- remove the gearbox;

- mark with a marker or paint the position of the clutch assembly in relation to the flywheel;

- using a special tool or a screwdriver, use the teeth of the flywheel ring gear to block it from turning;

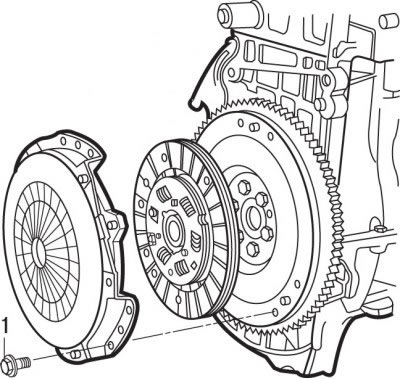

Pic. 5.9. Bolt location (1) clutch mounting

- gradually loosen bolts 1 diagonally (pic. 5.9) fastening the clutch assembly by turning each bolt half a turn until the spring action stops and the bolts can be unscrewed by hand;

- remove the pressure plate, while supporting the driven disc so that it does not fall out;

- clean the clutch release bearing from dirt, but do not use solvents;

- wipe the flywheel with gasoline.

To check the condition of the clutch disc:

- check the condition of the clutch pressure plate. Traces of wear at the ends of the pressure spring should be no more than 0.3 mm;

- check the reliability of the spring connection between the pressure plate and the clutch cover. Scratches and missing or damaged rivets are not allowed;

- check the pressure plate for cracks, burn marks and surface wear;

- Using a steel ruler and a feeler blade, check the flatness of the working surface of the pressure plate. The flatness of the pressure plate must not exceed 0.2 mm;

- check the condition of the friction surface of the flywheel for cracks, burns and surface wear;

- check the condition of the friction linings of the clutch driven disk and if there are traces of oil or mechanical damage on them, replace the driven disk;

- Measure the thickness of the clutch disc linings. If their thickness is less than acceptable or if the rivet heads are close to the working surface, replace them or the clutch disc;

- check the condition of the release bearing, which should rotate easily, evenly and silently and there should be no play in it. The working surface of the bearing acting on the pressure spring must be smooth, without cracks, local corrosion or wear;

- a faulty clutch release bearing can be determined without removing it from the vehicle, for which it is necessary to press the clutch pedal while the engine is running. If there is noise when you press the clutch pedal, then the clutch release bearing is defective and must be replaced;

- If oil is present in the clutch housing, the crankshaft rear O-ring must be replaced.

To install the clutch disc:

- lubricate the splines in the hub of the driven disk with a thin layer of special grease based on molybdenum disulphide;

Note. When installing a new driven disc or clutch pressure plate, remove the anti-corrosion protection from them.

- install the driven disk on the flywheel so that the spring of the shock-absorbing disk hub is directed outward, towards the gearbox;

- when reinstalling a previously removed clutch pressure plate, check that the marks applied before removal are aligned;

Attention! The lubrication layer must be thin and even, otherwise, during clutch operation, excess lubricant will be thrown onto the working surfaces of the clutch, which can disrupt its operation. When installing the driven disc, make sure that even small amounts of oil do not get on its friction linings. Therefore, before installation, wipe the mating surface of the flywheel and the surface of the pressure plate with a clean rag, install the driven disk with clean hands.

- tighten the clutch mounting bolts so that the clutch disc is pressed, but at the same time can still move to the sides;

- using a special mandrel 0213/0214 or an old transmission input shaft, center the clutch disc on the flywheel;

- after centering the driven disk, tighten the bolts securing the clutch cover gradually diagonally to 20 Nm;

- remove the mandrel from the driven disk;

- lubricate the spline of the gearbox input shaft, the clutch release bearing guide bushing and the fork tips with a thin layer of MOLYKOTE BR2 PLUS special grease;

- install the clutch release bearing;

- install the gearbox.