TU3JP engine

Removing

Turn off the ignition and disconnect the wire «masses» from the battery.

Drain the coolant from the engine cooling system.

Remove the wiper blades.

Remove the plastic windshield deflector.

Remove the plastic cross member of the windshield.

Remove the accessory drive belt.

Air filter and air intake pipe.

Remove the decorative battery cover.

Remove the left front wheel arch mudguard.

Remove the battery support bolt from under the left front wheel arch.

Remove the battery.

Remove the battery support.

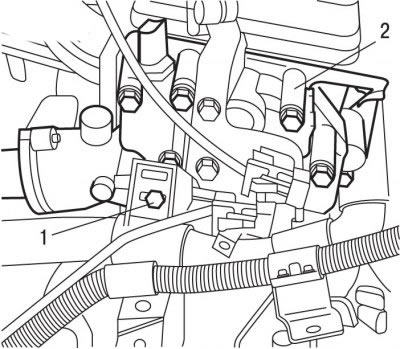

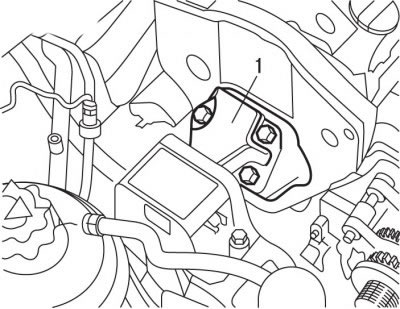

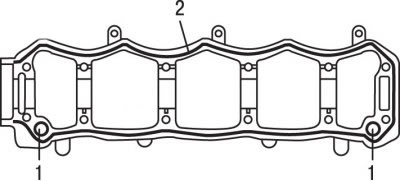

Pic. 3.9. Bolt location (1) attaching the wiring harness to the block (2) coolant outlet

Remove bolt 1 (see fig. 3.9) wire harness support, and move the wire harness away from the coolant outlet assembly.

Disconnect the wiring harnesses going to the coolant outlet block.

Turn out bolts and remove the block of an exit of a cooling liquid.

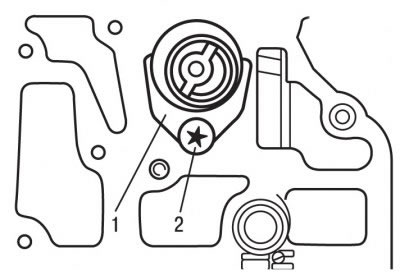

Pic. 3.25. Bolt location (2) plate mounting (1) axial fixation of the camshaft

Remove bolt 2 (pic. 3.25) and remove the plate of axial fixation 1 of the camshaft.

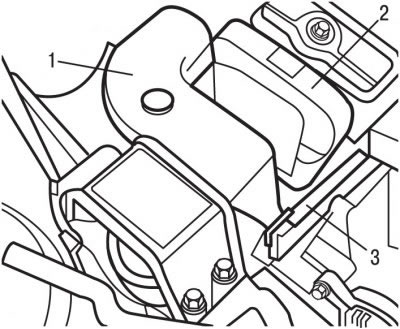

Pic. 3.26. Location of the right support (1), casing (2) toothed belt and angular reinforcement (3) supports

Remove the right support 1 (pic. 3.26) engine and corner amplifier 3 supports.

Remove casing 2 toothed belt.

Remove the toothed belt.

Attention! Protect the lower stop of the front of the windshield with a piece of door seal.

Support the engine with a hoist with claws.

Using a special tool, secure the camshaft pulley from turning and unscrew the pulley mounting bolt.

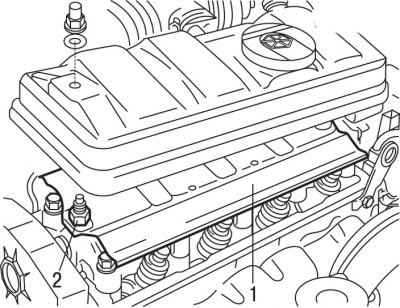

Turn out nuts and remove a cover of a head of the block of cylinders.

