Diesel engines are equipped with a fuel heating system.

Conditions for working with the SIEMENS power system

Attention! Additives such as fuel system cleaner must not be added to diesel fuel.

Security measures

All work on the fuel injection system must be carried out in accordance with established requirements and regulations that ensure the prevention of accidents and the protection of the environment.

The work must be carried out by specially trained personnel who are aware of the safety recommendations and the measures to be taken.

Given the very high pressures (1500 bar), that are created in the fuel system, follow these recommendations:

- smoking is prohibited in the immediate vicinity of the high pressure hydraulic circuit during work;

- it is forbidden to work near an open flame or sparking objects;

- it is forbidden to carry out work on the high-pressure hydraulic fuel circuit with the engine running;

- before starting any work on the fuel system, wait 30 seconds after stopping the engine.

With the engine running:

- always stay out of reach of the jet of fuel, which may accidentally escape from the nozzle, as this can cause serious injury;

- keep your hands away from high pressure fuel circuit leaks.

The place of work must be clean and away from the work area with other vehicles. Parts removed during repairs should be stored in places protected from dust.

Attention! Do not disconnect the connectors from the injectors and the computer, as this may damage the engine.

Before working on the fuel system, clean the following elements of the fuel system:

- fuel filter;

- high pressure fuel pump;

- fuel distributor (Common Rail);

- high pressure fuel pipes;

- nozzles.

Plug the high pressure pipes immediately after removal to prevent dirt from entering the high pressure circuit.

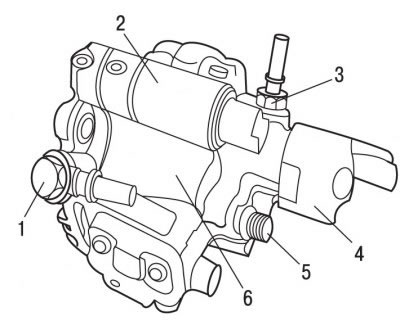

Pic. 4.67. Elements of the SIEMENS high pressure fuel pump: 1 - fitting of the supply pipe of the fuel pump; 2 - solenoid valve for volume control; 3 - fuel return screw; 4 - pressure control solenoid valve; 5 - high-pressure fuel outlet fitting; 6 - high pressure fuel pump

It is forbidden to disconnect or remove from the fuel pump 6 (see fig. 4.67) high pressure the following items:

- pressure control solenoid valve 4;

- volume control solenoid valve 2;

- high pressure fuel outlet 5;

- fitting of the supply pipe of the fuel pump 1;

- fuel return screw 3.

It is forbidden to disconnect the high pressure sensor from the end face of the fuel distributor.

Attention! Before carrying out any work on the engine, read the memory of the injection control unit.

It is forbidden to disconnect or remove the following items from the injector:

- spray;

- solenoid valve winding;

- turn or loosen the hex nuts.

When replacing the fuel system control unit, it is necessary to initialize the engine blocking system.

To perform initialization, the following conditions must be met:

- have an access code to the analog module (recorded on a confidential client card);

- have a new fuel system control unit and diagnostic tool;

Attention! It is forbidden to clean carbon deposits from the nozzle spray tip, as well as clean with diesel fuel or ultrasonic. All work on high-pressure fuel pipes must always be accompanied by their mandatory replacement.

- initialize the engine control unit;

- wire the engine control unit.

Telecoding is carried out using diagnostic tools.

The computer software is updated by downloading from DIAG 2000.

Attention! Swapping the injection computers on two vehicles makes it impossible to start the engine.

To unlock the fuel injection computer:

- turn on the ignition;

- wait until the engine start indicator goes out;

- disconnect the injection computer;

- turn off the ignition.