2. Remove the engine mudguard under the right front wheel arch. To create more space to work, drain the cooling system (see chapter 2) and disconnect the lower radiator hose from the water pump inlet.

3. Disconnect the negative cable from the battery.

4. If necessary, remove the timing belt from the injection pump sprocket and turn the engine 1/4 turn in either direction. In this case, all pistons will go down to half the cylinders.

19. Remove the bolts securing the exhaust downpipe to the exhaust manifold. Disconnect the pipe and remove the springs and rings.

20. Gradually turn out the cylinder head bolts in the reverse order to that shown in D / fig. 1.9. Remove bolts and washers.

21. Rock the cylinder head to disengage it from the cylinder block and dowel pin. Tool used for this "Peugeot" consists of two metal rods with ends bent at right angles (see d/fig. 1.7).

22. Remove the cylinder head from the block. Remove its gasket.

23. Don't throw away your old gasket until you get a new one. The correct gasket thickness is calculated after determining the protrusion of the pistons in the TDC position.

24. Clean the contact surfaces of the block and cylinder head from traces of the old gasket (best with a blunt tool made of soft material so as not to damage the surface). Clean the threads of the cylinder head bolts and the bolt holes in the cylinder block.

25. Check that the timing belt has been removed from the injection pump sprocket and rotate the engine so that the pistons NN 1 and 4 are in the top dead center position. Install the dial gauge on the cylinder block and bring it to zero on the surface of the block. Move the probe of the device to the center of piston No. 1 and slowly turn the crankshaft back and forth so that the piston moves from the top dead center position. Record the maximum piston protrusion that the gauge will show (see photo).

26. Repeat the above procedure on piston No. 4, then turn the crankshaft half a turn (180°) and take measurements on pistons NN 2 and 3.

27. If you don't have a dial gauge, piston protrusion can be measured using a ruler and feeler gauges or a vernier caliper, but these methods are less accurate.

28. Determine the maximum piston protrusion and use it to determine the correct gasket thickness from the following table:

| Piston protrusion | Gasket marking |

| 0.54-0.65mm | 1 notch or 1 hole (only for factory installation - when replacing, choose a gasket of the next class of thickness) |

| 0.65-0.77 mm | 2 notches or 2 holes |

| 0.77-0.82mm | 3 notches or 3 holes |

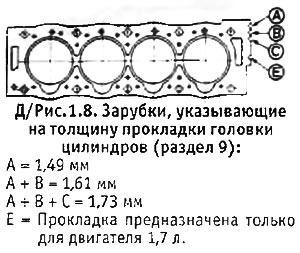

Note that the notch or hole in the gasket axle (see d/fig. 1.8) only serve to indicate that the gasket is for 1.7L engines only (XUD 7) and have nothing to do with the thickness of the pad.

29. Turn the crankshaft clockwise (viewed from the timing belt side) so that pistons NN 1 and 4 pass through the n.m.t. and rose to the middle of their cylinders. Pistons NN 2 and 3 will also stand in the middle of their cylinders, however, in the lowering phase.

30. Install a gasket of the required thickness on the block so that the identification notches or holes are on the side of the flywheel (see photo). Check that the dowel pin is in place on the block (from the timing belt side).

Models up to September 1986

Note: Before tightening the cylinder head bolts, read the notes at the beginning of this section to make sure your engine has the old style bolts. If not, go to paragraph 33.

31. Lower the cylinder head onto the block.

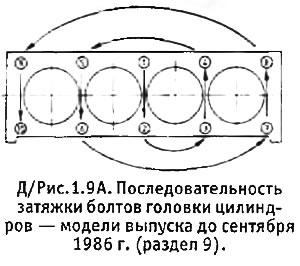

32. Apply lubricant to the threads and contact surfaces of the bolts, insert them together with washers (convex side up) and tighten in the sequence shown in D / fig. 1.9A, in three steps (see Specifications).

Models since September 1986

Note: Before tightening the cylinder head bolts, read the notes at the beginning of this section to make sure your engine has the new type of bolts. If not, go back to paragraph 31.

33. Thoroughly clean the bolt holes in the cylinder head with a suitable tap (M12x1.5).

34. Lower the cylinder head onto the block.

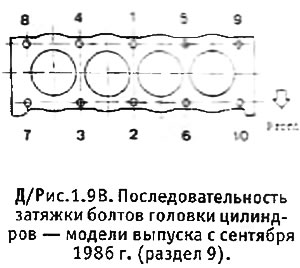

35. Lubricate the threads and contact surfaces of the new bolts and install new washers. Insert the bolts and tighten them in the sequence shown in D / fig. 1.9V, three steps (see specs).

All models

36. Check valve clearances (see section) and adjust them as necessary. This must be done even if you adjusted the clearances with the cylinder head removed, because. after installing it, they may change slightly.

37. Lubricate the contact surfaces of the exhaust manifold and exhaust system downpipe with high temperature grease, connect the pipe to the manifold, and install the bolts along with their springs, rings, and self-locking nuts. On 1.9 liter engines, the bolts have a shoulder to ensure proper spring compression. On 1.7 liter engines, gradually tighten the bolt nuts so that approximately 4 threads are exposed on each bolt, and the springs are compressed to 23.5 mm in length.

