54. Drain the liquid from the cooling system.

55. Loosen, without removing, the central bolt and nut of the gum of the lower engine mount.

56. Remove the air cleaner with tubes and channels and disconnect the crankcase ventilation tubes.

57. Unscrew the nut that secures the rubber band of the right engine mount.

58. Carefully raise the engine by 6-8 mm using a hoist or a reliable jack. Remove the 2 bolts securing the right engine support bracket to the cylinder head and lower the engine back into place.

59. Disconnect the fuel, water and vacuum tubes from the cylinder head, carburetor and manifold, noting their position or marking so as not to confuse when connecting. Disconnect the throttle cable and wiring harness.

60. Disconnect the exhaust pipes from the exhaust manifold flange.

61. Remove the water tube from the pump inlet housing. Pull the diagnostic socket out of its bracket and unscrew the bolt securing the oil filler tube to the intake manifold (see pictures).

62. Remove the valve cover and distributor cover with high voltage wires.

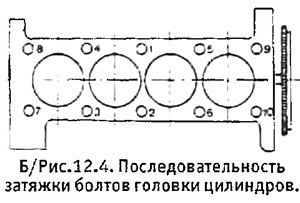

63. Loosen the cylinder head bolts in the reverse order of their tightening (see b/fig. 12.4). Remove bolts.

64. Remove the cylinder head, loosening it if necessary with two rods inserted into the holes for the head bolts. Remove the head gasket and loose pins. Be careful not to turn the crankshaft, because. this will dislodge the cylinder liner seals and require the engine to be removed to reinstall the seals.

65. Secure the sleeves in place with clamps or large washers secured with nuts and bolts (see photo). If the sleeves are dislodged, the engine will have to be removed to install new seals.

66. Start installing the cylinder head by installing the guide pins on the block. Pry up the pin on the flywheel side by inserting a 5 mm punch or large nail into the hole on the front face of the block (see photo). Remove the clamps securing the sleeves.

67. Install a new cylinder head gasket (dry) projection towards the flywheel. Lower the head into place, making sure that it is seated on the dowel pins. Pull out the punch (or a nail), holding the pin in an elevated position.

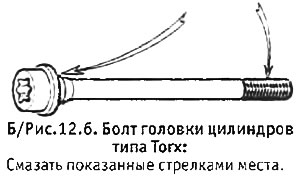

68. Insert the cylinder head bolts after cleaning and lightly oiling their threads. Don't forget to install a washer under the bolt above the water pump.

|  |

69. Gradually tighten the bolts in the sequence shown in B / fig. 12.4, until the time specified in Specifications for stage 1.

70. Raise the engine slightly and install the 2 bolts securing the right engine support bracket to the cylinder head. Tighten these bolts and loosen the bolt holding the same bracket to the cylinder block. Lower the engine and tighten the right cushion mounting nut and bottom cushion rubber nut and bolt.

71. Loosen bolt N 1 of the cylinder head and immediately tighten it to the torque specified in the Specifications for step 2. Tighten this bolt to the angle specified in Specifications for step 3. Repeat these steps for the rest of the bolts, working in the tightening sequence.

72. Check and, if necessary, adjust valve clearances.

73. Install the remaining parts in the reverse order of their removal.

74. Fill the system with coolant and pump it.

75. Start the engine, warm it up to operating temperature, at which the cooling fan will turn on, and then turn off the engine and allow it to cool for at least 2 hours.

76. Re-tighten the cylinder head bolts as directed in paragraph 76 and recheck the valve clearances.

77. If a new camshaft drive belt is installed, tighten it again as indicated in paragraph 42.

78. Tighten the engine support bracket bolt.