2. Release the clamps of the distributor cover and remove it. Wipe the cover with a dry, clean cloth and inspect the electrodes for excessive burns. See if there are any cracks on the lid. If the electrodes are burned or cracked, the cover must be replaced.

3. Inspect "ember" in the center of the cover for damage. Click on it a few times and check that it can move freely.

4. Carefully remove the slider from the cam and wipe it with a dry, clean cloth. A burnt or cracked runner should be replaced.

|  |

5. Using a small screwdriver, carefully open the breaker contacts and inspect them carefully. If they are worn, burned or dirty, they must be removed for repair or replacement (see section 4).

6. If the contacts are in good condition, turn the crankshaft in the direction of its rotation with a wrench thrown over the crankshaft pulley bolt so that the back side of the movable contact is at the top of one of the cam contours.

7. Using probes of the desired thickness (see specs) check the gap between the contacts. The probe should pass between the contacts with a slight tightness, without spreading them apart. Be careful not to oil the contacts during the test.

8. If adjustment is required, proceed as follows (depending on brand of distributor).

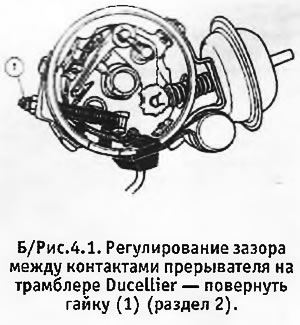

9. Ducellier. Using a 7mm open-end wrench or ring spanner, turn the adjusting nut on the side of the distributor to obtain the desired clearance (see photo).

10. Paris-Rhone. Insert a 3mm hex wrench into the hole in the plastic plug on the side of the distributor so that it fits into the recess on the fixed contact and turn the wrench to obtain the desired clearance.

11. When finished, turn the crankshaft so that the back of the moving contact is at the top of the next cam contour and check the clearance again. Any change in the gap indicates that the distributor needs repair. In case of significant changes, the roller must be replaced.

12. Reinstall the slider and distributor cover. Secure the cover with clips.