- turn off the ignition and disconnect the wire «masses» from the storage battery;

- remove the pipes of the crankcase ventilation system;

- remove the air filter;

- disconnect and remove the branch pipe at the outlet of the air filter;

- remove the resonator;

- remove the decorative battery cover;

- remove the mudguard of the left front wheel arch;

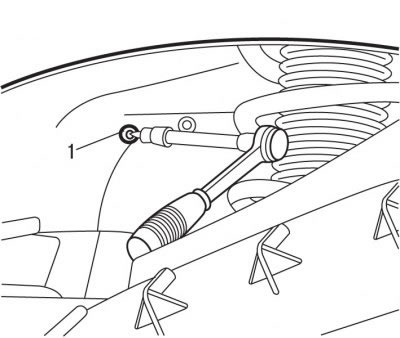

Pic. 5.20. Removing a bolt (1) battery support mountings

- from under the arch of the left front wheel, unscrew the bolt 1 (pic. 5.20) fastening of a support of the accumulator battery;

- remove the battery;

- remove the battery support;

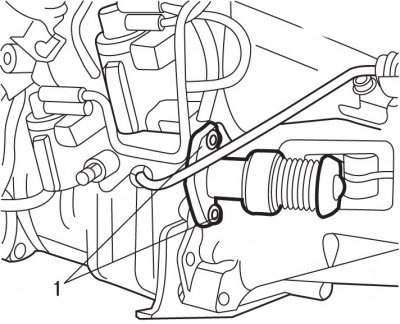

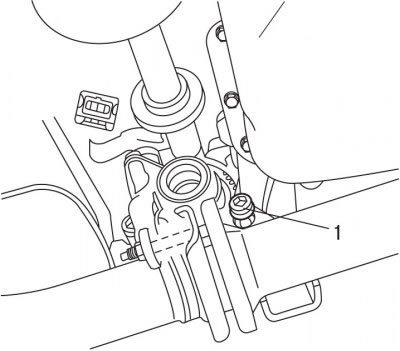

Pic. 5.21. Bolt location (1) clutch slave cylinder mountings

- remove bolts 4 (pic. 5.21), remove the clutch slave cylinder 1 and attach it to the body with a soft wire;

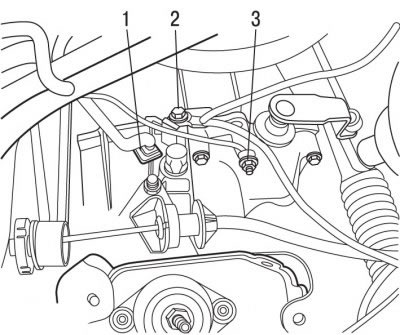

Pic. 5.22. Electrical connector mounting location: 1 - bolt; 2 - nut; 3 - electrical connector

- remove bolt 1 (pic. 5.22), nut 2 and disconnect electrical connector 3;

Pic. 5.23. Electrical connector location (1) and bolts (2)

- disconnect electrical connector 1 (pic. 5.23), turn out bolts 2;

- unscrew the lower bolts securing the clutch housing to the cylinder block;

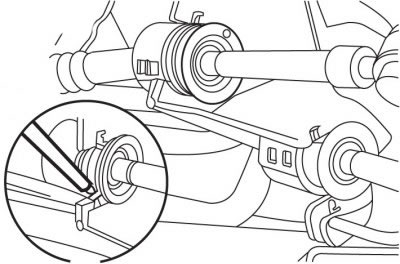

Pic. 5.24. Using a screwdriver blade to pry out the metal tabs before disengaging the transmission control rods

- use a screwdriver blade to squeeze out two metal protrusions, disconnect the gearbox control rods and take them away from the gearbox support (pic. 5.24);

- raise the car by hanging the front wheels;

- remove the drive shafts;

Pic. 5.25. Bolt location (1) above the front pipe connection of the exhaust system

- remove bolt 1 (pic. 5.25), located above the front pipe connection of the exhaust system;

- lower the car;

- remove the wiper drive mechanism;

- install a support cross member to support the power unit;

- hook the catch of the support cross member to the bracket to lift the engine;

