Removing

Switch off ignition and disconnect a wire from the negative plug of the storage battery.

Remove the integrated air supply system.

Use SODIMAC 35 to clean the union nuts of the high pressure fuel pipes and the area around the nuts.

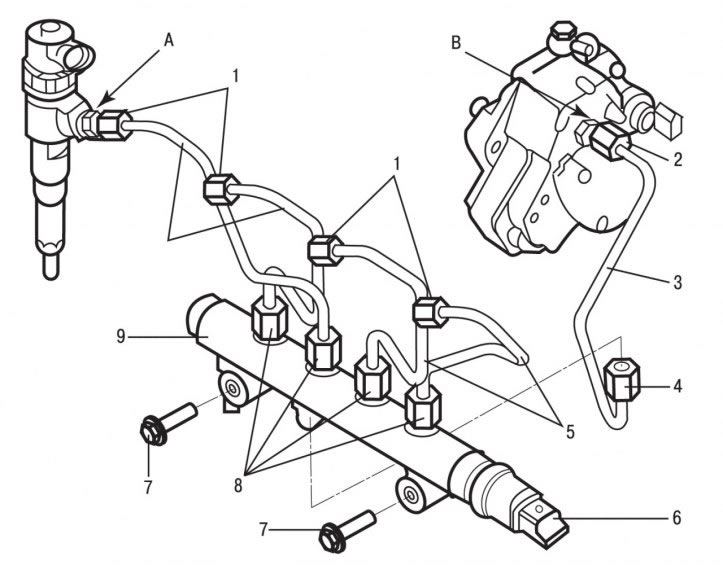

Pic. 4.35. Location of fuel supply pipelines to injectors: 1, 2, 8 - connecting nuts; 3 - high pressure fuel pipe; 4 - connecting nut; 5 - high pressure fuel pipes; 6 - high pressure sensor; 7 - bolts; 9 - fuel distributor (Common Rail); A - hexagon on the nozzle; B - hexagon on the high pressure fuel pump

Hold the hexagon B with a wrench (see fig. 4.35) on the high pressure fuel pump, use the second wrench to unscrew the union nut 2 fastening the high pressure fuel pipe 3.

Unscrew the connecting nut 4 fastening the high pressure fuel pipe 3 to the fuel distributor (Common Rail) and remove the fuel pipe.

Holding the hexagons A on the injectors with a wrench, use the second wrench to unscrew the connecting nuts 1 fastening the high-pressure fuel pipes 5 to the injectors.

Unscrew the connecting nuts 8 fastening the high pressure fuel pipes 5 to the fuel distributor (Common Rail) and remove the fuel lines. To prevent dirt from entering, close the fuel pipes and fittings on the fuel distributor with suitable plugs.

Disconnect the high pressure sensor connector 6.

Turn out bolts 7 and remove the fuel distributor (Common Rail).

Attention! Do not unscrew the high pressure sensor from the fuel distributor (Common Rail).

Installation

Attention! When installing the fuel distribution line, use new high pressure fuel lines.

Install fuel distributor 9 (see fig. 4.35) and secure with bolts 7, finger-tight at this stage.

Install the high pressure pipe 3 and secure it with connecting nuts 2 and 4, tightening them first with a torque of 17 Nm, and then finally with a torque of 22 Nm. When tightening the union nut on the high pressure fuel pump, hold the hexagon B with a wrench.

Install the high-pressure fuel pipes on the injectors and the fuel distributor and secure them with connecting nuts, tightening them first with a torque of 17 Nm, and then finally with a torque of 22 Nm. When tightening the connecting nuts on the injectors, hold the hexagons A with a wrench.

Tighten the fuel distributor mounting bolts to 22 Nm.

Install an integrated air supply system.

Connect the wire to the negative battery terminal.

Start the engine.

Check the tightness of the connections.

Increase the engine speed to 3500 min-1.

Check the tightness of the connections.