2. Remove the oil pump (see section 14).

3. If there is a wear protrusion on the top of the cylinders, it must be removed with a scraper or special tool in order not to damage the pistons during removal. In principle, the presence of such a protrusion may indicate the need for reboring the cylinders, which inevitably requires new pistons.

4. Check that there are marks on the connecting rods and connecting rod caps indicating their position. If there are no marks, apply them yourself using a center punch on the side of the oil filter (connecting rod #1 closest to flywheel).

5. Turn the crankshaft so that the pistons NN 1 and 4 are in the n.m.t. Remove the nuts on the No. 1 connecting rod cap, remove the cap and pull out the lower half of the connecting rod bearing shell (see photo).

6. Pull the piston out of the cylinder with a hammer handle and remove it from the block, temporarily install the bearing shell and connecting rod cover in place and fasten them with nuts so that they are not lost.

7. Remove the No. 4 piston in the same way and then rotate the crankshaft 180°in order to convert to n.m.t. pistons NN 2 and 3. Remove these pistons.

8. If you want to install new piston rings in old cylinders, you should clean the cylinder walls from lacquer so that the piston rings rub well. Wrap the connecting rod journals with duct tape to protect them and sand the cylinder walls in a crosswise motion. A honing head can be used to process the cylinder walls. At the end of processing, wash off traces of abrasive material and remove the protective tape from the connecting rod journals.

9. Lay out the pistons with connecting rods in order along with their liners, connecting rod caps and nuts.

10. Place the piston rings so that their locks are offset by 120°relative to each other.

11. Clean the bearing shells, caps and connecting rods and install the shells in place so that the mounting tabs on them fit into the grooves intended for them.

12. Lubricate the cylinder walls, connecting rod journals and liners with oil. Install the piston ring compressor on piston No. 1. With connecting rod journals No. 1 and 4 in the N.D.M. Insert the No. 1 piston into the cylinder closest to the flywheel, making sure that the cloverleaf cutout on the piston crown is on the oil filter side.

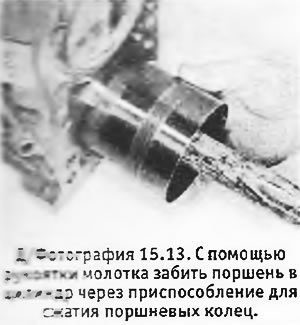

13. Using a hammer handle, drive the piston into the cylinder through the piston ring compressor (see photo). Bring the connecting rod to the crankpin and install the cap in place of the bearing shell, making sure it fits correctly.

14. Install the nuts and tighten them to the correct torque (see photo). Rotate the crankshaft and check for freedom of rotation.

15. Repeat the above procedure for the remaining three pistons.

16. Install the oil pump (see section 14).

17. Install the cylinder head.