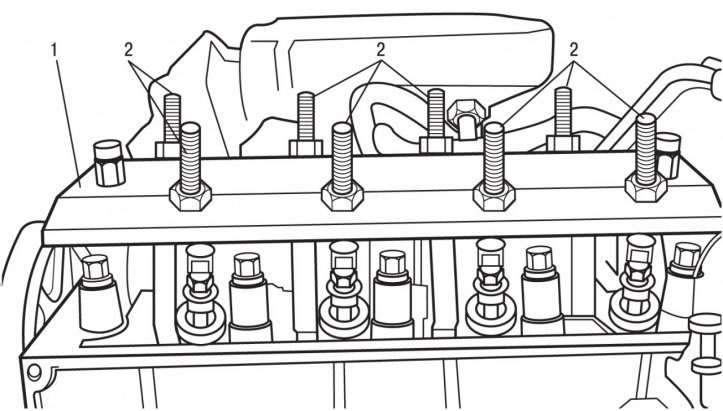

Pic. 3.11. Spacer location (1) and deflector (2) under the cylinder head cover

Remove spacers 1 (see fig. 3.11) and deflector 2.

Turning the crankshaft of the engine in the direction of working rotation, set the piston of the 1st cylinder to TDC. To do this, fix the flywheel from turning with a special tool and then remove the tool.

Turn the engine crankshaft 1/4 turn in the opposite direction.

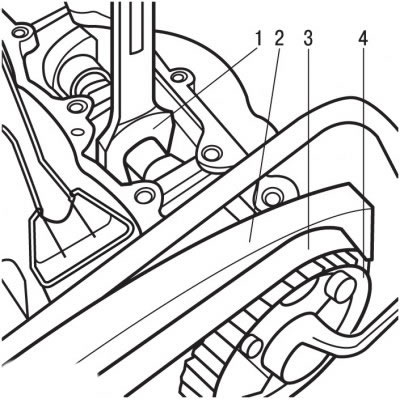

Pic. 3.27. Base plate location (1) rocker arms and bolts (2) to move the cams away from the camshaft

Install the rocker arm support plate 1 on the cylinder head (pic. 3.27), observing the correct installation direction in relation to the timing gear drive.

Tighten the bolts 2, while all the cams should move away from the camshaft.

Attention! Tighten bolts 2 just enough to release the cams, but do not bring the valves into contact with the pistons.

Remove the camshaft seal.

Remove the camshaft.

Installation

Apply a light coat of MOLYDAL GB SP 370G to the bearing journals and camshaft lobes.

Install the camshaft to the cylinder head.

Install axial locking plates 1 (see fig. 3.25) camshaft and secure it with bolt 2, tightening it to 15 Nm.

Install the camshaft O-ring with a tubular mandrel of the appropriate diameter.

Further installation is carried out in the reverse order of removal, taking into account the following.

Clean the mating surfaces of the cylinder head and coolant outlet block.

Lubricate the mating surface of the cylinder head with the coolant outlet block with silicone paste.

Install the toothed belt.

Install the accessory drive belt.

Pour coolant into the engine cooling system.

Engine TU5JP4

Removing

Turn off the ignition and disconnect the wire «masses» from the battery.

Remove the protective cover from the right side of the engine compartment.

Remove the accessory drive belt.

Remove the pulley from the crankshaft.

Support the power unit by placing a stand under the engine.

Pic. 3.15. Location of the right support (1) engine

Remove the right support 1 (see fig. 3.15) assembled engine.

Remove the upper and lower toothed belt covers.

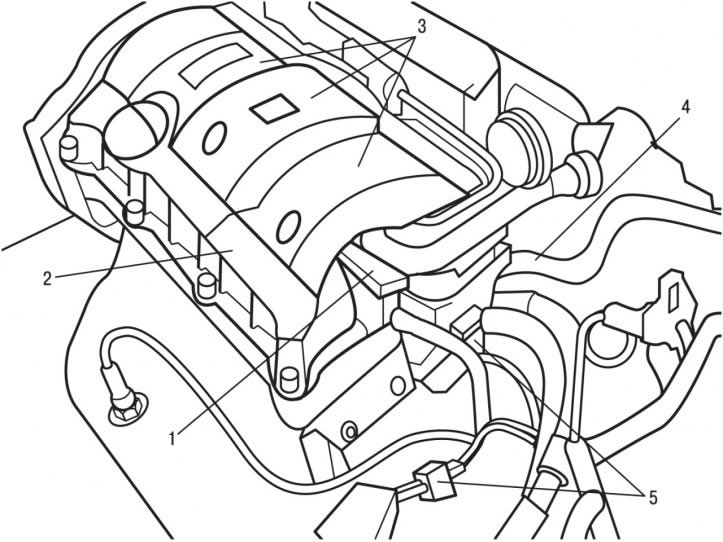

Pic. 3.17. Location of compact ignition coils: 1 - block of compact ignition coils; 2 - cover; cylinder heads; 3 - decorative cover; 4 - tubes of the heat exchanger of the air conditioning system; 5 - pin connectors

Remove cover 2 (see fig. 3.17) cylinder heads.

