Note: The oil seal replacement procedure described here applies to the engine standing on the machine. With the engine removed, skip the instructions regarding preparations to gain access to the oil seal. Camshaft oil seal (from the timing belt side).

1. Follow the instructions in paragraphs 1-12 section 5.

2. Remove the timing belt from the camshaft sprocket and tie it to the side, making sure not to kink.

3. Unscrew the M8 bolt holding the camshaft sprocket in the position corresponding to the desired valve timing.

4. Fix the sprocket with a suitable tool inserted into two of the holes in the sprocket (see d/fig. 1.11). Such a tool can be made independently from a metal plate and two long bolts. Alternatively, you can fix the sprocket with a belt wrench used to remove the oil filter.

5. Remove the sprocket bolt and remove it from the camshaft. Be careful not to rotate the camshaft as this will cause the pistons to hit the valves in cylinders NN 1 and 4. Remove the key if it is loose.

6. Pull out the old oil seal using a suitable hook.

7. Clean the nest.

9. Install the key on the camshaft (if filmed) and sprocket, insert the bot and tighten it, keeping the camshaft from rotating.

10. Install the M8 set bolt on the sprocket.

11. Put on and adjust the timing belt (see section 4, paragraphs 20-25). The remaining operations are performed in reverse order.

Camshaft oil seal (flywheel side)

12. Remove the air cleaner.

13. If necessary, remove the air inlet.

14. Loosen the pivot and adjusting bolts of the brake booster vacuum pump, turn the pump forward and remove the drive belt from the pulleys. Where applicable, also remove the power steering pump drive belt.

15. Unscrew the central bolt and remove the pump pulley from the camshaft. If this bolt is too tight, you will have to remove the timing case sections and block the camshaft sprocket while loosening the bolt (this is necessary in order not to damage the timing belt). Remove segment key (if it falls out).

16. Pull out the old oil seal using a suitable hook.

17. Clean the stuffing box seat.

18. Lubricate the sponge of the new oil seal and install it on the end of the camshaft with the open end inward. Press the oil seal in so that it is flush with the end surface of the cylinder head (see photo). The gland can be pressed in using a bolt with washers and a suitable socket wrench.

19. Install a segment key on the camshaft (if filmed) and pump pulley, insert the central bolt.

20. Install the drive belt on the camshaft and vacuum pump pulleys and then turn the pump back so that when you press hard with your thumb, the belt deflection at the midpoint between the pulleys is approximately 5.0 mm. Tighten the adjusting and then the pump pivot bolts. Where applicable, install the power steering pump drive belt in the same manner.

21. Install the air cleaner.

22. Install the air inlet.

Crankshaft oil seal (from the timing belt side)

23. Remove timing belt (see section 4).

24. Remove the sprocket and key from the crankshaft (if the last one falls).

25. Note the installation depth of the gland and pull it out of the housing using a suitable hook. Alternatively, you can drill a small hole in the stuffing box, screw a self-tapping screw into it and use it to pull out the stuffing box.

26. Clean the oil seal housing and crankshaft, dip the new oil seal in engine oil and press it in (open end inside) on the crankshaft so that it stands at the desired depth. In order not to damage the oil seal, you can use a thin plastic strip (see photo).

27. Install the key and sprocket onto the crankshaft.

28. Install timing belt (see section 4).

Crankshaft oil seal (flywheel side)

29. Remove the flywheel (see section 16).

30. Using a vernier caliper, measure the installation depth of the stuffing box and record it.

31. Pull out the oil seal using a suitable hook. Alternatively, you can drill a small hole in the stuffing box, screw a self-tapping screw into it and use it to pull out the stuffing box.

32. Clean the gland seat and crankshaft flange.

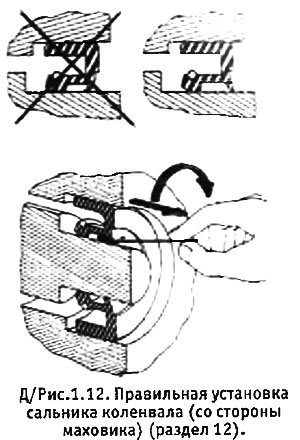

33. Dip a new oil seal in engine oil, install it on the crankshaft (open end inside) and press it in so that it is at the desired depth. In order not to damage the oil seal, you can use a thin plastic strip (see photo). At the installed stuffing box, the sponge should look outward - if it is bent inward, you need to pull it out with a hooked wire (see d/fig. 1.12).

|  |

34. Install the flywheel (see section 16).