A burnt or defective cylinder head gasket is determined by the following signs:

- to reduce engine power;

- to reduce the level of coolant - white steam comes out of the exhaust pipe;

- to reduce the level of engine oil;

- by the presence of coolant in the engine oil: the oil turns gray and foams. At the same time, the oil level rises;

- by the presence of engine oil in the coolant;

- by intensive release of bubbles from the coolant;

- to reduce compression in two adjacent engine cylinders.

Removing

TU3JP engine

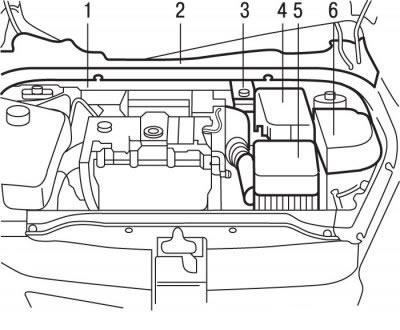

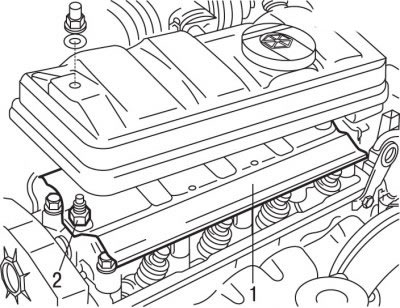

Pic. 3.1. Location of units and assemblies in the engine compartment with the TU3JP engine: 1 - plastic cross member of the amplifier; 2 - plastic windshield deflector; 3 - supply tank with brake fluid; 4 - battery; 4 - air filter with air pipe and resonator; 6 - decorative cover of the fuse box

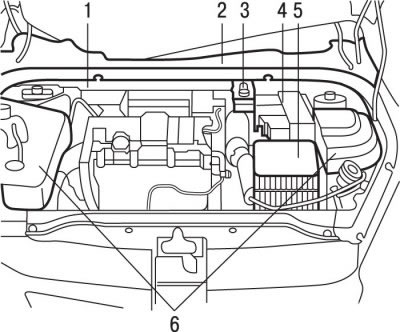

Pic. 3.2. Location of units and assemblies in the engine compartment with the TU5JP4 engine: 1 - plastic cross member of the amplifier; 2 - plastic windshield deflector; 3 - supply tank with brake fluid, 4 - battery; 5 - air filter with air pipe and resonator; 6 - decorative cover of the fuse block

Remove and move aside the supply tank 3 (see fig. 3.1, 3.2) with brake fluid.

Remove the wiper arms.

Attention! When installing the block head, you must use new mounting bolts. All clamps and clamps that will be damaged or cut during removal must be replaced with new ones when installing the head of the block. When replacing the block head, fill the cooling system with fresh coolant. Before removal of a head of the block of cylinders be convinced that all hoses, pipelines and electric sockets are disconnected from it. Turn off the ignition and disconnect the wire «masses» from the battery.

Remove plastic windshield deflector 2.

Remove the plastic cross member of the booster 1.

Remove the air filter assembly, air pipe and resonator 5.

Remove drive attachments.

Protect the lower stop of the front of the windshield with a piece of door seal.

Remove the clamps, disconnect and set aside the connectors and wiring harnesses passing near the cylinder head.

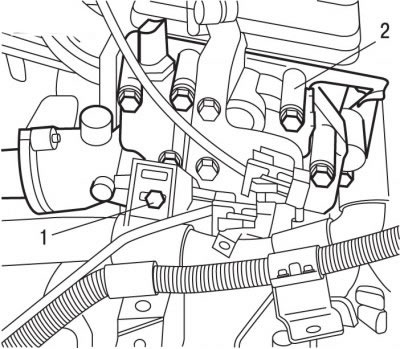

Pic. 3.9. Bolt location (1) attaching the wiring harness to the block (2) coolant outlet

Remove bolt 1 (pic. 3.9) wiring harness support, and move the wiring harness away from the coolant outlet unit 2.

