2. The timing belt should be replaced every 75,000 km, however, if it is oily or noisy during operation (scraping sound caused by uneven belt wear), the belt must be replaced without waiting for the planned period. On Bosch high pressure pump models, excessive play in the front bearing can wear out the sidewalls of the belt.

3. Engage the handbrake and jack up the right front corner of the machine so that the wheel is just off the ground. Support the car and engage 4th or 5th gear. This will allow the crankshaft to be rotated by turning the right wheel.

4. Remove the engine mudguard under the right front wheel arch. To create more space to work, drain the cooling system (see chapter 2) and disconnect the lower radiator hose from the water pump inlet.

5. Disconnect the negative cable from the battery.

6. Loosen the alternator pivot bolt and its adjusting bolts and then unscrew the tension bolt so that the drive belt can be removed from the pulleys.

7. With 4th or 5th gear engaged, ask an assistant to depress the brake pedal and remove the crankshaft pulley bolt. Alternatively, you can block the crankshaft by unscrewing the bolts securing the gearbox cover, removing the cover and inserting a wide screwdriver into the starter ring gear.

8. Remove the pulley from the front end of the crankshaft.

9. Unscrew the bolts securing the lower casing of the gas distribution mechanism.

10. Suspend the engine on a hoist or support it with a garage jack.

11. Remove nuts and remove right engine support bracket.

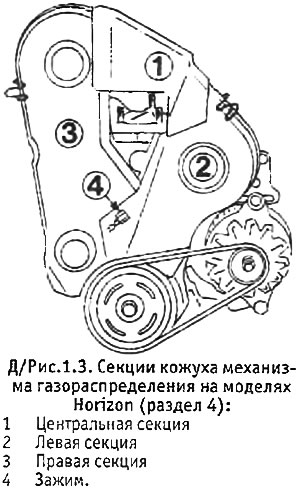

12. Pull up the front clip, loosen the spring clips and remove from the timing case section (see pictures).

|  |

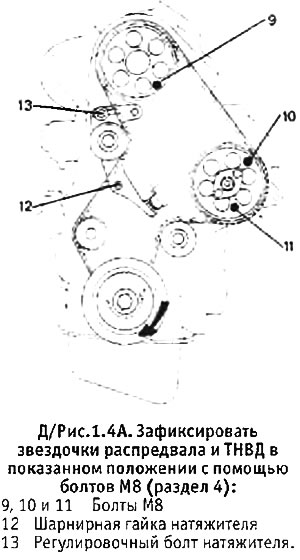

13. Turn the engine using the right front wheel so that the bolt holes in the camshaft sprockets and injection pump align with the corresponding holes in the engine front plate.

14. Insert a metal bar with a diameter of 8.0 mm into a special hole in the left rear flange of the cylinder block next to the starter and then carefully turn the engine in any direction so that the bar enters the hole on the flywheel intended for installation of the high-pressure motor. (see d/photo 22.26).

15. Insert 3 M8 bolts into the holes on the camshaft sprockets and injection pump and manually screw these bolts into the engine front plate (see d/fig. 1.4A).

16. Loosen the pivot nut and adjusting bolt of the timing belt tensioner and turn the bracket counterclockwise to relieve tension on the timing belt. Tighten the adjusting bolt again to lock the tensioner in the released position.

17. Draw an arrow on the timing belt to show its normal direction of rotation, and remove it from the camshaft sprockets, injection pump, water pump and crankshaft.

13. Inspect the belt for cracks, abrasion and damaged teeth. Pay special attention to the base of the teeth. If there is damage or if the belt is oily, it must be replaced (after localizing and eliminating the source of oil leakage).

19. Start installing the belt by putting it on the crankshaft sprocket. Check that the arrow drawn on the belt points in the correct direction.

20. Holding the belt on the crankshaft sprocket, put it on the roller and then on the injection pump sprockets, camshaft and water pump, as well as on the tensioner roller. In order for the belt to fit correctly, install it on the injection pump sprocket only half the width, then put it on the camshaft sprocket, keeping the belt taut, and slide it all the way onto the crankshaft sprocket. After that, push the belt all the way over the remaining sprockets (see D/Photos 26.54A, 26.54B and 26.54C).

21. With the pivot nut loose, loosen the tensioner adjusting bolt while holding the bracket against spring pressure. Slowly release the bracket so that the roller is pressed against the timing belt. Tighten the adjusting screw again.

22. Remove the bolts from the camshaft sprockets and injection pump and pull the metal bar out of the cylinder block.

23. Rotate the motor 2 full turns in the normal direction of rotation. Do not turn the motor backwards as the timing belt ac.-women remain taut on the sprockets of the crankshaft, injection pump and camshaft.

24. Loosen the tensioner adjusting bolt so that the tensioner spring can press the roller against the timing belt, and then tighten the adjusting bolt and pivot nut.

25. Check valve timing (see paragraphs 13 and 14) and pull out the metal bar.

26. Reinstall the sections of the casing of the gas distribution mechanism and secure them with a special clip and spring clips. Install the lower timing cover and tighten its mounting bolts.

27. Install the right engine support bracket and tighten the fixing nuts.

28. Disconnect the lift from the engine or pull out the jack.

29. Put the pulley on the front end of the crankshaft.

30. Apply 3 drops of thread locking fluid to the threads of the crankshaft pulley bolt, insert the bolt and tighten it to the desired torque, keeping the crankshaft from rotating as described in paragraph 7.

31. Install the alternator drive belt and tighten it as described in chapter 10.

32. Connect the negative wire to the battery.

33. Install the engine mudguard under the right front wheel arch.

34. Where applicable, connect the lower radiator hose and add fluid to the cooling system (see chapter 2).

35. Lower the car to the ground.

Modifications to the timing cover, timing belt tensioner and related parts - all models from 1988

1. Early 1988 (more precisely since September 1987.) small changes were made to the fasteners of the casing of the gas distribution mechanism. The fixing clip is no longer installed, the number of studs has been increased from one to two.

2. At the same time, changes were made to the tensioner pulley, injection pump sprocket and (only on models with Bosch pump) into the pump front bearing.

3. The old and new tensioner rollers are completely interchangeable. The rest of the parts are not interchangeable.

Timing belt - modification

1. Since the beginning of 1992, the timing belt has been made from an improved material known as "hydrogenated nitrile" (HSN). This material has increased resistance to oil and high temperatures.

2. Be aware that some older models may already have a new type of belt installed during maintenance.

3. If you purchase a new belt to replace the old one, it will inevitably be of the new type. This is confirmed by the letters HSN stamped on the inside of the belt.