The engine will not start

Engine does not start when starter is turned on

Low battery (charge battery, start "smoking" or "from the pusher".

Loose or corroded battery terminals.

bad "weight" battery (check ground wire).

bad "weight" engine (check tire "masses").

Loose contacts or damaged starter wiring (or solenoid).

The gearshift lever on the automatic transmission is incorrectly set or the ignition lock is faulty.

Faulty ignition/starter switch.

Serious mechanical failure (jammed engine) or affects the long downtime of the machine (piston rings corroded to the cylinders).

Internal starter or solenoid failure (see chapter 10).

Starter cranks engine too slowly

Partially discharged battery (recharge battery, start "smoking" or "from the pusher").

Loose or corroded battery terminals.

bad "weight" battery (check ground wire).

bad "weight" engine (check tire mounting "masses").

Loose starter wiring (or solenoid).

Internal starter fault (see chapter 10).

The starter turns but does not start the engine

The battery is discharged.

Starter gear stuck on clutch.

Damaged or worn flywheel teeth.

Loose starter mounting bolts.

Engine cranks normally but won't start

Damp or dirty high voltage wires and distributor cover (crank the engine over and check for spark. If not, try treating the wires and cover with a moisture dispersant such as Holts Wet Start.

The breaker contacts are oxidized or incorrectly adjusted.

Back suction or insufficient suction (cold engine).

Engine stalls and won't start again

The engine suddenly stalls - a malfunction of the ignition system

Loose or disconnected low voltage leads.

Damp or dirty high voltage wires or distributor cover (for example, after driving through a deep puddle).

Faulty ignition coil or capacitor (check for spark).

Check ignition system faults (see chapter 4).

The engine stutters and then stalls - fuel system malfunction

There is no fuel in the tank.

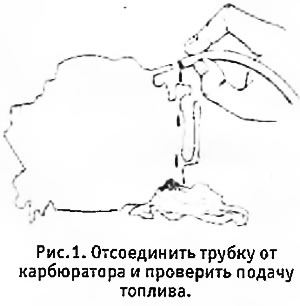

Faulty fuel pump or clogged fuel filter (check fuel supply).

The air vent of the fuel tank filler neck is clogged (suction is felt when the cap is removed from the fuel tank).

Carburetor needle valve stuck.

Clogged carburetor jets (dirty fuel).

Other fuel system malfunctions (see chapter 3).

Engine stalls - other causes

Severe engine overheating.

Serious mechanical failure (for example, the camshaft drive has failed).

The engine gets very hot

Loose or broken drive belt (see photo) - tighten or loosen the belt (see chapter 2).

Loss of coolant due to internal or external leakage (see chapter 2).

Faulty thermostat.

Low oil level.

Seizes the brakes.

Internal or external clogging of the radiator.

The electric fan is not working well.

Clogged channels in the water jacket of the engine.

The ignition timing is set incorrectly or the automatic ignition advance does not work.

Too lean mixture.

NOTE: Do not add cold water to an overheated engine as this may damage it.

Low oil pressure

Gauge shows low oil pressure or warning light comes on when engine is running

Low oil level or wrong oil.

Faulty oil pressure sensor or gauge.

The wire leading to the pressure sensor is caught on "mass".

The engine has overheated.

Clogged fuel filter or faulty bypass valve. Oil pressure relief valve defective.

Clogged oil strainer.

Worn oil pump or loose fittings.

Worn main or connecting rod bearings.

NOTE: Low idle oil pressure on an older engine is not necessarily a cause for concern. It is much more dangerous when the oil pressure drops sharply while driving. In any case, the pressure sensor should be checked first.

Noises in the engine

Preignition (detonation) when you press the gas pedal

Incorrect fuel octane rating.

Ignition timing incorrectly adjusted.

Worn or defective distributor.

Worn or poorly adjusted carburetor.

Excessive accumulation of soot in the engine.

Engine whistles or "squeals"

Leaking vacuum hose.

Air leaking into the carburetor or manifold gasket.

Broken cylinder head gasket.

Light knock or rumble in the engine

Valve clearances incorrectly adjusted.

Worn valve train.

Worn chain (or belt) camshaft.

Broken piston ring (ticking sound).

Heavy knocking or hitting

Unintended mechanical contact (e.g. fan blades).

Worn fan belt.

Peripheral hardware failure (generator, water pump, etc.).

Worn connecting rod bearings (strong uniform knock, may decrease with increasing engine load).

Worn main bearings (rumble and knock, may worsen with increasing engine load).

Pistons are knocking (most noticeable when the engine is cold).