Turning the crankshaft of the engine in the direction of working rotation, set the piston of the 1st cylinder to TDC. To do this, use a special tool to secure the flywheel from turning and then remove the tool.

Turn the engine crankshaft 1/4 turn in the opposite direction.

In a spiral, starting with the outer bolt, remove the bolts securing each cylinder head cover.

Remove the cylinder head covers.

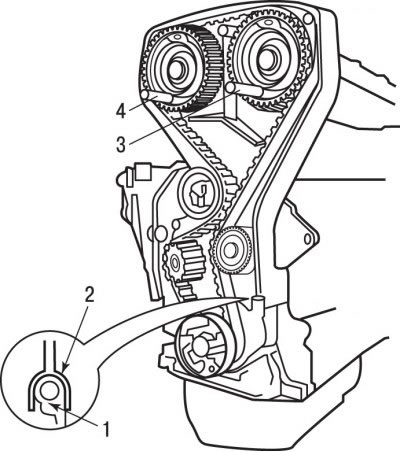

Pic. 3.28. Removing the camshaft timing belt pulley hub bolt: 1 - a wrench mounted on the flats of the camshaft; 2 - rear casing of the toothed belt; 3 - toothed belt; 4 - toothed belt pulley

Fixing with one wrench 1 (pic. 3.28) behind the flats of the camshaft from turning, with the second key, unscrew the bolt securing the hub of the toothed belt pulley.

Remove toothed belt 3.

Remove the toothed belt pulley 4 with the hub from the camshaft.

Remove a back casing 2 gear belts.

Remove the camshaft seals.

Gradually in a spiral, starting with the outer bolt, loosen and then unscrew the bolts securing the camshaft bearing housings so as to obtain a gap of several millimeters between the connecting planes.

Remove the camshafts from the bushings by tapping them with a wooden mallet from the side of the pulley.

Completely turn out bolts and remove cases of bearings of camshafts.

Remove camshafts.

If pushers will be removed, first mark their location for subsequent installation in their places.

Using a vacuum suction cup of the valve lapping type, remove the tappets from the cylinder head.

Suck out the oil from the threaded holes for attaching the camshaft bearing housings.

Installation

Reinstall the pushrods after lubricating them with MOLYDAL GB SP 370G oil.

Check for free rotation of the tappets in the cylinder head.

Apply a light coat of MOLYDAL GB SP 370G to the bearing journals and camshaft lobes.

Install the camshafts in the cylinder head by turning the locating groove of the intake valve shaft to the position «at 7 o'clock», and the exhaust valve shaft to the position «for 8 hours».

Thoroughly clean the mating surfaces of the cylinder head and camshaft bearing housing.

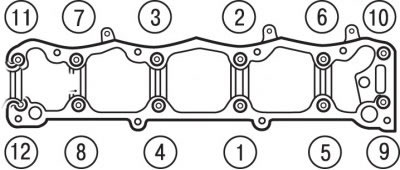

Pic. 3.29. Locations of dowel pins (1) and applying a layer of sealant (2) on the camshaft bearing housing

Make sure that the dowel pins 1 (pic. 3.29) are in place.

Apply a coat of 2 AUTOJOINT OR sealant all around on the camshaft bearing housing.

Install the camshaft bearing housings.

Pic. 3.30. The sequence of tightening the bolts of the camshaft bearing housings

In the sequence shown in fig. 3.30, tighten the bolts securing the camshaft bearing housings to a torque of 2 Nm, and then tighten to a torque of 8 Nm.

Install the camshaft O-rings with a tubular sender of the appropriate diameter.

Pic. 3.23. When installing the cylinder head, the camshaft timing belt pulleys must be fixed in a certain position with special tools (3 and 4), and the stiffener (2) at the bottom of the toothed belt housing must fit snugly into the holder (1) seals

Establish a back casing of a gear belt. Install stiffener 2 (see fig. 3.23) at the bottom of the toothed belt housing so that it fits snugly into the seal holder 1.

Install the toothed belt pulleys on the camshafts.

Fixing with one wrench 1 (see fig. 3.28) behind the flats of the camshaft from turning, with the second wrench, tighten the bolt of the toothed belt pulley hub to 80 Nm.

Make sure the camshaft pulley rotates freely on the hub.

Secure the camshaft pulleys and flywheel with special tools from turning.

Install the toothed belt and adjust its tension.

Install the toothed belt guards.

Clean the mating surfaces of the cylinder head covers and install them in place.

The head caps are equipped with composite gaskets that can be reused. Minor damage to the gasket can be partially repaired with a special sealant SILICONE CATEGORIE 2.

Further installation is carried out in the reverse order of removal.