Attention: the screws for regulating the maximum engine speed and intermediate pressure, as well as the plugs that close the inspection holes for regulating the injection timing, are closed and sealed by the manufacturer during assembly. If the machine is still under warranty, these seals cannot be removed. Do not attempt to adjust the timing of the pump unless you have sufficiently accurate gauges.

1. Disconnect the negative cable from the battery.

2. Cover the generator with a plastic bag to protect it from fuel splashes.

3. Engage the handbrake and jack up the front right wheel of the machine until it is off the ground. Support the car and engage 4th or 5th gear. This will allow the engine to be turned using the right front wheel.

4. Disconnect the wire from the glow plug of cylinder No. 4 (from the timing belt side) and turn out the spark plug. Keep in mind that the injection timing is adjusted with piston No. 4 in the TDC position. on the compression stroke (those. piston No. 1 is in the T.M.T. with valves changing their position).

5. You will need 2 dial gauges to check the position of the No. 4 piston and injection pump. You will also need magnetic tripods or brackets to mount the instruments in the right places on the engine.

6. Unscrew and remove the plug on the cylinder head next to the nozzle No. 4 (see photo).

7. Turn the engine forward so that pressure is felt in cylinder No. 4, indicating that piston No. 4 begins to rise on the compression stroke.

8. Install the dial gauge over the inspection hole and attach its probe to the piston (see photo).

9. Turn the engine further forward so that the instrument shows the maximum piston lift No. 4. To check, rotate the engine back and forth a little so as to exactly reach the top position of the piston, and set the instrument to zero.

10. Loosen the bottom of the two large side plugs on the injection pump. Place a small container under the plug, then remove the plug and collect the spilled fuel in a container (see photo).

11. Under the stopper there is a guide for the probe of the dial instrument. Insert the tester and connect it to a dial gauge positioned exactly above the hole (see photo and D/fig. 3.9). Keep in mind that the probe must have a pointed end so that it fits completely into the groove on the pump rotor.

|  |

12. Turn the engine back about 1/8 of a turn or so that the No. 4 piston moves 4.0 mm down the cylinder. Now slowly turn it forward, following the readings of the dial gauge on the injection pump. After the probe reaches the bottom of the groove on the rotor, and then rises by 0.01-0.02 mm, check that the upper dial gauge shows 2.26±0.05 mm b.m.t. If other indications are obtained, do the following.

13. Check the accuracy of zeroing the upper dial gauge by repeating the procedure in paragraph 9.

14. Turn the engine back about 1/8 of a turn or so that the No. 4 piston moves 4.0 mm down the cylinder. Now slowly turn it forward so that the piston No. 4 is in position 2.26±0.05 mm to TDC.

15. To turn out nuts of unions and to disconnect from TNVD fuel tubes of atomizers. Loosen the fixing nuts and bolts of the injection pump.

16. Rotate the pump housing so that the probe is at the bottom of the groove on the pump rotor. Set the dial gauge to zero and turn the pump clockwise (when viewed from the side of the fuel injector tubes) so that the probe rises by 0.02 mm.

17. Tighten the pump mounting nuts and bolts, making sure that the dial gauge shows no movement.

18. Check the pump timing again as indicated in paragraph 12.

19. Remove the dial gauges and replace the plugs. Connect the fuel pipes of the injectors and tighten the union nuts.

20. Replace the glow plug and connect the wire to it.

21. Lower the machine to the ground and connect the negative cable to the battery. Remove the plastic bag from the generator.

22. Pump fuel into the system (see section 17).

Injection pump (latest Lucas CAV/Roto-Diesel models)

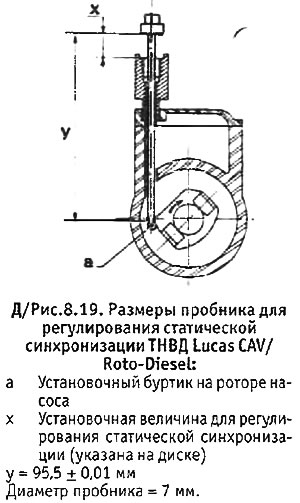

1. Since 1987, modified injection pumps have been gradually installed. The new type of pump can be recognized by the white plastic disk on the front surface, which shows the value for adjusting the static timing of the pump (see photo). The blue disc indicates that this pump has been factory refurbished. The setting value for adjusting the pump may also be indicated on a plastic plate attached to the pump control lever.

