2. The camshaft journals must be in good condition and not particularly worn, as there is almost no stress on them.

3. If the camshaft bearings are obviously worn or discolored, the camshaft may need to be replaced. Contact a specialist to accurately check the camshaft and cylinder head.

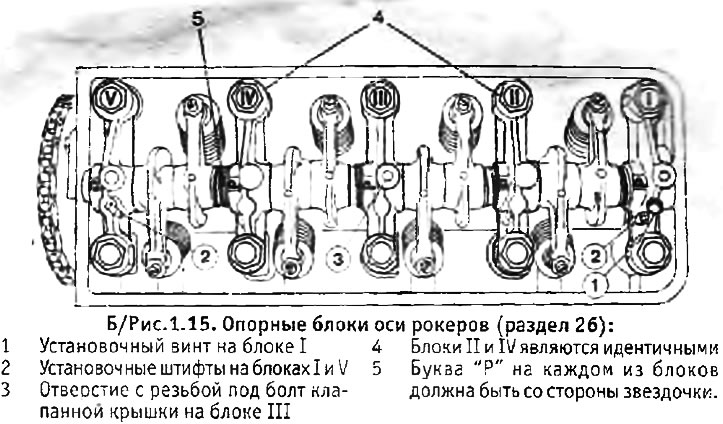

4. The rocker mechanism can be disassembled after removing the set screw on the support block from the side opposite the camshaft sprocket (see fig. 1.15, paying attention to the difference between the blocks). Disassemble the rocker mechanism, laying out its parts in order for cleaning and inspection.

5. Inspect the rocker axle for signs of wear and check for distortion by rolling it on a flat surface. Axle distortion is unlikely, but if it does occur, the axle should be straightened or replaced. There should be no protrusions on the surface of the axle caused by wear. Inspect the oil holes and clean them if they are clogged.

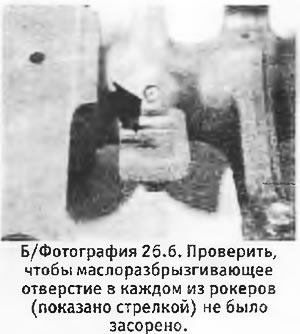

6. Check the rockers for bearing wear by moving them to a non-worn part of the axle. Inspect the oil spray holes and make sure they are not clogged. Inspect the ends of the valve clearance screws for cracks or wear. Defective screws must be replaced.

7. Assembly of the rocker mechanism is carried out in reverse order. Lubricate all bearing surfaces with clean engine oil, with the exception of the rocker thrust pads, which should be lubricated with Molykote after the rockers have been installed on the cylinder head. Check that all parts are installed correctly.