Brake discs

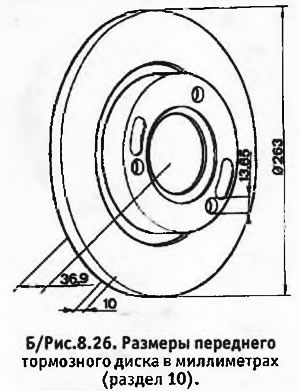

2. Inspect the disc for damage that may require replacement. With severe disc corrosion, cracks, deep grooves, etc. the only way out is to replace the disk. If the inspection showed that the disk is in good condition, measure its thickness in a number of places using a micrometer. The minimum admissible thickness of a disk after regrinding is specified in Specifications. The thickness of the disc must allow regrinding, after which the disc can continue to be used until its thickness is reduced to the minimum allowable (see specs), after which it must be replaced regardless of their condition. When grinding, the same layer of metal must be removed from both sides of the disc. Control dimensions for the disk, see B / fig. 8.26 and 8.27 and in the Specifications. You can remove the disc only after removing the hub. Because this requires special tools, it is better to entrust this work to a specialist (Additional information see chapter 7, section 4).

|  |

Brake drums

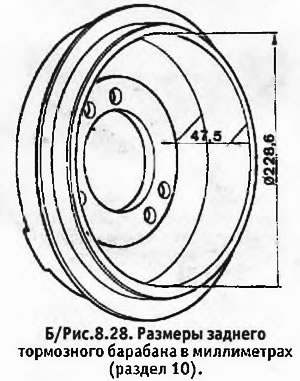

3. As with brake discs, brake drums should first be inspected for damage that may require replacement (severe corrosion, cracks, deep furrows, etc.). The difference between the largest and smallest diameters of the drum characterizes its ovality, which should not exceed the allowable limits. The maximum diameter to which the drum can be ground is specified in Specifications. Keep in mind that for drums standing on the same axis, the difference between the inner diameters after regrinding should not exceed 0.15 mm. Control dimensions for the brake drum, see B / fig. 8.29.

|  |