Note. In this case, repair operations are shown for four-cylinder gasoline and diesel engines with a volume of 2.0 liters. Procedures for smaller engines are similar. For technical information on cylinder head components, see chapter «Data for adjusting and monitoring the mechanical part of petrol and diesel engines».

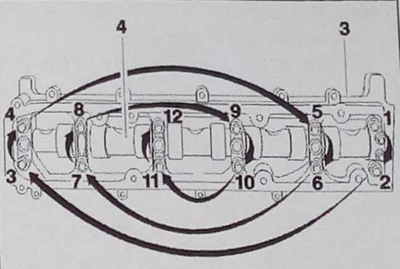

Loosen the mounting bolts one by one in the prescribed manner (see picture).

Remove:

- camshaft bearing housing (3);

- camshaft (4);

- distributor seal.

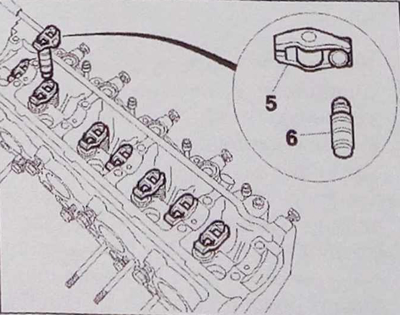

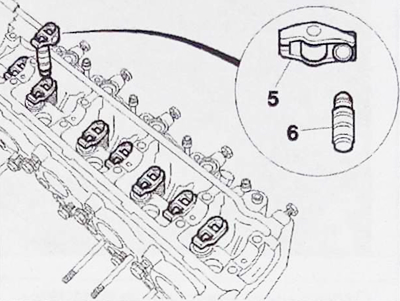

Remove by marking their position: roller rockers (5) and hydraulic pushers (6).

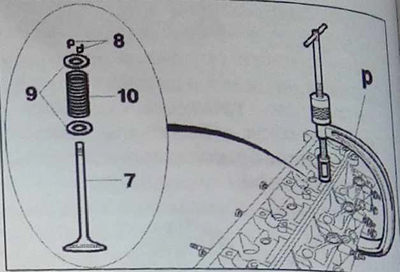

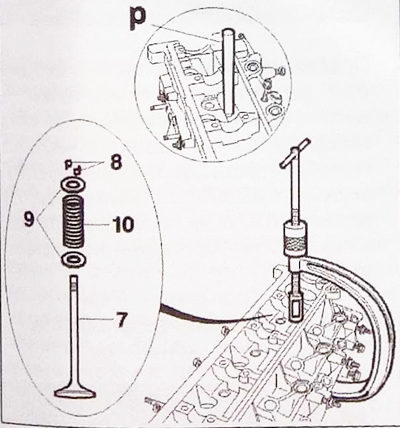

Remove with a drying tool:

- valves (7);

- crackers (8);

- support washers (9);

- springs (10).

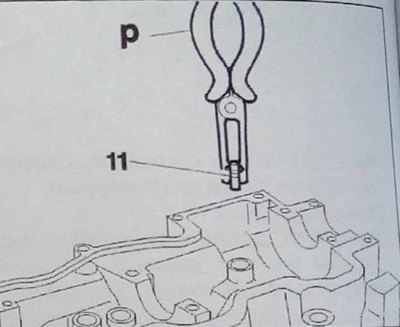

Remove oil seals (11), using forceps R.

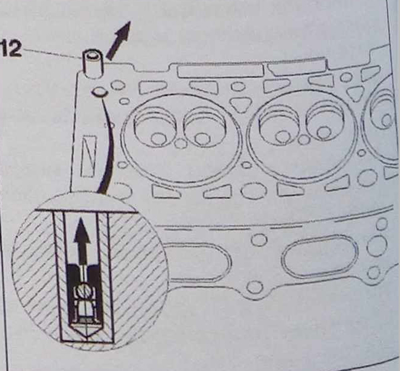

Remove check valve (12). Clean the sealing surfaces on the camshaft using a suitable cleaner.

Attention. For cleaning, do not use abrasive or piercing tools and tools. The surfaces to be joined must not show signs of impact or cracks.

Assembly

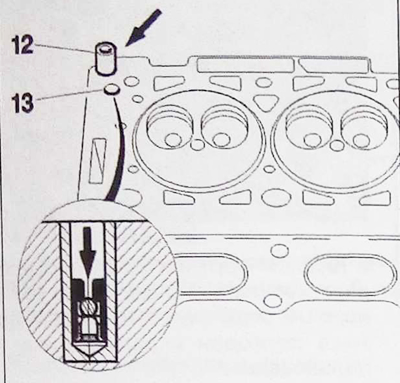

Install a new valve (12) into the channel (13).

Attention. Make sure the check valve is installed in the correct direction.

Fit new valve stem seals using tool P.

Install in place:

- valve (7) (lubricate the valve stem);

- support washers (9);

- springs (10);

- crackers (8).

Attention. Avoid touching the contact tracks of the rollers with your hands. Apply a thin layer of engine oil to the rollers and check them for sticking when rotating.

Reinstall pushers:

- lubricate the pusher housings;

- roller rockers (5) and hydraulic pushers (6);

- make sure the pushrods rotate freely in the cylinder head.

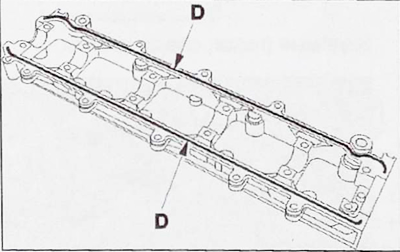

Apply sealant to the area (D) along the entire perimeter of the surfaces under the gaskets.

Note. Install the camshaft into the bearing housing.

Tighten, then alternately tighten the mounting bolts in the prescribed order.

Before installing the camshaft oil seal, first check that there are no sealant residues in its seat.

Pack grease into the space between the lips of the oil seal.

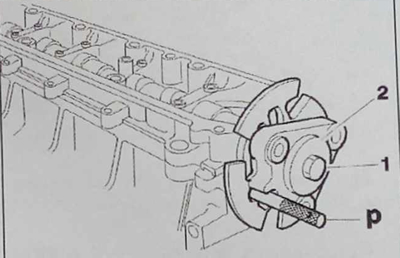

Camshaft seal installation procedure (see related description).

Install a new oil seal.

Install the camshaft flange.