On vehicles with diesel engines, an unregulated oxidative catalytic converter is used to reduce the toxicity of exhaust gases.

Reducing the content of nitrogen oxides in the exhaust gases of a diesel engine is achieved by installing an exhaust gas recirculation system on the car (EGR).

Through the EGR valve on a warm engine, part of the exhaust gases is directed to the combustion chambers of the engine, as a result of which the temperature decreases and the content of nitrogen oxides in the exhaust gases decreases.

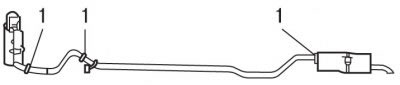

Pic. 4.41. Exhaust system: 1 - clamps, 25 Nm

Elements of the exhaust system are connected by clamps, the fastening bolts of which must be tightened with a torque of 25 Nm (pic. 4.41).

After servicing and repairing the exhaust system, check that the system is installed freely, without stress, with sufficient clearance relative to the body elements.

To facilitate the subsequent unscrewing of the nuts and bolts that secure the system, lubricate them with high-temperature paste, such as Liqui Moly LM-508-ASC.

Before re-assembling the elements of the exhaust system, clean their joint with sandpaper from the remnants of sealant and rust.

Attention! The connecting element in the front exhaust pipe must be protected from any mechanical damage. The connector in the front exhaust pipe must not be bent by more than 20°, or misaligned by 20 mm axially and 25 mm radially, otherwise it will be damaged.