- remove the air filter and the air pipe connecting the air filter and the engine;

- remove the decorative engine cover;

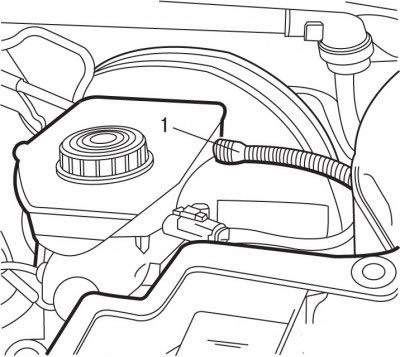

- remove the cap from the reservoir with brake fluid and pump out the fluid from the reservoir with a syringe;

- open the valve to remove air from the hydraulic system and drain the brake fluid from it;

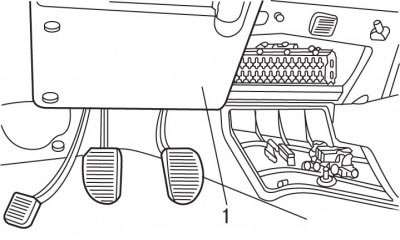

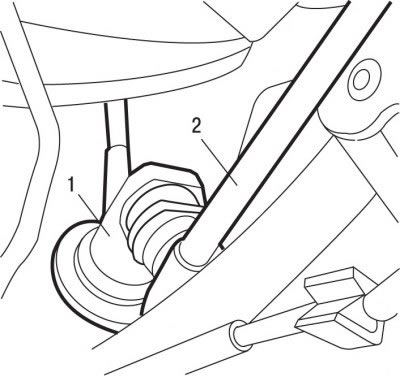

Pic. 5.1. Bottom left trim panel above the pedal box (1)

- in the car, remove the lower left decorative panel 1 (pic. 5.1), located above the pedal block;

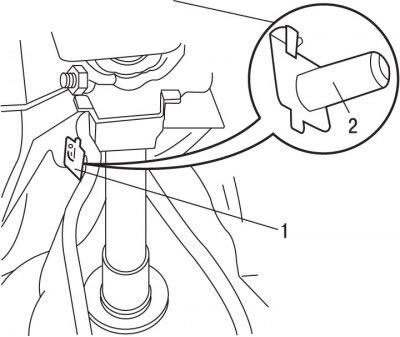

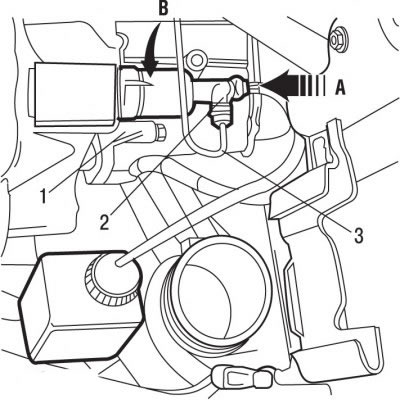

Pic. 5.2. Axis location (1) and plastic retainer (2)

- remove axle 1 (pic. 5.2), supported by plastic retainer 2;

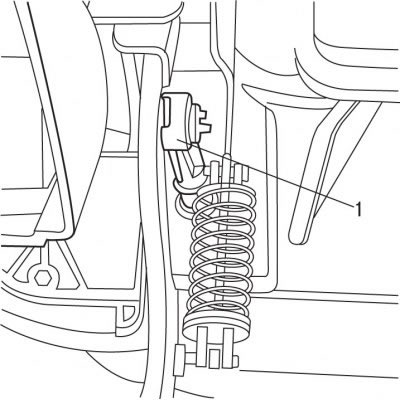

Pic. 5.3. Push rod location (1)

- remove push rod 1 (pic. 5.3);

Pic. 5.4. The place of connection of the hose to the compensatory tank with brake fluid

- disconnect hose 1 (pic. 5.4) from the compensation tank with brake fluid and close it with a suitable stopper;

- for vehicles with MA gearbox, do the following:

- remove the main brake cylinder and vacuum brake booster;

- for other vehicles, do the following:

Pic. 5.5. Latch location (1) and tubes (2)

- release latch 1 (pic. 5.5) and disconnect tube 2;

- turn the clutch master cylinder a quarter of a turn clockwise and remove it;

Pic. 5.6. Clutch slave cylinder: 1 - clutch slave cylinder; 2 - latch; 3 - tube; A and B - directions of movement and rotation of the clutch slave cylinder

- without removing, release latch 2 (pic. 5.6) attaching the clutch tube to the clutch slave cylinder;

- disconnect tube 3 from the clutch slave cylinder and take it aside;

- disconnect the clutch slave cylinder 1 from the hydraulic circuit (pressing in the direction of arrow A and turning counterclockwise in direction of arrow B) and take it off.

