Removing

Switch off ignition and disconnect a wire from the negative plug of the storage battery.

Before starting any work on the fuel system, wait 30 seconds after stopping the engine.

Remove the decorative casing from the engine.

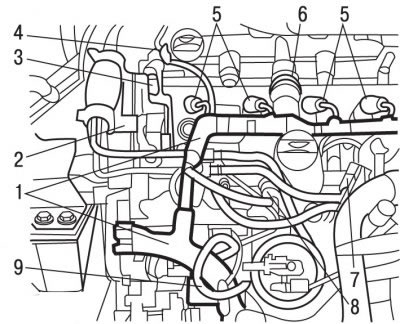

Pic. 4.69. Location of wires and connectors on the DW10TD engine: 1 - wiring harness; 2 - pump support for filling the system with fuel; 3 - support of the decorative casing of the engine; 4, 7, 8 - sensors; 5 - pin connectors; 6 - oil vapor trapping tube; 9 - fuel supply pipe

Disconnect the connectors from sensors 4, 7, 8 (see fig. 4.69).

Disconnect the connectors 5 from the injectors.

Set aside the wiring harness for 1 injectors.

Take aside the tube 6 for trapping oil vapors and the pump for filling the system with fuel.

Remove pump support 2 to fill the system with fuel.

Remove a support 3 of a decorative casing of the engine.

Remove tube 9 for fuel supply.

Disconnect the diesel pressure return line from the fuel pump.

Use SODIMAC 35 to clean the union nuts of the high pressure fuel pipes and around the nuts.

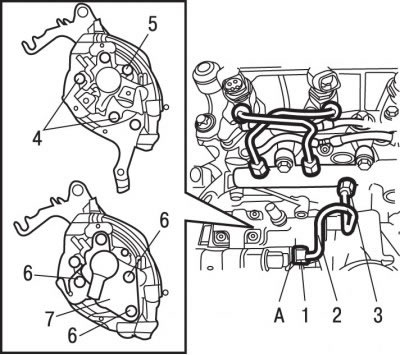

Pic. 4.76. High pressure fuel pump mounting: 1 - connecting nut, 25 Nm; 2 - high pressure fuel pipe; 3 - connecting nut, 28 Nm; 4 - bolts; 5 - nut; 6 - bolts; 7 - rear support of the high pressure fuel pump

Holding the hexagon A with a wrench (pic. 4.76) on the high pressure fuel pump, unscrew the connecting nut 1 fastening the high pressure fuel pipe 2 with the second wrench.

Turn away a connecting nut 3 fastenings of a fuel pipe 2 of a high pressure to the fuel distributor and remove a fuel pipe.

Turn out bolts 6 and remove them together with washers.

Remove the rear support 7 of the high pressure fuel pump.

Install cross member 0102-D to support the engine. Hook the crossbar catch onto the right engine lifting eye.

Remove the right engine mount.

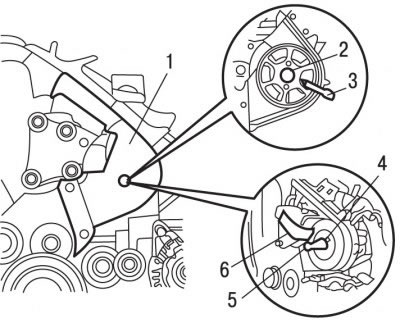

Pic. 4.77. Fastening of a pulley of the fuel pump of a high pressure: 1 - upper front casing of the toothed belt; 2 - nut; 3 - special pin 0188-V; 4 - additional hub 0188-AB; 5 - bolt; 6 - special tool for fastening the high pressure fuel pump pulley

Remove the top front cover 1 (pic. 4.77) toothed belt.

Using a special pin 0188-V, fix the fuel pump pulley from turning and unscrew the nut 2 fastening the pulley.

Install special tool 6 and additional hub 0188-AB 4 for high pressure fuel pump pulley mounting. Tighten the fastening bolts of the special tool 6 to 40 Nm, and the additional hub 4 to 15 Nm.

Turn out bolts 4 and a nut 5 (see fig. 4.76) fuel pump mountings.

Screw in bolt 5 (see fig. 4.77) securing the fuel pump pulley and remove the high pressure fuel pump.

Installation

Remove additional hub 0188-AB 4 (see fig. 4.77) fastening the pulley of the high pressure fuel pump.

Install the high pressure fuel pump.

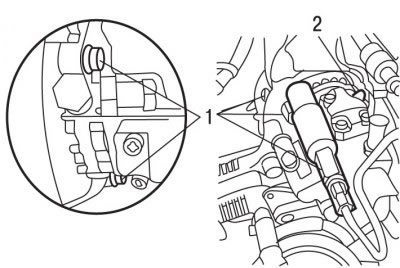

Pic. 4.78. Bolt location (1) and nuts (2) high pressure fuel pump mountings

Screw in and tighten bolts 1 and nuts 2 (pic. 4.78) fastening the fuel pump with a torque of 23 Nm.

Screw in and hand-tighten nut 2 (see fig. 4.77) fastening the pulley of the high pressure fuel pump.

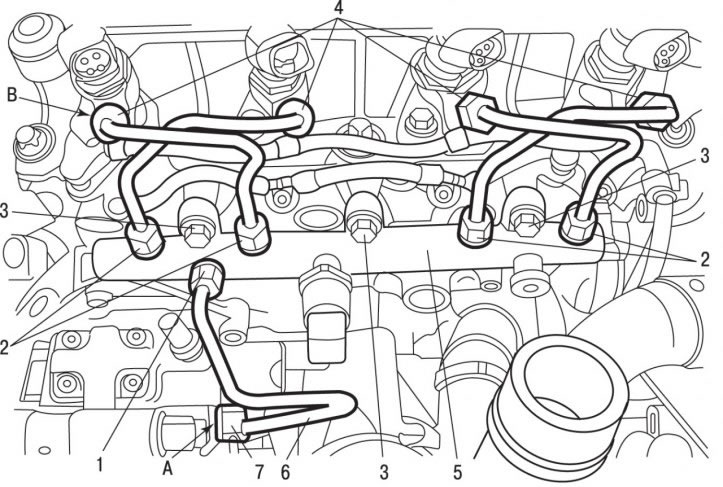

Pic. 4.68. Fuel distributor (Common Rail): 1, 2 - connecting nuts, 28 Nm; 3 - bolts, 23 Nm; 4, 7 - connecting nuts, 25 Nm; 5 - fuel distributor; 6 - high pressure tube; And - a hexagon on the union of an exit of fuel under a high pressure; B - hexagon on the nozzle

Install the high pressure pipe 6 and secure it with union nuts 1 and 7 (see fig. 4.68), tightening them at this stage by hand.

Pre-tighten the connecting nut fastening bolts to 24 Nm.

Tighten the connecting nut 1 fastening the high pressure pipe to the distribution fuel pipeline to 28 Nm.

Tighten the union nuts 7 fastening the high pressure pipe to the fuel pump 25 Nm.

Further installation is carried out in the reverse order of removal.

Tighten bolts 6 (see fig. 4.76) fastening the rear support of the fuel pump with a torque of 23 Nm.

Tighten nut 2 (see fig. 4.77) fastening the pulley of the high pressure fuel pump with a torque of 50 Nm.

Tighten the high pressure fuel pump stud to the support to 65 Nm.

Tighten the engine mount bolt to 60 Nm.

Fill the circuit with fuel using a manual priming pump.

Do computer programming.

Start the engine.

Check for fuel leaks.