2. Loosen and remove the 2 solenoid through bolt nuts. Remove bolts and solenoid (the anchor will remain in the starter). Remove the solenoid spring (see pictures).

|  |

3. The horizontal plastic pin on which the solenoid lever rotates is eccentrically mounted, which allows you to adjust the depth of engagement of the starter gear with the ring gear. It is important to maintain the position of this finger when assembling the starter. Carefully mark the position of the pin head relative to the adjacent surface, knock out the central metal pin and remove the plastic pin (see pictures).

|  |

4. Note that the starter motor is secured to the pinion side of the end cap with a mounting tab. Loosen and remove the 2 bolts securing the starter to the end cap. Remove the sealing piece between the end cap and the starter motor and carefully remove the end cap leaving the solenoid operated lever in engagement with the anchor ring. After that, remove the lever from the ring (see pictures).

|  |

|  |

5. Carefully remove the rubber boot from the brush holder plate protecting the end of the armature. Clamp the end of the armature shaft (gear side) in a vice with soft jaws and unscrew the bolt from the other end of the shaft (from the side of the brushes). This bolt has a left hand thread. Pay attention to the washers and lock plate under the bolt head and note their relative position as when reassembling, they must be installed in the same sequence (see photo).

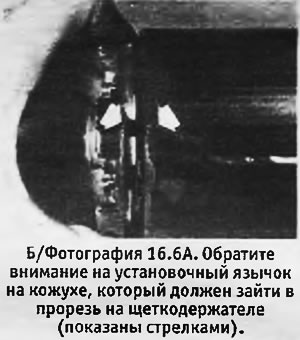

6. Pay attention to the fact that the brush holder is fixed on the motor casing with an installation tongue. Carefully remove the brush holder from the armature and pull it out of the casing. Pay attention to the relative position of the shim and the wave washers on the end of the armature shaft on the side of the brush holder. When reassembling, they must be installed in the original sequence. Do not attempt to detach the brush holder from the housing: it is held in place by the excitation wire.

|  |

7. Inspect the brushes for abrasion and check their length and fit in the brush holder (see photo). Clean them of dirt with a lint-free cloth soaked in gasoline. If the brushes get stuck in the brush holder, you can lightly file them with a fine file (at the same time, make sure that the landing of the brushes does not become too loose).

8. Pull the anchor out of the starter housing (see photo), clean it of dirt with a lint-free cloth soaked in gasoline, and inspect the switch electrodes. If they are covered with a shiny coating or dirty, carefully clean them with glass paper.

9. If there are deep grooves or sparks on the electrodes, or if the armature shaft is bent, the starter should be taken to a specialist for repair and possibly replacement.

10. The starter is assembled in the reverse order. It is imperative that the shims are installed in their original positions. Check that the mounting tabs fit correctly into the slots intended for them. The pivot pin of the solenoid lever must also be set to its original position.