To install a hydraulic clutch actuator:

- apply a thin coat of ESSO NORVA 275 grease to the pushrod head 1 (see fig. 5.3);

- apply a light coat of MOLYKOTE BR2 PLUS to the clutch slave cylinder tip on the clutch side;

- further installation is carried out in the reverse order of removal, taking into account the following;

- remove air from the hydraulic circuits of the brake system and clutch;

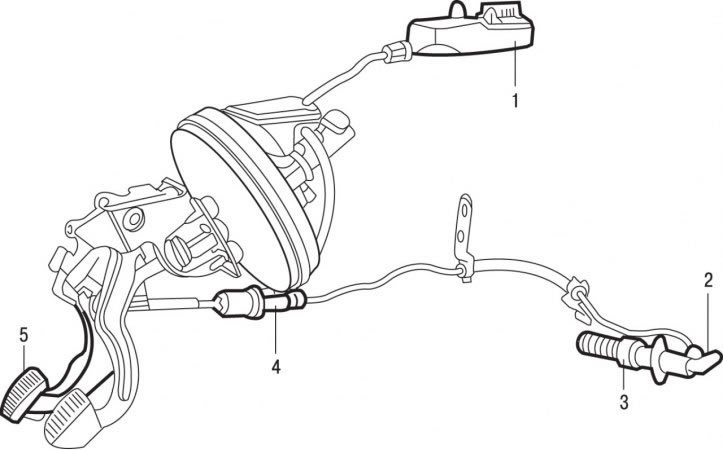

Pic. 5.7. Clutch hydraulic circuit: 1 - filling tank; 2 - fitting for removing air; 3 - clutch slave cylinder; 4 - the main cylinder of the hydraulic clutch drive; 5 - clutch pedal

- Pour brake fluid into filler tank 1 (pic. 5.7) brake system up to the mark «Max»;

Warning!

- 1. The brake fluid used in the hydraulic clutch is poisonous, so if it comes into contact with the skin, immediately wash the area with plenty of water. If the liquid gets into the eyes or inside the body, you should immediately consult a doctor. Some liquids tend to be highly flammable and can ignite even from contact with hot vehicle components. In addition, the fluid used in the hydraulic drive dissolves paint and plastic, so if fluid gets on the car's paintwork, wash it with plenty of water. Since this liquid is hygroscopic (absorbs moisture from the air), it is not recommended to use liquid that has been stored for a long time in an open container.

- 2. Any hydraulic system works properly if air is removed from it. During bleeding, add only clean fluid recommended by the manufacturer. Never reuse fluid that has leaked from the hydraulic clutch. If fluids of different brands are accidentally mixed in the hydraulic system, remove the fluid from it and flush it with a clean fluid of the required brand. If hydraulic fluid leaks continuously or air enters the hydraulic system, determine the cause and location of the leak and repair the damage. Use only approved and recommended brands of DOT4 brake fluids. Do not use an automatic bleeder (in this case, the formation of air bubbles in the liquid filling the circuit is possible).

- rock the reservoir from side to side to remove air pockets. You can also press the clutch pedal about 10 times until you need to top up the brake fluid reservoir;

- add brake fluid to the brake system filler tank up to the mark «Max»;

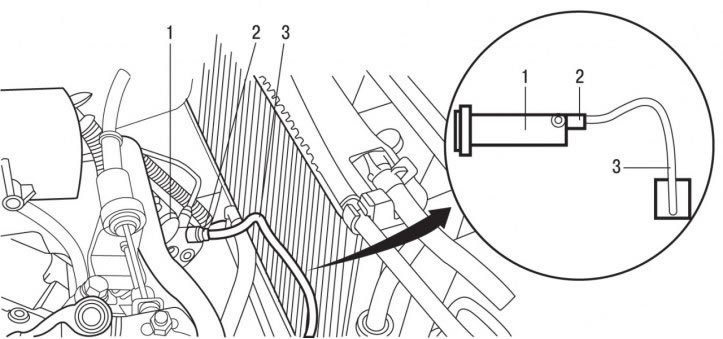

Pic. 5.8. Connecting a transparent tube when bleeding from a hydraulic clutch actuator with a type MA gearbox: 1 - clutch slave cylinder; 2 - fitting for removing air; 3 - transparent tube

- connect a transparent tube to fitting 2 (pic. 5.8) to remove air, lower the other end of the tube into a glass vessel partially filled with brake fluid and located below the working cylinder 1 of the hydraulic clutch drive. Bend the transparent tube so that you get a siphon pointing up;

- remove the stopper from the compensation tank with brake fluid;

- sharply press the clutch pedal several times at intervals of 2-3 s. Unscrew the union 2 for removal of air on half-turn at the pressed pedal. Continuing to press the pedal, force the liquid in the system together with air through a transparent tube into a glass vessel. After the pedal reaches the extreme forward position and the displacement of liquid through the transparent tube stops, screw the air bleeder in until it stops;

- lift the clutch pedal to the highest position by hand;

- repeat these operations until the air exits from the transparent tube stops;

- while holding the pedal down, tighten the fitting to 7.5 Nm and remove the transparent tube;

- wipe the bleed valve and install the protective cap;

- add brake fluid to the brake system filler tank up to the mark «Max»;

- screw the plug on the brake system filler tank;

- before starting the engine 40 times quickly (2 strokes per second) press and release the clutch pedal;

- check that the clutch starts to engage when the clutch pedal is released by 35 mm or more. Otherwise, repeat the operations to remove air from the clutch hydraulic system.