38. Check that the segment key is in place on the camshaft and then install the sprocket and its bolt. Tighten the bolt to the desired torque while holding the camshaft with a wrench thrown over a special ledge between 3 and 4 cams.

39. Rotate the camshaft so that the tops of cams 4 and 6 (counting from the flywheel) looked down.

40. Rotate the crankshaft 1/4 turn clockwise so that pistons 1 and 4 are in TDC, and insert a rod into the flywheel to set the TDC position. Do not turn the crankshaft counterclockwise, as in this case, the pistons NN 2 and 3 will pass through the TDC. and hit valves NN 4 and 6.

41. Align the holes and install the M8 bolt on the camshaft sprocket.

42. Install the valve cover with a new gasket.

43. Apply threadlocker to the threads of the bolts and then insert and tighten one of the top bolts on the right engine support bracket. Install and tighten tensioner adjusting bolt. Loosen tensioner pivot nut.

44. Install the timing belt and adjust its tension (see section 4, paragraphs 20-25).

45. Connect the bypass fuel pipe to the injection pump.

46. Connect the wires to the glow plugs.

47. Install the left engine lift bracket.

48. Connect the fuel pipes to the injectors and tighten the union nuts.

49. Connect the crankcase ventilation hose to the valve cover. Connect wiring to diagnostic socket or oil level sensor.

50. Install the brake booster vacuum pump (see chapter 8). Where applicable, install the power steering pump drive belt and adjust its tension.

51. Connect the intake air hose to the intake manifold.

52. Install the oil filler plug/breather.

53. Clean the contact surfaces of the thermostat housing, install it with a new gasket and tighten the mounting bolts. Install 2 small hoses.

54. Connect the heater hose to the cylinder head.

55. Install the sections of the casing of the gas distribution mechanism.

56. Install the right engine support bracket and tighten the fixing nuts. Disconnect the hoist from the engine or pull out the jack.

57. Install the air cleaner (see chapter 3).

58. Connect the negative wire to the battery.

59. Pour liquid into the cooling system (see chapter 2).

60. Lower the car to the ground.

Pre-September 1986 release models only.

61. Start the engine and let it run for 10 minutes at 3000 rpm, then turn on the ignition and let the engine cool down for at least 2 hours.

62. Remove the cap of the expansion tank of the cooling system in order to relieve pressure from the system, and then reinstall the cap.

63. Alternately, working in the correct sequence, loosen each cylinder head bolt 90°, and then tighten the bolts to the final torque specified in Specifications (see photo).

Cylinder head (XUD7T engine) - removal and installation

3. Follow the above instructions, however, before removing the cylinder head, disconnect the following additional parts:

- A. Turbocharger supply and return fuel pipes.

- b. Hose connecting the intake manifold to the injection pump (see photo).

- V. fuel heater (if installed).

- d. The turbocharger itself can be removed along with the manifolds.

3. After installing the cylinder head and before the first start of the engine, fill the turbocharger lubrication circuit by disconnecting the cut-off solenoid wire from the fuel pump and turning the engine with the starter 3 times (10 sec each time).

Head Gasket Identification - All Models

4. In addition to the three gasket thicknesses above, you may encounter a gasket marked with 4 notches or 4 holes. This gasket is installed on remanufactured engines where the pistons protrude more than 0.84 mm above the cylinder block.

5. The cylinder head gasket on the XUD7T engine has 2 notches on the center shaft ("E" on D / fig. 1.8). The thickness of this gasket is still determined by the number of notches in its corner.

Cylinder head and exhaust manifold (XUD7T/XUD7TE engines) - modification

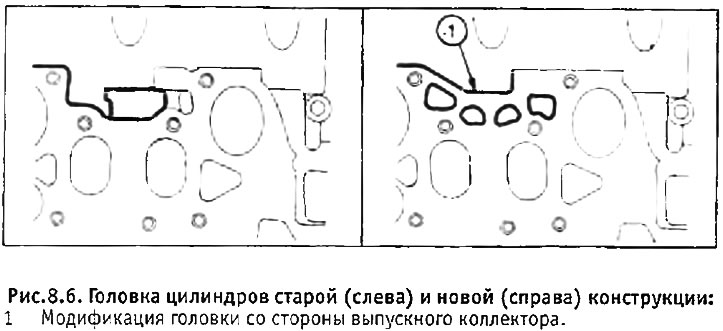

1. Since January 1991 (identification number 70250000) All XUD7T/XUD7TE engines are equipped with a modified cylinder head, reinforced in the area of the water jacket channels. It should be noted that the modified cylinder head was supplied for replacement by specialized centers "Peugeot" and before this date.

2. Differences between old and new cylinder heads are shown in fig. 8.6.

3. A new cylinder head must be installed with a new exhaust manifold and gasket. The new exhaust manifold can be identified by 4 individual ports instead of the two of the earlier manifolds.

4. If you are experiencing coolant leakage on early models, it may be caused by a leaky exhaust manifold side cylinder head gasket. You can fix this problem by installing a new cylinder head with a new exhaust manifold and gaskets.