Disconnect the pipes from the heater core.

Using the special tool, remove the fuel from the fuel rail.

Release the snap fasteners and disconnect the fuel supply pipes adjacent to the cylinder head.

Using special tools, fix the camshaft and flywheel.

Remove a reception pipe of system of release of the fulfilled gases.

Remove the toothed belt.

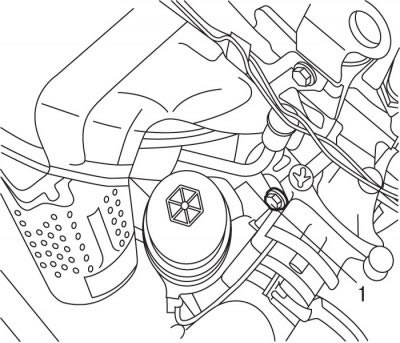

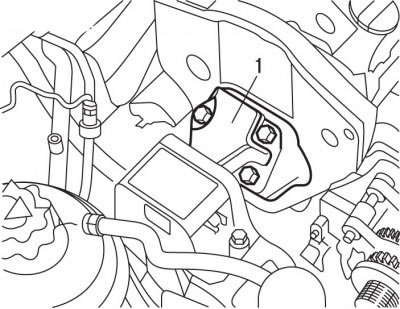

Pic. 3.10. Bolt location (1) fixing the oil level indicator tube

Remove bolt 1 (pic. 3.10) fixing the oil level indicator tube and remove the upper part of the tube.

Turn out nuts and remove a cover of a head of the block of cylinders.

Pic. 3.11. Spacer Location (1) and deflector (2) under the cylinder head cover

Remove spacers 1 (pic. 3.11) and deflector 2.

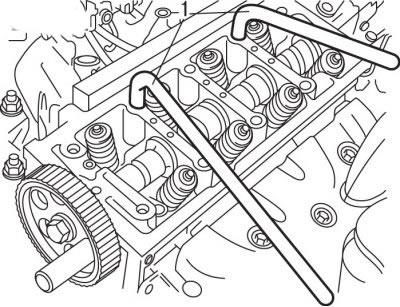

Pic. 3.12. Using Keys (1) to remove the cylinder head

In the reverse order of tightening, in a spiral, starting with the outer bolt, gradually loosen and then completely unscrew the cylinder head bolts (pic. 3.12).

Remove the cylinder head bolts.

Remove the rocker bracket.

Install the levers in the holes of the cylinder head (pic. 3.12) and, by pressing them, separate the head from the cylinder block.

Remove the cylinder head and place it on a soft base.

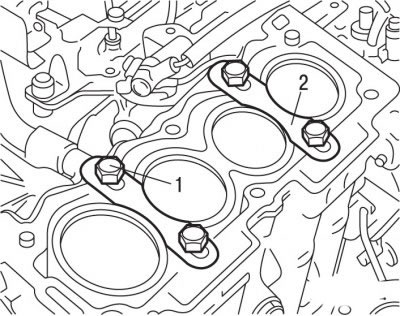

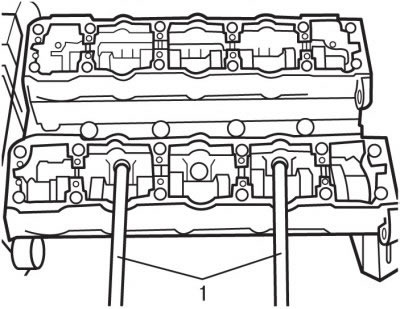

Pic. 3.13. Installing clamps (2) and bolts (1) their mountings on the cylinder block of the TU3JP engine made of aluminum alloy

On the aluminum alloy engine block TU3JP, install on the clamps 2 (pic. 3.13) to fix the cylinder liners and fix them with bolts 1.

