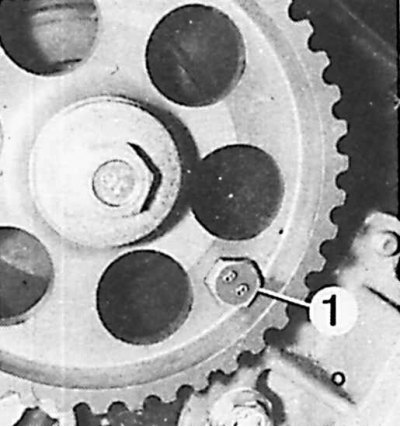

Camshaft fixing

1 - blocking bolt

The valve clearance must be adjusted only in cases of detection of increased fuel consumption, improper adjustment, replacement or finishing of valves, replacement of tappets or camshaft.

Examination

Valve clearance is checked with a cold engine.

1. On naturally aspirated engines, remove the air duct.

2. On turbocharged engines, remove the boost cooler.

3. Remove the head cover.

4. Unscrew the glow plugs.

5. Remove the right pulley and casing.

6. Check valve clearances in two steps:

- bring to the state of opening the valve of cylinder No. 4. Check the valve clearances of cylinders No.: 1 - intake, 1 - exhaust, 2 - intake, 3 - exhaust;

- bring to the state of opening the valve of cylinder No. 1. Check the valve clearances of cylinders No.: 4 - intake, 4 - exhaust, 3 - intake, 2 - exhaust.

Valve clearances (engine cold)

| Inlet valve | 0.15 mm |

| Exhaust valve | 0.30 mm |

| Tolerance | ±0.08mm |

Adjustment

1. Check the valve clearances according to the method described above and record the measured values.

2. Loosen the camshaft drive belt and remove it from the camshaft pulley.

3. Block the camshaft pulley with a special bolt and unscrew the mounting bolt.

4. Remove the pulley.

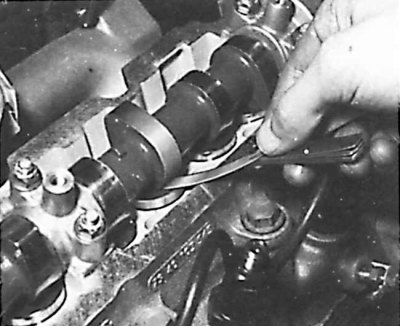

5. Remove the camshaft bearing caps and camshaft.

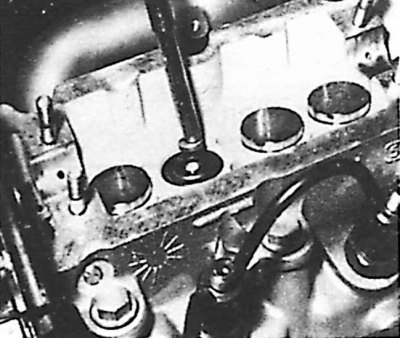

6. Remove pushers and install them in order.

7. Remove the adjusting plates and measure their thickness.

8. Determine the required thickness of the adjusting plates:

- if the measured gap is too small, then a thinner plate should be installed (see table. Example A);

- if the measured gap is too large, then a thicker plate should be installed (see table. Example B).

Attention! After replacing one of the parts of the gas distribution system or after grinding in the valves, 8 control plates with a thickness of at least 2.425 mm should be installed.

9. Establish pushers with adjusting plates of the necessary thickness.

10. Install new o-rings.

11. Install the camshaft pulley.

12. Check camshaft installation.

13. Establish and adjust a tension of a gear belt.

14. Install the distribution drive cover.

15. Install the seal, secure the cylinder head cover and other dismantled parts.

Valve clearance examples

Example A

| Required clearance | 0.15 mm (inlet) |

| Measured clearance | 0.25 mm |

| Difference | 0.10 mm |

| Installed plate thickness | 2.35mm |

| Thickness of the plate to be installed | 2.45mm |

| The resulting gap | 0.15 mm |

Example B

| Required clearance | 0.30 mm (release) |

| Measured clearance | 0.25 mm |

| Difference | -0.05mm |

| Installed plate thickness | 2.925 mm |

| Thickness of the plate to be installed | 2.875 mm |

| The resulting gap | 0.30 mm |