2. Mark the ignition wires so that they can be connected later in the same order, and carefully disconnect them from the spark plugs. Disconnect the high voltage wire from the ignition coil, release the clamps and remove the distributor cover with wires.

3. Disconnect the low voltage wire connecting it to the distributor from the coil.

4. Disconnect the vacuum tube from the vacuum capsule.

5. Turn the crankshaft with a wrench thrown over its pulley bolt so that the slider comes to the place where electrode No. 2 is located on the distributor cover. Continue turning the crankshaft until the notch on the pulley rim is aligned with the first notch (in the direction of rotation of the crankshaft, i.e. clockwise when looking at the pulley) on the setting scale on the clutch housing.

6. Mark the position of the distributor housing relative to the casing of the gas distribution mechanism so that later it can be installed exactly in its original position. Unscrew and remove the bolt with spring washer. Be careful not to drop the pinch bolt into the base plate.

7. Carefully pull the distributor out of the casing of the gas distribution mechanism.

8. If, when the distributor was removed, you did not touch the crankshaft and the casing of the gas distribution mechanism, then before installing the distributor, you should check that the notch on the crankshaft pulley is still aligned with the first notch on the installation scale on the clutch housing.

9. Turn the distributor roller so that the slider is opposite the N 2 electrode on the distributor cover. Check that the tabs on the end of the distributor roller line up with the offset slot in the roller drive. Insert the distributor into place and check that the protrusions are in the slot. If necessary, you can slightly rotate the body and ensure that the marks made before removing the distributor are aligned. Install and tighten the bolt with washer securing the distributor clamping plate. Upon completion, check that the slider is still opposite the No. 2 electrode.

10. If, with the distributor removed, for some reason you removed the casing of the gas distribution mechanism, several additional operations should be performed when installing the distributor.

11. First of all, turn the crankshaft to the correct position. This is hampered by the fact that on the rear flange of the crankshaft pulley there are 2 notches spaced 180°apart. These notches are used to determine the difference between the ignition timings in all 4 cylinders using a strobe light while the engine is running. The ignition timing is controlled by cylinder No. 2, and in order to determine which notch to use, you need to turn the crankshaft in the normal direction of its rotation (clockwise when looking at the pulley) so that the piston number 2 began to rise on the compression stroke. This can be determined by removing the valve cover and observing when both valves in cylinder No. 2 close. In this position, one of the notches on the pulley should be next to the setting scale. Rotate the crankshaft again so that the notch on the pulley aligns with the first notch on the setting scale. Check that cylinder no. 2 is still on the compression stroke.

12. Now you can install the distributor (see paragraph 9). Skip the label alignment instructions if this is not the case.

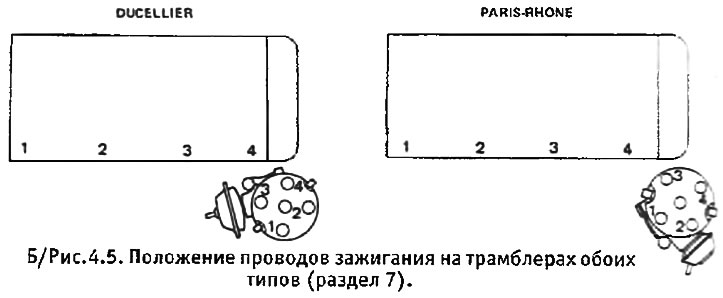

13. After installing the distributor, check the ignition timing (see section 10) and tighten the clamping bolt and clamping plate fixing bolt. Replace the distributor cover and connect the ignition wires and the low voltage wire. Connect the high voltage wire to the ignition coil and the vacuum tube to the vacuum chamber. The correct position of the ignition wires is shown in B / fig. 4.5.