Engine TU5JP4

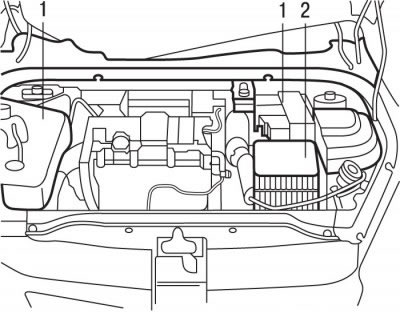

Pic. 3.14. Location of decorative covers (1) and lids (2) air filter with air pipe and resonator in the engine compartment with TU5JP4 engine

Remove decorative covers 1 (pic. 3.14).

Remove the air filter assembly, air pipe and resonator 2.

Disconnect the terminals from the battery.

Drain the coolant from the engine cooling system.

Remove the accessory drive belt.

Remove the pulley from the crankshaft.

Support the power unit by placing a stand under the engine.

Pic. 3.15. Location of the right support (1) engine

Remove the right support 1 (pic. 3.15) assembled engine.

Remove the upper and lower toothed belt covers.

Remove the upper part of the oil level indicator tube.

Remove the catalytic converter.

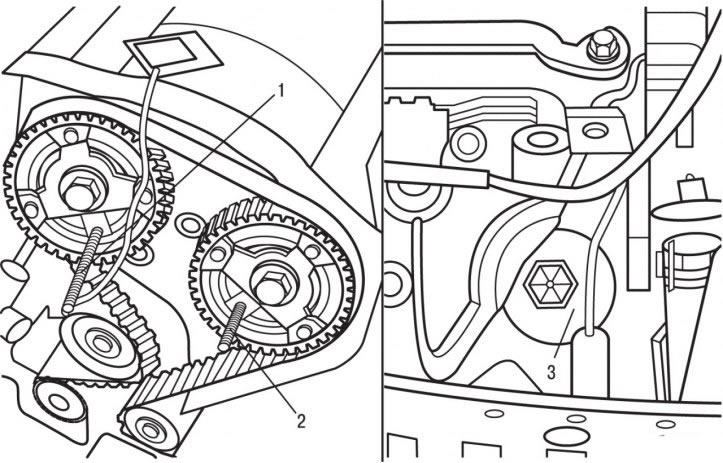

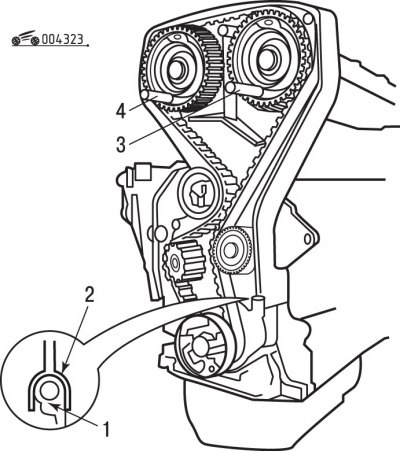

Pic. 3.16. Installation locations of special devices for fixing intake camshafts (1) and graduation (2) valves and flywheel (3)

Fix the intake and exhaust camshafts and the flywheel with special tools (pic. 3.16).

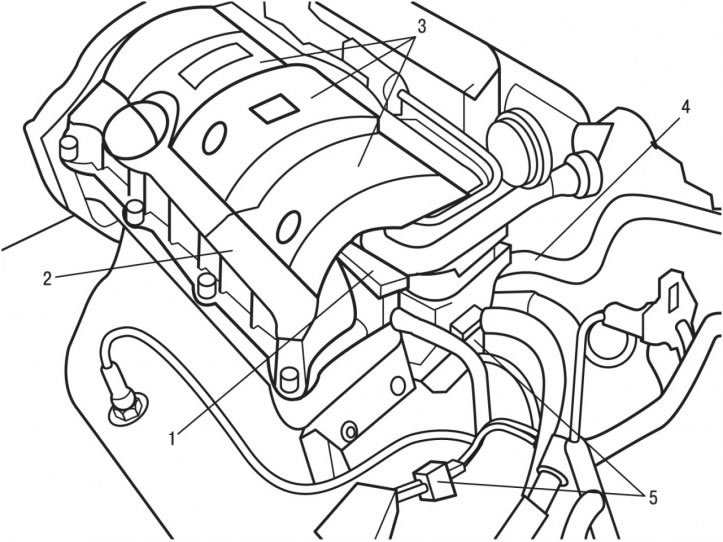

Pic. 3.17. Location of compact ignition coils: 1 - block of compact ignition coils; 2 - cover; cylinder heads; 3 - decorative cover; 4 - tubes of the heat exchanger of the air conditioning system; 5 - pin connectors

