- A. Generator and its drive belt.

- b. Oil filler tube and crankcase breather tube (memorizing their location).

- V. intake manifold and carburetor.

- g. Clutch.

- e. Oil filter (be prepared for oil to spill).

- e. Coolant manifold and hoses (memorizing their location).

- and. Oil pressure switch.

- h. power steering pump (if available).

36. The exhaust manifold can either be removed at this stage or left in place so that you can hold on to it while removing the cylinder head.

37. Remove the bolt and remove the crankshaft pulley. While removing the bolt, block the flywheel ring gear so that the crankshaft does not turn.

38. Remove the camshaft drive belt covers, paying attention to what size bolts are where.

39. Remove the bolts and remove the camshaft cover.

40. Turn the crankshaft through the flywheel so that a 10 mm diameter bar can be inserted into the hole in the camshaft sprocket and then into the recess in the gas distribution mechanism. The pistons are now at mid stroke so they can't hit the valves.

41. Loosen the camshaft drive belt tensioner by loosening its nuts (two in front and one behind the front plate) and, holding the square roller of the tensioner cam, move the cam to a horizontal position.

42. Remove the camshaft drive belt, being careful not to twist it. If you are not going to change the belt, you should remember how it stood and in which direction it moved.

43. Remove the bolts and remove the drive belt tensioner.

44. Remove the belt side shields and crankshaft sprocket. Pull out the segment key.

45. Remove the bolt and remove the camshaft sprocket. While the bolt is being removed, the sprocket can be kept from turning by inserting a 10 mm bar into the mounting hole on the sprocket (see photo).

46. Remove the bolts and remove the engine support bracket, camshaft sprocket support shield and water pump.

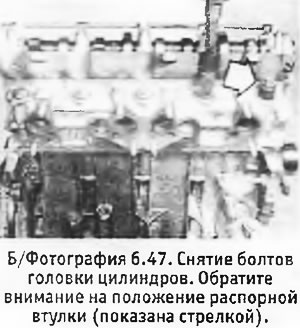

47. Loosen 10 cylinder head bolts in reverse order of their tightening (see fig. 12.4). Remove the bolts with washers, paying attention to the spacer under the bolt N 8 (just above the water pump) (see photo).

48. Remove the cylinder head. If it does not come off, insert 2 metal bolts into the bolt holes and try to swing the head. It is forbidden to hit the head or try to pry it with a lever. After removing the head, move aside 2 dowel pins (if they fall).

49. Install temporary cylinder liners if you are not going to remove the pistons with liners. Turn the engine over to remove the bolts and remove the flywheel. It has special mounting slots so that it can only be installed in one position.

50. Disconnect the suction drain tube from the side of the sump (see photo).

52. To turn out bolts and to remove the pallet. Pay attention to the position of the 3 hex bolts (see photo).

53. Unscrew the bolts securing the oil pump, paying attention to the special centering bolt standing behind.

54. To turn out bolts and to remove a plate of the case of an epiploon.

55. Lower the oil pump into the engine so that its drive chain can be removed. Pull out the pump and remove the spacer, dowel pins and chain.

56. Remove the oil pump sprocket from the crankshaft and pull out the segment key.

57. Remove the connecting rod cap bolts and push the pistons out through the top of the cylinder liners. (If you are not going to change the pistons, before removing them, you must remove the ledge at the top of the sleeves using a special tool or a scraper). Mark pistons, connecting rods and connecting rod caps so that they are not confused during assembly.

58. Unscrew the bolts of the main caps NN 1, 2, 4 and 5. Also remove the 2 nuts and 2 side bolts from the central cap. Make marks on the covers indicating their relative position and remove them. If you are not going to change the bearing shells, they should be left in the caps. Remove the halves of the thrust washers on both sides of the No. 2 main cover.

59. Remove the oil seal from the end of the crankshaft on the flywheel side.

60. Pull the crankshaft out of the crankcase. Remove the top halves of the main bearing shells and the remaining two halves of the thrust washers.

61. If you are not going to change the cylinder liners, make alignment marks on them, loosen the clamps and remove the liners. Engine disassembly completed.