Note. Checking cylinders for leaks can be done as an alternative to measuring compression.

Using this method, you can measure the total amount of leakage from the engine cylinders and determine its location. A similar check can be made using a compression gauge by injecting oil into the cylinder. However, this can cause soot formation. The result will not always be decisive or accurate.

Check method

1. The engine must be warmed up to operating temperature so that the thermostat opens.

2. The piston in the cylinder under test must be at top dead center during the compression stage.

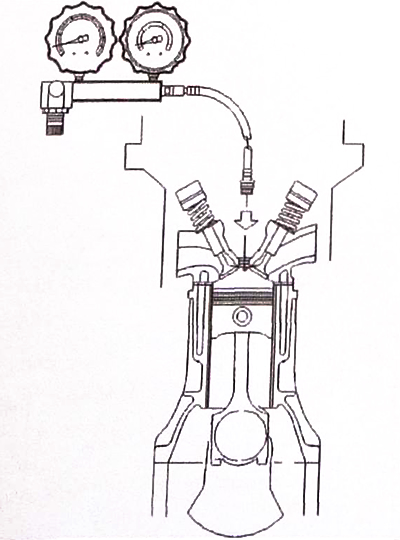

3. The measured air pressure is connected to the corresponding cylinder through an adapter installed in the spark plug / preheater recess.

4. The meter is used to determine the amount of leakage from the cylinder.

This is a pressure gauge with a regulator, it shows the amount of leakage expressed as a percentage, which allows you to determine the severity of any malfunction.

Troubleshooting

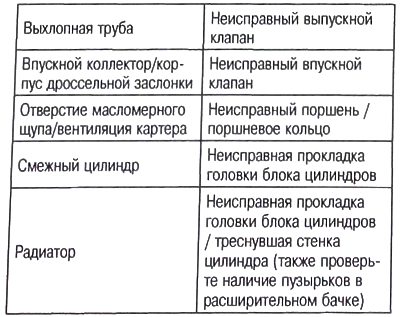

The source of the leak can be found by analyzing the sound at the following points.

A technical stethoscope or rubber hose can be used as listening aids.

Note. Leakage exists in piston rings even in a perfectly serviceable engine. This is the only place where a small leak is allowed.

If a leak is found that is suspected to come from the valve system, first check that the piston in the corresponding cylinder is at top dead center (TDC).

Then try to set the piston just before top dead center and check again.

The measurement results of repeated leak checks on the same engine tend to differ from each other.

This is due to changes in engine coolant temperature and the fact that the piston does not reach exactly the same position as in the previous check and depends on the amount of oil on the piston rings during the check.