Remove decorative cover 3 (pic. 3.17) and compact ignition coil unit 1.

In the reverse order of tightening, in a spiral, starting with the outer bolt, gradually loosen and then completely unscrew the mounting bolts of each cylinder head, as when tightening the bolts.

Remove cover 2 of the cylinder head.

Disconnect the heat exchanger tube of the air conditioning system.

Release the clamps and disconnect the connectors 5.

Using a special pump, relieve pressure and remove fuel from the fuel rail.

Disconnect the intake manifold pressure sensor, fuel supply and return pipes and the clutch cable from the air pipe.

Pic. 3.18. Bolt location (1) from the inside of the cylinder heads

Sequentially, starting from the outside, in a spiral, unscrew the bolts located on the inside of the cylinder heads 1 (pic. 3.18).

Remove the mounting bolts for each cylinder head.

Pic. 3.19. Leverage (1) for separating the head from the cylinder block of the TU5JP4 engine

Install the levers 1 into the holes of the cylinder head (pic. 3.19) and by pressing them, separate the heads from the cylinder block.

Remove the cylinder head and place it on a soft base.

Preparing the head for installation

The mating surfaces of the head and cylinder block must be perfectly clean. Use a hard plastic or wooden scraper to clean them. Be careful when cleaning as aluminum alloy is very easy to damage. Make sure that carbon deposits do not get into the channels of the lubrication and cooling system. This is especially important for the lubrication system, as deposits can block the oil supply to engine parts. Clean channels if necessary.

Check the mating surfaces of the head and cylinder block: they should not have notches, deep scratches and other damage. Small defects can be eliminated by machining. In case of significant defects, the parts must be replaced.

Pic. 3.20. Measuring the flatness of the mating surface of the cylinder head

Using a metal ruler and feeler gauge, check the flatness of the mating surfaces (pic. 3.20).

If the flatness deviation exceeds 0.05 mm, the head must be reground. The height of the cylinder head of the TU3JP engine after machining must be at least 111.00 mm.

Clean the threads of the cylinder head bolt holes in the block using an M10xM150 tap.

Clean the bolt holes in the block. Screwing a bolt into an oil-filled hole can rupture the block due to hydraulic pressure.

Before reusing the bolts, measure the length of the bolts to the base of the head, which should be 176.5mm for the TU3JP engine and 122.6mm for the TU5JP4 engine.

Make sure the camshaft rotates freely in the bearings.

Installation

TU3JP engine

On the cylinder block of the TU3JP engine made of aluminum alloy, unscrew the bolts and remove the clamps 2 (see fig. 3.13).

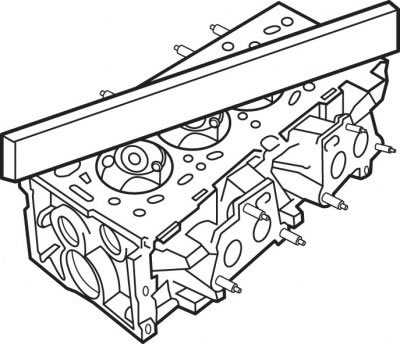

Pic. 3.21. Arrangement of guide sleeves (1) in the cylinder block of the TU3JP engine

Check that the guide bushings 1 (pic. 3.21) installed in the cylinder block.

