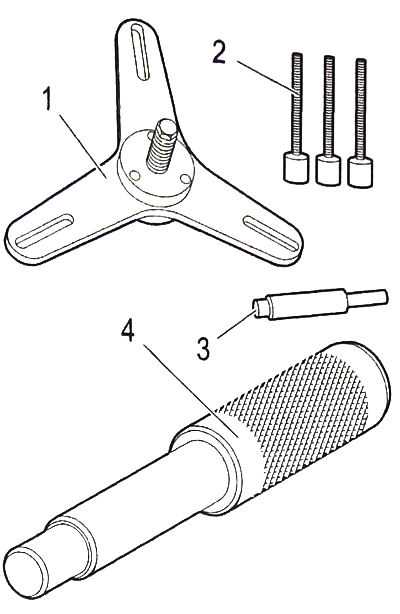

Clutch release tools

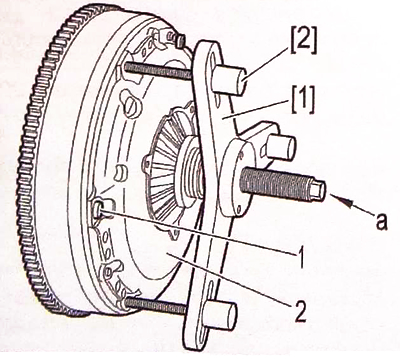

Clutch compression tool 0217:

1 - clutch mechanism compressor 0217.A;

2 - holding rod (diameter 8 mm) 0217.B2;

3 - rod for centering clutch 0217. C1.

4 - mandrel for centering the clutch disc.

- manual transmission type MA5 - pin for centering the clutch 9513-TV;

- BE4 type manual transmission - 9513-TV clutch centering rod.

Removing

Remove the gearbox (see corresponding operation).

Note. Mark the position of the clutch mechanism with wear determination in relation to the dual flywheel of the engine with vibration damper (DVA).

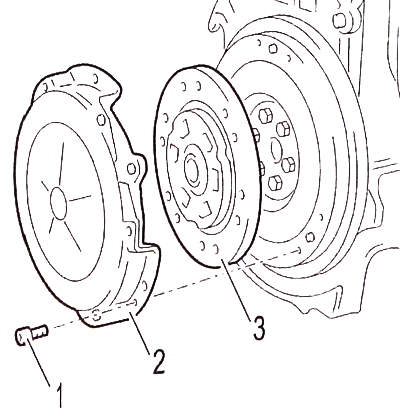

Loosen the bolts (1) and remove the clutch (2) and clutch disc (3).

Installation

Attention. If traces of oil are found in the clutch mechanism, perform the necessary operations to eliminate the oil leak.

Visually check:

- absence of impact marks and cracks on the engine flywheel holder;

- engine flywheel wear;

- condition of the starter ring gear;

- clutch mechanism.

If there is oil in the clutch mechanism, replace:

- crankshaft seal;

- clutch thrust bearing guide.

Attention. Do not reuse a clutch disc whose hub has signs of oxidation.

Standard clutch mechanism

Install the clutch disc (3) and clutch mechanism (2).

Center the clutch friction disc using tool 4.

Tighten the bolts (1) torque 20±2 Nm.

New clutch mechanism with automatic wear compensation system

Attention. Mechanism and clutch disc initially «paired», and cannot be replaced individually.

Remove the clutch disc (3).

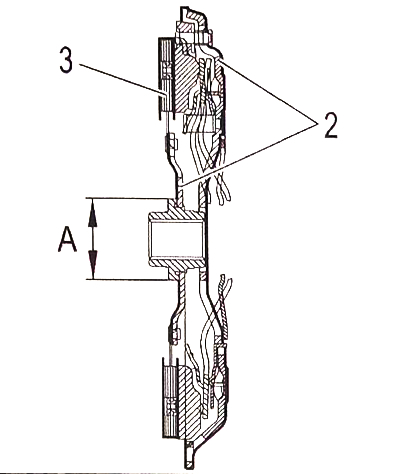

Attention. Use a larger diameter «A» clutch disc hub facing the engine flywheel.

