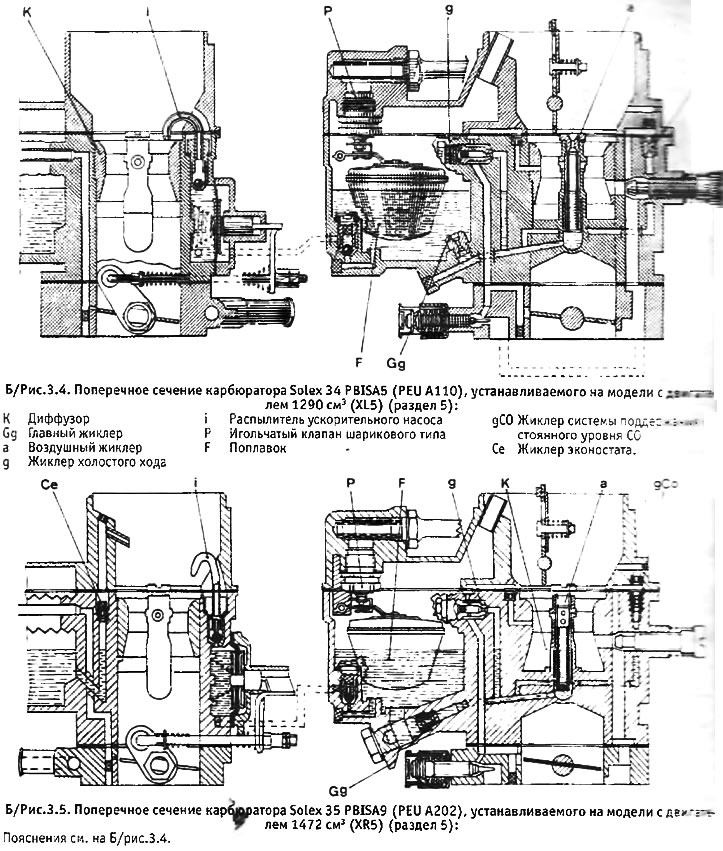

Both types of carburetors are single barrel outflow carburetors and have the following features:

- A. cold start device

- b. idle system

- V. system for maintaining a constant level of CO

- d. transitional system

- e. main system

- e. diaphragm type accelerator pump

In addition, the 35 PBISA9 carburetor fitted to the SR models is equipped with an economizer.

The carburetor works according to the usual principle. Fuel enters it through a strainer and fills the chamber to a level that is set by a float-controlled valve.

At the operating speed of the engine, the vacuum created in the diffuser sucks the fuel through the main jet into the emulsion tube that goes into the diffuser, where the fuel-air mixture enters the main air stream. The flow of the combustible mixture is regulated by a conventional throttle valve.

At idle, due to insufficient vacuum in the diffuser, the air-fuel mixture is supplied to the edge of the almost closed throttle valve, where there is a greater vacuum. The carburetor has quality and quantity screws to adjust the idle speed.

The econostat on the 35 PBISA9 carburetor delivers fuel to the outlet above the diffuser, where at open throttle there is enough vacuum to force fuel into the air pan. At low engine speeds, when the throttle is almost closed, this vacuum decreases and fuel injection stops. Due to this, the engine receives a leaner mixture at low speeds, a lean mixture at high engine speeds would lead to overheating of the engine and, possibly, to mechanical damage.

The air damper is equipped with a poppet valve, which is slightly spring-loaded and thus is in the closed position. When starting the engine with a starter, the poppet valve remains closed, which enhances the suction effect and facilitates starting the engine. After the engine starts, the poppet valve opens and the suction effect is reduced.

A diaphragm-type accelerator pump injects fuel directly into the diffuser each time the throttle is opened. The pump is refueled again when the throttle is closed. The fuel supplied by the accelerator pump makes it possible to achieve smooth acceleration of the engine, because otherwise, due to the inertia of the fuel at the first moment of acceleration, the fuel-air mixture would be lean.