Recommendations for removing the engine

Please read this section carefully before starting work.

If the engine is removed for repair, it is necessary to select a place for work, provide space for maintenance and storage of spare parts. Repairs are recommended to be carried out at a workshop or in a garage with a flat, horizontal floor with a clean hard surface.

Clean and wash the engine and engine compartment before removal. To remove, use a lifting device that allows you to safely lift the power package.

If you are removing the power unit for the first time, you must invite an experienced specialist. Some work should be done with an assistant.

All clamps and clamps that are damaged or cut when removing the engine are replaced with new ones when assembling the engine.

Depending on the year of manufacture and vehicle equipment, electrical wires, pipelines and hoses may be located in the engine compartment in different ways. Therefore, before disconnecting electrical connectors and disconnecting pipes or hoses, it is recommended to mark them with adhesive tape.

The engine is removed forward along with the gearbox.

Drained coolant must be collected and disposed of.

Removing

Place the car on a two post lift.

Open the hood to the service position and secure it with a bolt and nut system.

Remove the decorative casing from the engine.

Depressurize the fuel system by connecting special tool 0141-T1 to the SHRADER valve and collect the fuel in a container.

Drain the coolant.

Drain the gearbox oil.

Remove the accessory drive belt.

Remove the front wheels.

Remove the front bumper, headlights and bumper reinforcement.

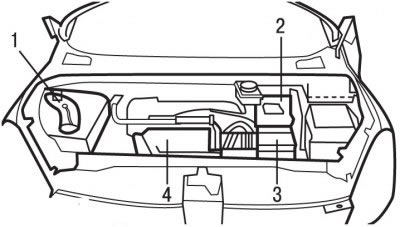

Pic. 3.51. Location of parts and assemblies in the engine compartment with the EW10J4 engine: 1 - upper right decorative cover; 2 - battery cover; 3 - air filter; 4 - resonator

Remove the upper right decorative cover 1 (pic. 3.51).

Remove air filter 3, resonator 4, throttle body cover and air intake.

Remove the flexible clutch cable.

Disconnect the hose from the vacuum brake booster.

Disconnect the fuel supply and return pipes, as well as the fittings of the fuel vapor suction pipes.

Remove battery cover 2.

Remove the left front wheel arch mudguard.

Remove the battery support bolt from under the left front wheel arch.

Remove the battery.

Remove the battery support.

Disconnect the constant velocity joints and shock-absorbing elements from the gearbox, mounted on the lower gearbox housing.

Using the special tools, disconnect the transmission control rods.

Disconnect the exhaust pipe from the exhaust manifold.

Remove the clutch drive mechanism.

Remove the jet engine mount bracket.

Attention! Do not open the cooling circuit of the air conditioning system.

Set aside and secure the air conditioning condenser.

Turn out bolts of fastening of the compressor of the conditioner and take away it aside, without disconnecting pipelines from it.

Loosen the clamps and remove the coolant supply hoses to the heater core.

Loosen the bolt and disconnect the wire «masses».

Disconnect the connector from the oxygen sensor.

Disconnect from the engine contact sockets.

Place a jack with a platform under the power unit and fasten the special devices for attaching the platform and engine.

Raise the platform jack so that the weight of the power package is supported by the jack.

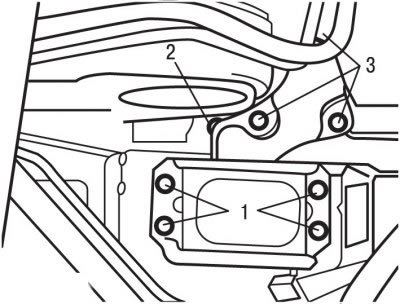

Pic. 3.52. Bolt location (1, 2, 3) engine bracket mounts

Remove bolts 1 and 3 (pic. 3.52) engine bracket mounting.

Remove the right upper engine bracket.

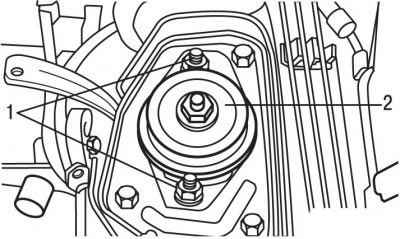

Pic. 3.53. Bolt location (1) and nuts (2) fixing the left intermediate support of the power unit

Remove bolts 1 (pic. 3.53) and nut 2 fastening the left intermediate support of the power unit and remove the support.

Make sure all electrical wires, hoses, fittings and pipes are disconnected from the engine.

Remove the power unit, being careful not to hook on the surrounding elements.

If necessary, disconnect the gearbox from the engine.

Installation

The engine is installed in the reverse order of removal, taking into account the following.

Replace with new self-locking nuts and bolts that have been tightened to a certain angle, as well as o-rings and gaskets.

Install the power unit.

Reinstall the left intermediate support, then the right intermediate support. Insert the support bolts and tighten the bolts 1 and 2 (see fig. 3.52) torque 60 Nm, bolts 1 (see fig. 3.53) torque 30 Nm and nut 2 torque 65 Nm.

Disconnect the special tools from the engine and lower the jack with the platform.

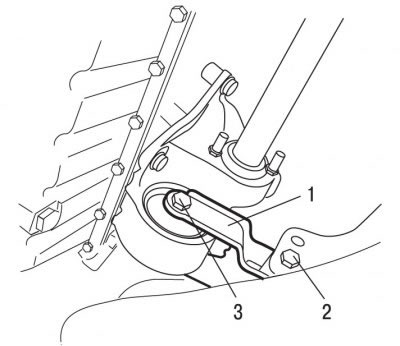

Pic. 3.54. The location of the engine mount jet bracket bolts: 1 - bracket; 2 - bolt, 55 Nm; 3 - bolt, 40 Nm

Reinstall reaction bracket 1 (pic. 3.54) engine mounts and tighten the bracket mounting bolts to the appropriate torque.

Connect the constant velocity joints to the gearbox.

Connect all connectors to the engine.

Connect wire «masses» and secure it with a bolt.

Connect the connector to the oxygen concentration sensor.

Connect the coolant supply hoses to the heater core.

Install the clutch drive mechanism.

Install and bolt the air conditioning compressor.

Install the air conditioning condenser.

Install the radiator.

Install the manifold exhaust pipes and secure them with bolts, tightening them to a torque of 25 Nm.

Install shock-absorbing elements on the lower gearbox housing.

Carry out further installation of the engine in the reverse order of removal, taking into account the following.

Install the accessory drive belt.

Pour oil into the gearbox.

Fill with coolant and bleed air from it.

Install the front wheels and secure them with bolts, tightening them to a torque of 90 Nm.

Carry out programming of the engine control system computer.