- remove the shock absorber from the car;

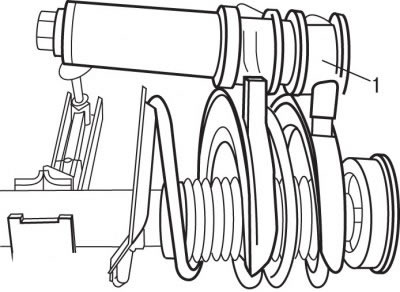

Pic. 6.5. Shock absorber spring compression with MG INTERNATIONAL tool (1)

- fix the front shock absorber strut in a fixture fixed in a vise and using the special tool MG INTERNATIONAL or U77 FACOM compress the spring so that it moves away from the top of the strut (pic. 6.5). When using a special device for compressing springs, the coils of the spring must be securely gripped, the spring must be compressed from opposite sides;

Attention! The spring has a very high compression force, so use only a reliable tool. Never tie the spring with wire.

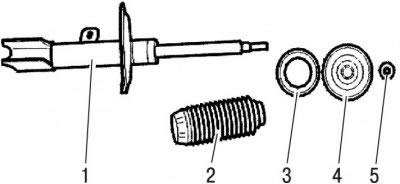

Pic. 6.6. Elements of the suspension strut: 1 - shock absorber; 2 - protective cover; 3 - emphasis; 4 - upper spring support; 5 - nut, 69 Nm

- having fixed the shock absorber rod from turning with a wrench and using another ring wrench or a special TORX 45 key, unscrew the central nut of the shock absorber rod (pic. 6.6);

Attention! The central nut of the shock absorber rod can only be turned out when the spring is compressed.

- remove the upper spring support 4, stop 3 and protective cover 2 of the shock absorber rod from the shock absorber rod;

- release the fixture and check the condition of the spring, if damaged (cracks in the coils or their deformation) replace the spring.

The main ways to check the shock absorber:

1) Typical signs that indicate a malfunction of the shock absorber are:

- prolonged rocking of the body when driving on uneven road surfaces;

- increasing body sway when driving on uneven road surfaces;

- uneven and unstable wheel movement (bouncing) when driving in a certain range of speeds, including cornering;

- deviation from the given trajectory of the vehicle during braking;

- unstable cornering and skidding of the car;

- increased tire wear, characterized by abrasion of the tire pattern;

- the appearance of clicks and extraneous noise when the car is moving. Clicks and slight impacts can also be caused by other suspension malfunctions, in particular, loosening of threaded connections, failure of hub bearings or wear of the constant velocity joints of the drive shafts;

2) to check the technical condition of the shock absorber, remove it from the car;

3) inspect the body and shock absorber rod. There should be no mechanical damage on the body, and traces of corrosion on the stem. Set the shock absorber to a vertical position and check its operation by moving the shock absorber rod through the entire stroke and up and down for a length of 50-100 mm. In all cases, the shock absorber rod should move smoothly with perceptible resistance. If the stem moves jerkily or is damaged, the shock absorber must be replaced;

4) The rod of a gas-filled shock absorber can spontaneously extend out of the shock absorber. The absence of spontaneous extension of the rod from the shock absorber does not indicate a malfunction of the shock absorber. In this case, the operating mode of the gas-filled shock absorber corresponds to the operating mode of the hydraulic shock absorber. The shock absorber performs its functions even in the absence of excess gas pressure, but additional noise may appear when the piston moves;

5) Check for shock absorber fluid leaks. A small oil leakage is allowed while maintaining the normal performance of the shock absorber. It is normal if the fluid leak from the damper only extends to the lower spring seat. With a slight leakage of fluid from the shock absorber, the sealing ring of the shock absorber rod is lubricated, which increases its service life;

6) If there are severe fluid leaks, replace the shock absorber.

Attention! When installing, it is necessary to use springs with the same technical characteristics on the same axle of the car (with the same color marking).

Assemble the shock absorber in the reverse order of removal, taking into account the following:

- while holding the shock absorber rod from turning, screw on a new shock absorber rod mounting nut and tighten it to 69 Nm;

- check that the upper coil of the spring is correctly located on the upper spring seat;

- install the shock absorber on the car.