- hook the grips of the lifting cables to the gearbox;

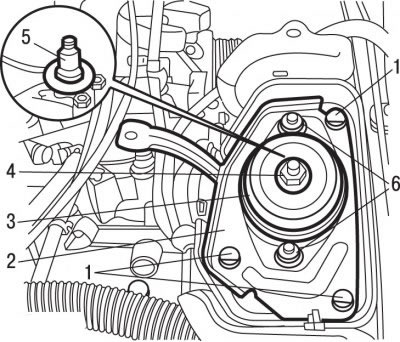

Pic. 5.13. Elastic support attachment: 1 - bolts; 2 - bracket; 3 - elastic support; 4 - nut, 65 Nm; 5 - gearbox axis; 6 - bolts, 30 Nm

- unscrew nut 4 (see fig. 5.13) fixing the gearbox suspension axle and remove it in place with a washer;

- turn out bolts 6 fastenings of a pillow;

- remove the elastic pad 3;

- turn out bolts 1 and remove an arm 2 an axis of a transmission;

- using a special bushing 0317-AB, remove the gearbox axle 5;

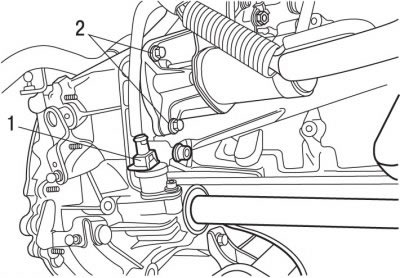

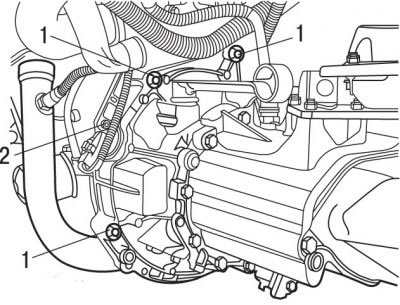

Pic. 5.26. The location of the gearbox mounting bolts (1) and supports (2) speed sensor

- unscrew the top bolts 1 (pic. 5.26) gearbox mountings;

- turn out a bolt and remove a support 2 of the gauge of frequency of rotation;

- remove the gearbox.

To install the gearbox:

- check the condition of the clutch;

- clean the splined part of the input shaft of the gearbox;

Attention! Do not apply grease to the transmission input shaft splines.

- check for oil leaks at the level of the clutch release bearing;

- check for oil leaks at the level of the rear crankshaft sealing ring;

- check the amount of wear of the friction linings of the clutch disc;

- replace the differential sealing rings, having previously lubricated the working edges of the rings;

- replace with new self-locking nuts and bolts, as well as lock washers and seals;

Attention! Make sure that guide bushings are installed in the engine block to center the gearbox.

- lubricate the guide bushing of the clutch release bearing with a thin layer of G12 special grease. The lubrication layer must be thin and uniform, otherwise, during clutch operation, excess lubricant will be thrown onto the working surfaces of the clutch, which can disrupt its operation;

- attach the gearbox to the engine;

- move the gearbox towards the engine so that the input shaft of the gearbox enters the splines of the clutch disc (to align the splines of the gearbox input shaft with the splines of the clutch disc. You may have to rotate the engine crankshaft slightly to do this. When installing the gearbox, the input shaft must not hang on the clutch disc);

- moving the gearbox forward, install the clutch housing on the guide bushings of the cylinder block;

- using special bushing 0317-AB, install axle 5 (see fig. 5.13) gearbox suspension together with a washer;

- install the bracket 2 of the gearbox axle and fix it with bolts 1;

- install elastic pad 3;

- screw in bolts 6, tightening them at this stage by hand;

- install the washer and tighten the nut 4 of the gearbox suspension axle;

- tighten bolts 6 to 30 Nm and nut 4 to 65 Nm;

Attention! Before tightening the bolts securing the elastic gasket, center the position of the power unit.

- install the clutch slave cylinder and secure it with bolts;

- press and release the clutch pedal several times until it stops;

- install drive shafts;

- pour oil into the gearbox;

- connect wire «masses» to the battery;

- initialize all computers.