Center clutch disc (3) with tool 3.

Installing the clutch mechanism

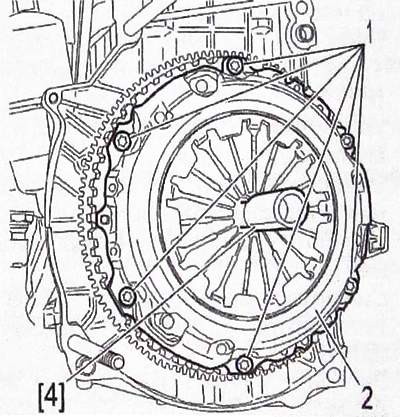

Install tools 1 and 2 on the clutch mechanism.

Screw the three retaining rods 2 in place of the bolts (1).

screw in the bolt «A» tool 1 to compress the clutch mechanism (2).

Install bolts (1) and tighten to 20±2 Nm.

Remove the bolt «A» tool 1 for a few turns to loosen clutch mechanism compression (2).

Remove tools 1, 2 and 3.

Install the remaining bolts (1).

Tighten the bolts (1) torque 20±2 Nm.

Reusable clutch mechanism with automatic clearance compensation device

Zeroing the automatic clutch clearance system.

Attention. The clearance is eliminated without the clutch disc.

Install the clutch mechanism (2) without clutch disc (3).

Install tools 1 and 2 on the clutch mechanism.

Screw the three retaining rods 2 in place of the bolts (1).

screw in the bolt «A» tool 1 to compress the clutch mechanism (2).

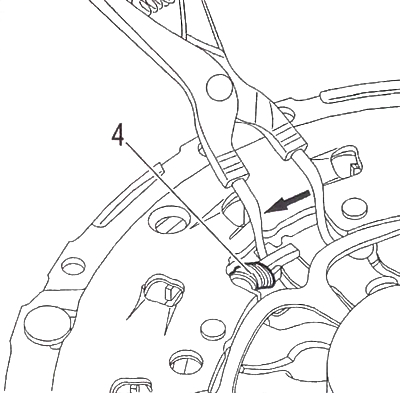

Compress the three backlash compensation springs (4) using pliers with circlips or a screwdriver (as shown by the arrow).

Note. Hold the gap selector springs compressed and remove the bolt «A» tool 1 for a few turns to unload the clutch mechanism (2). Clearance compensation springs (4) should remain compressed.

Remove the bolt «A» tool 1 for a few turns to loosen clutch mechanism compression (2).

Remove tools 1 and 2 and the clutch mechanism.

Install clutch mechanism and disc (follow the procedure «installation of a new clutch mechanism with an automatic gap selection device»).

Replace (on the gearbox):

- release bearing guide;

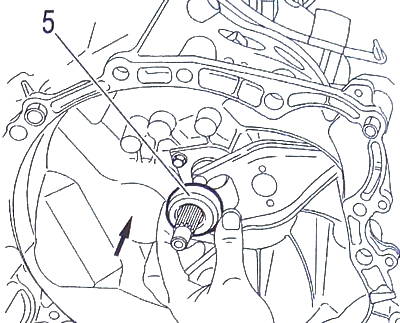

- clutch release bearing (5).

Installation of the release bearing on the guide is carried out as described below.

Connect the bearing to the lugs of the fork.

Install the release bearing with the fork on the guide (as shown by the arrow).

Lock the fork in the rearmost position with a rubber cord.

Spray some lubricant «MOLYCOTE RAPID PLUS» (aerosol) on the splines of the input shaft and on the guide with the limiter. Install the gearbox (see corresponding operation). Perform the initialization of the amount of engine torque transmitted to the clutch.