Description and Precautions

1. The electronic ignition system installed on the latest models uses electrical impulses generated by the distributor for its work. The pulses are generated by magnetic induction and amplified by the ignition module, which supplies a low voltage current to the coil. The high voltage is generated and transmitted in the traditional way.

2. Electronic ignition systems are generally very reliable as they do not have a contact breaker, the wear of which over time leads to a breakdown in the system.

3. Be careful not to damage the ignition module or distributor by applying reverse polarity current or too much voltage (for example, you cannot use the fast charger while the battery is connected). There can be very high voltages in the electronic ignition system - be careful not to get electrocuted.

Electronic maintenance (contactless) ignition systems

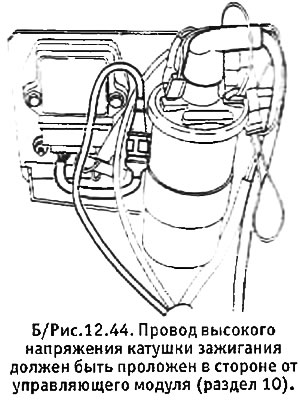

4. Routine maintenance of the system is limited to periodic cleaning and replacement of spark plugs. At the same intervals, clean and inspect the high voltage wires, the ignition coil and the distributor cover. From time to time, you should inspect the cover of the distributor (from within) and the slider for burning and the presence of cracks and at the same time lubricate the mechanism of the centrifugal ignition regulator with light oil.

5. Check that the coil high voltage wire is routed away from the control module (see b/fig. 12.44). If this wire is too close to the ignition module or wires, the flash may be missed and the tachometer needle may move erratically.

Removal and installation of contactless distributor

6. Unclench the clamps and remove the cover of the distributor by bending back the protective rubber cover. Mark the relative position of the distributor mounting flange and the thermostat/fuel pump housing.

7. Loosen the pressure plate and disconnect the low voltage wire (see pictures).

|  |

8. Unscrew 2 fixing nuts and pull out the distributor (see photo).

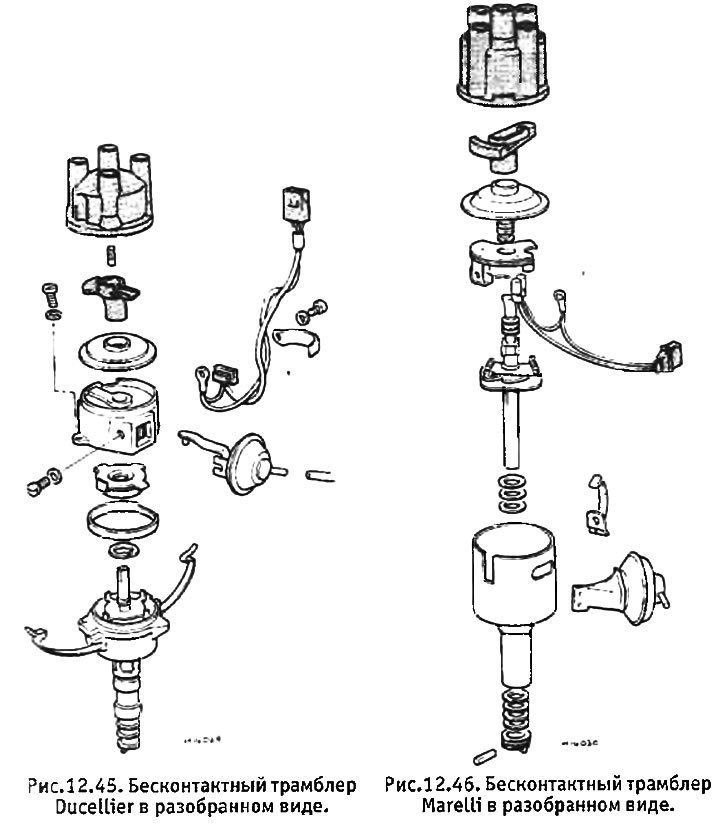

9. The distributor is installed in the reverse order. The distributor has an offset drive, so it is impossible to install it incorrectly. When installing a new distributor, align it in the middle of the travel permitted by the slots in the drive.

10. Check and, if necessary, adjust the ignition timing.

Contactless distributor - disassembly and assembly

11. Before starting disassembly, check if spare parts are available. If the mechanical parts of the distributor are worn out, it will have to be replaced as an assembly.

Trambler Ducellier

12. Begin disassembly by removing the screws holding the top and bottom halves of the distributor housing together. Mounting tabs are offset to ensure proper assembly of the distributor. Disconnect body halves.