2. The new type of pump is adjustable in the TDC position. Only one dial instrument is needed, however, you will have to make a device in the form of a curved rod yourself, which will be inserted into the hole for installing the TDC. For these purposes, we used an M8 bolt, the thread of which was removed with a file attached to the welding electrode (see photo). Alternatively, with the starter removed, you can use a drill or a straight bar (see d/photo 22.26).

3. Prepare for work as described above in paragraphs 1-3.

4. Turn the engine so that the piston N 4 (from the timing belt side) stood in the v.m.t. on the compression stroke. In order to verify this, remove the glow plug of the No. 4 cylinder or the plug of the hole for installing the TDC, located next to the nozzle No. 4 (see d/photo 6.85) and make sure that the pressure builds up in the cylinder. Alternatively, you can remove the valve cover and set the moment when the valves of cylinder No. 1 begin to change their position (the intake valve will open and the exhaust valve will close).

5. Insert the fixture for the installation of the w.m.t. into the hole in the left end of the cylinder block (behind the starter). Turn the engine back and forth slightly so that the tool fits into the hole in the flywheel, and leave it in this position.

6. Remove the plug from the inspection hole on the top of the pump. Position the dial gauge so that it indicates the movement of the probe inserted into this hole. To fix the magnetic stand of the dial gauge in place, you can use a steel plate bolted to the engine mount or a valve cover (see pictures).

7. Make a probe according to the dimensions indicated in D / fig. 8.19. Insert the probe into the inspection hole so that its end is on the mounting shoulder on the pump rotor and turn the dial gauge so that you can take its readings.

8. Pull out the tool for installing the V.M.T. and turn the motor about 1/4 turn back. In this position, set the dial gauge to zero.

9. Slowly turn the engine forward until the TDC installer can be inserted again. View the readings of the dial gauge: it should give the value indicated on the pump disk (±0.04 mm).

10. If the device does not give the desired value, do the following.

11. Disconnect the fuel tubes of the injectors from the pump. Loosen the fixing nuts and bolts of the pump and turn its body away from the engine. Set the dial gauge to zero.

12. With the engine still in the TDC position, slowly turn the pump back toward the engine until the dial gauge shows the value indicated on the dial. In this position, tighten the fixing nuts and bolts of the pump. Remove the device for installing the w.m.t. and check pump timing as described above.

13. Upon completion of the adjustment, reconnect the fuel pipes of the Injectors, remove the dial gauge and the device for setting the w.m.t. reinstall the inspection hole plug.

14. Replace other removed and disconnected parts, remove the plastic bag from the generator and lower the machine to the ground.

Lucas Roto- or Con-Diesel injection pump on 405 models

1. The procedure is the same as previously described for the latest Lucas CAV/Roto-Kesel injection pumps.

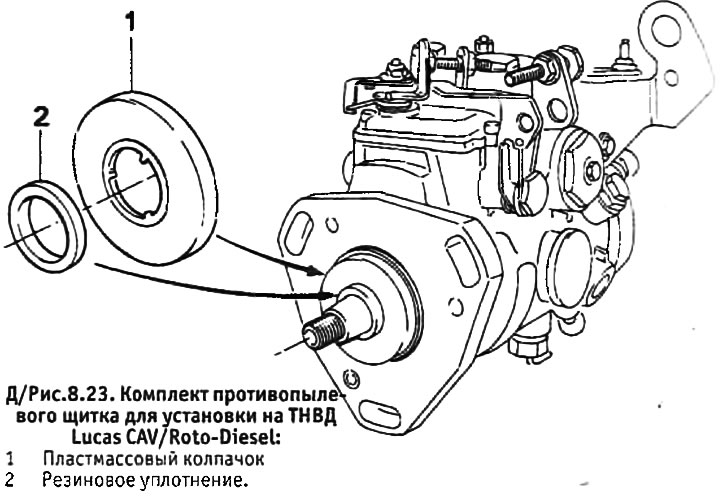

Anti-dust guard of high-pressure fuel pump Lucas CAV/Roto-Diesel

1. Beginning in April 1988, the Lucas CAV/Roto-Diesel injection pump is fitted with a dust shield to protect the front bearing seal.

2. If for some reason you are going to remove the old pump, you should purchase a dust shield, which is sold in a special kit, and install the pump with a dust shield.