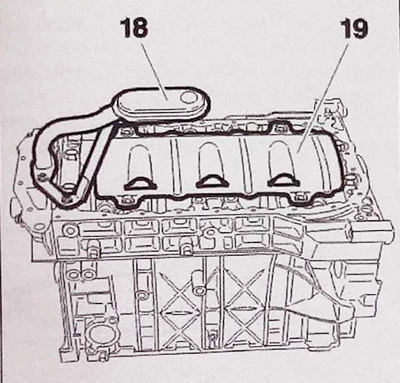

Install in place:

- plate (19);

- strainer (18) with gasket assembly;

- Apply a uniform thin layer of sealing paste to the pressing surface of the cylinder block.

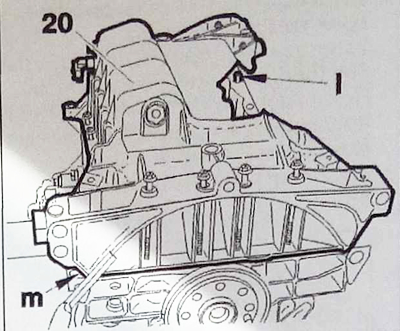

Check for key (l).

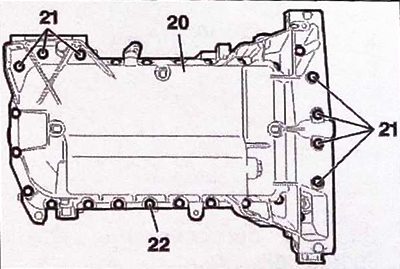

Install the oil pan (20).

Tighten the bolts until contact is made without tightening them.

Apply a polished ruler in the area (m) and adjust the position of the oil pan to align it with the surface of the cylinder block.

Tighten the bolts (21) And (22) oil pan.

|  |

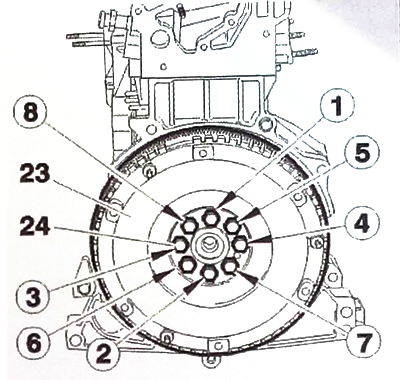

Note. Bolt holes need to be cleaned (24), before installing them.

Clean the mating surfaces of the crankshaft and flywheel.

Install the flywheel (23) and new bolts (24).

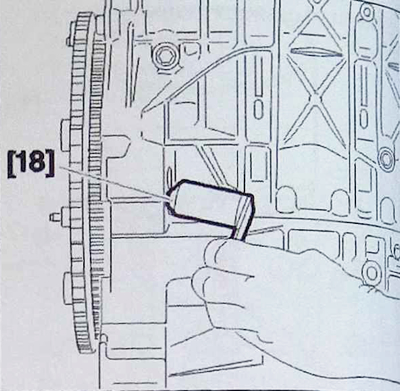

Install tool 18.

Insert bolts (24) until it touches the flywheel in the order 1-5-3-7-2-6-4-8 and tighten.

Note. Tighten the bolts one by one in the sequence shown.

Attention. Make sure dowel pins are present (n).

Set the pistons to mid stroke.

Install a new cylinder head gasket.