13. Pull out the coil of the electromagnetic sensor and the vacuum unit from the upper half of the housing (pay attention to which hole the vacuum block rod is inserted into). Remove the retaining ring from the roller, after which it will be possible to remove the rotor and weights of the centrifugal ignition regulator. The drive pawl is attached to the roller with a pin.

14. The distributor is assembled in the reverse order.

Bosch/Marelli distributor

15. The disassembly procedure is similar to that just described, however, the distributor housing is made in one piece (see pictures). Remove the top plate and retaining ring from the roller.

|  |

Ignition timing control

16. In the case of an electronic system, static ignition control is not possible. On the rim of the distributor housing there is a mark corresponding to the position of the slider during a flash in cylinder No. 1. This mark can be used when adjusting the ignition timing "from scratch".

17. Dynamic adjustment is made by means of a stroboscope connected to ignition wire No. 1. On engines of the XU series, alignment marks are made on the rim and flywheel housing, and they can be seen without any disassembly (see photo).

18. Disconnect and plug the vacuum tube and then check the ignition timing at idle.

Removal and installation of the electronic ignition module

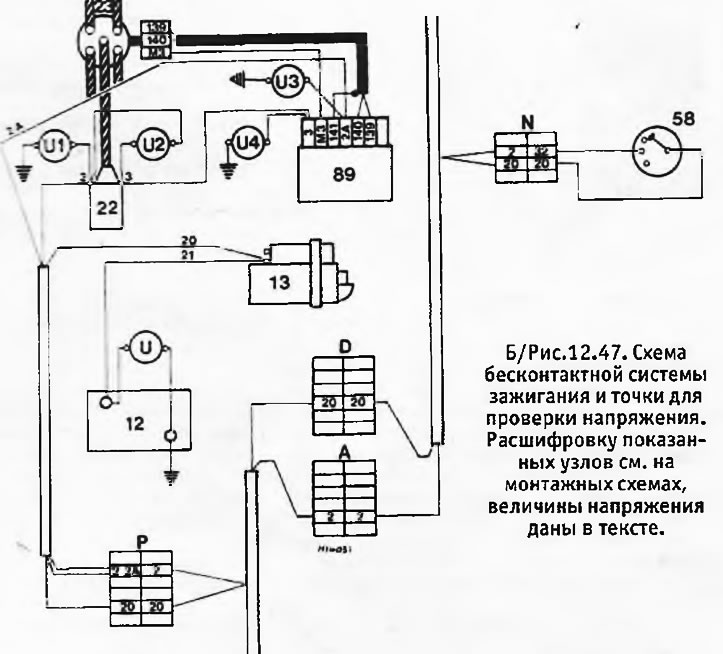

19. Remove the cover from the coil and module (see photo).

20. Disconnect the wiring harness from the module.

21. Remove the 2 fixing screws and remove the module from the base plate.

22. The module is installed in the reverse order.

Door locks with remote control

23. On the latest GTX models, the door locks are controlled remotely using a special controller, and not from the ignition key.

Troubleshooting

24. In case of system malfunctions, check (with a strobe), whether there is high voltage on the wire connecting the coil to the distributor. If there is voltage, then the fault lies in the high voltage distribution system (see section 14).

25. Check how the high voltage wire of the ignition coil is routed (see above).

26. If there is a multimeter, check the resistance of the windings of the pulse generator coil in the distributor and the ignition coil. (First you need to turn off the ignition and disconnect the tested coil). The required resistance values are specified in Specifications.

27. Inspect the pulse generator coil for mechanical damage and check the gap between the rotor and the stator, which should be the same for all 4 rotor poles. If mechanical damage is found, the distributor must be replaced. (On distributors with a top base plate, the rotor clearance can be changed after the plate is removed).

28. Using a multimeter or a low-wattage 12 V bulb, check the voltage at the points shown in B / fig. with the ignition on. 12.47.

You should get the following results:

- U (at the battery terminals) = minimum 11 V

- U1 (terminal + ignition coils) = battery voltage. If not, then the coil power wire is damaged

- U2 (at the low voltage terminals of the ignition coil) = 0 V. If there is voltage here, then either the module is faulty, or the wire connecting the coil to the module is damaged, hit the ground

- U3 (terminal 15 of the module) = battery voltage. Zero voltage here indicates a break in the wire from the connector to the module

- U4 (terminal 16 of the module) = battery voltage. Zero voltage here indicates a break in the wire from the ignition coil to the module.

29. Further diagnostics of the system should be performed by a specialist.