2. In emergency cases, you can adjust the headlights yourself using the adjusting screws provided on them. At the top of the headlight in the center is a screw for vertical adjustment of the light beam (see photo), and in its lower corner there is a horizontal adjustment knob (access through the engine compartment). Adjust the light beams so that when the dipped beam is switched on, the headlights shine straight ahead and slightly below the horizontal. Have the headlights adjusted by a specialist as soon as possible.

|  |

3. Means are provided to further lower the light beams when the machine is heavily loaded. In a heavily loaded car, the back settles, which leads to the fact that even when the dipped beam is turned on, the headlights shine upwards, blinding oncoming drivers. In order to adjust the headlights in this case, there is a rocker lever behind the mounting clip of each headlight. Pushing down the right side of the lever (when viewed from the driver's side) the headlight is in the position corresponding to the normal load of the machine. When the left side of the lever is pressed down, the headlight turns down slightly, which corresponds to the case of a heavy load of the machine (see photo).

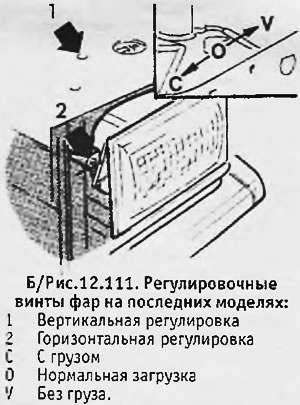

Headlight adjustment on production models since 1983

1. The location of the adjusting screws is shown in B / fig. 12.111.

2. On all recent models, except those with remote headlight adjustment, there is a load balancer at the rear of each headlight. Compensator center position ("0") corresponds to the case of an average load of the machine, the position "V" - the case of low load, and the position "WITH" - the case of a large load (lowering the headlights).