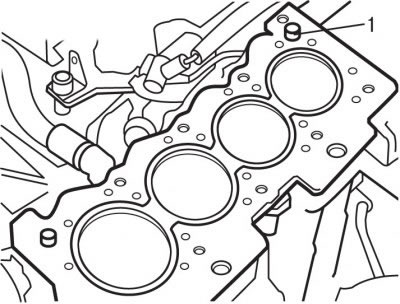

Remove a new cylinder head gasket from the packaging immediately before installation.

Install the gasket on the guide bushings, while the inscription «Oben» should point towards the head.

Install the cylinder head with the camshaft timing belt pulley fixed.

Install the rocker arm mounting rail.

Coat the threads of the cylinder head bolts with a thin coat of molybdenum based grease, insert the bolts and hand-tighten.

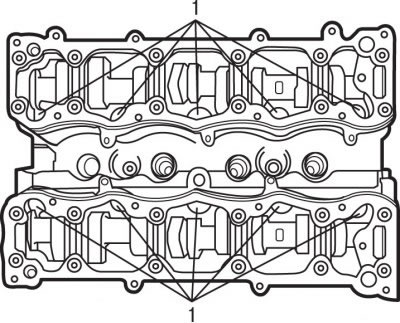

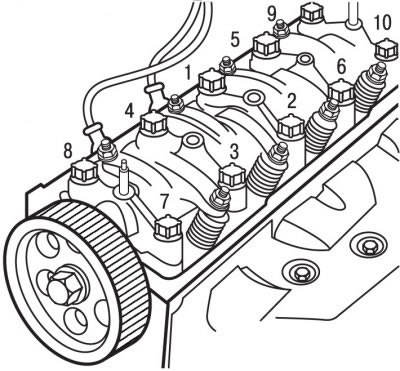

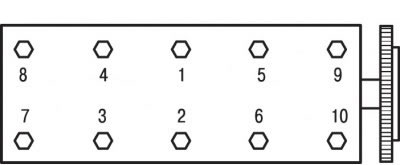

Pic. 3.22. The sequence of tightening the cylinder head bolts on the TU3JP engine

In the sequence shown in fig. 3.22, tighten the cylinder head bolts in two stages:

- 1st - tighten with a torque of 20 Nm;

- 2nd - tighten by an angle of 240°.

In the future, additional tightening of the cylinder head bolts is not required.

Install the timing belt drive of the gas distribution mechanism.

Install the accessory drive belt.

Adjust rockers.

Fill with coolant and bleed air from it.

Further installation of the engine is carried out in the reverse order of removal.

Engine TU5JP4

Check that the guide bushings 1 (see fig. 3.21) installed in the cylinder block.

Remove a new cylinder head gasket from the packaging immediately before installation.

Install the gasket on the guide bushings, while the inscription «Oben» should point towards the head.

Install the cylinder heads with the camshaft timing belt pulleys fixed in position.

Pic. 3.23. When installing the cylinder head, the camshaft timing belt pulleys must be fixed in a certain position with special tools (3 and 4), and the stiffener (2) at the bottom of the toothed belt housing must fit snugly into the holder (1) seals

Install stiffener 2 (pic. 3.23) at the bottom of the toothed belt housing so that it fits snugly into the seal holder 1.

Coat the threads of the cylinder head bolts with a thin coat of molybdenum based grease, insert the bolts and hand-tighten.

Pic. 3.24. The sequence of tightening the cylinder head bolts on the TU5JP4 engine

In the sequence shown in fig. 3.24, tighten the cylinder head bolts in two steps:

- 1st - tighten with a torque of 20 Nm;

- 2nd - tighten by an angle of 260°.

Fill the spaces under the hydraulic valve lifters with fresh engine oil.

Install the cylinder head covers, having cleaned the gaskets and the surfaces on which they are installed. The head caps are equipped with composite gaskets that can be reused. Minor damage to gaskets can be partially repaired with the special AUTOJOINTOR sealant.

Further installation of the cylinder head is carried out in the reverse order of removal.

Connect the battery.

Fill with coolant and bleed air from it.

Carry out the initialization operation of the engine management system computer.