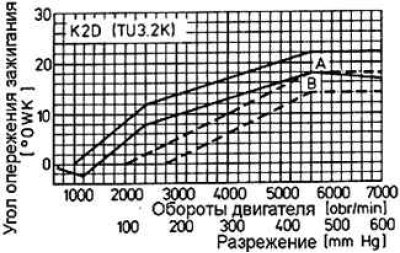

Characteristics of the ignition timing of the engine TU3.2 K

A - centrifugal regulator, B - vacuum regulator

During the test on the stand, the values \u200b\u200bshould be reduced by half.

During the test in the car, the value of the initial ignition timing should be added.

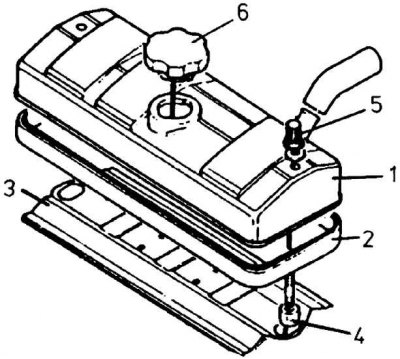

Valve cover assembly

1 - valve cover, 2 - valve cover seal, 3 - sheet casing (oil reflector), 4 - remote bushing, 5 - cover bolt, 6 - oil filler plug

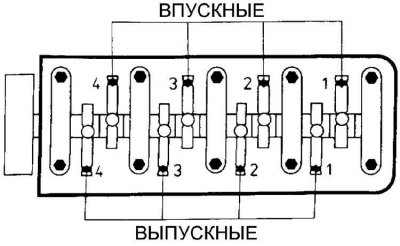

Arrangement and designation of valves of individual cylinders

Valve clearance should be checked when the engine is cold (at temperatures below 30°C). Valve clearance is checked with a feeler gauge between the end of the valve neck and the valve lever adjusting bolt. With the valve clearance properly set, the feeler gauge blade should move between the valve neck and the bolt with light force.

1. Remove valve cover.

2. Remove the valve cover seal and remove the two spacers and oil deflector.

3. Rotate the crankshaft in the direction of normal operation until the exhaust valve for that cylinder is fully open. Rotate the crankshaft using the crankshaft pulley bolt or by rotating one of the front wheels of the vehicle after lifting the front of the vehicle and engaging 4th or 5th gear.

4. With the exhaust valve fully open, check the valve clearance in the appropriate order (see table. One of the valve clearance check sequence methods).

5. If necessary, adjust the valve clearances by loosening the lock nut and screwing or unscrewing the adjusting bolt accordingly, then tighten the lock nut.

6. After adjustment, install the sheet casing in the cylinder head (oil reflector), two spacers, a new valve cover seal and valve cover, tightening the mounting bolts to 16 Nm.

One of the valve clearance check sequence methods

| Open the exhaust valve of cylinder no | Adjust clearance of the following valves | |

| 1 | intake 3 cylinder | exhaust 4 cylinder |

| 3 | intake 4 cylinder | exhaust 2 cylinder |

| 4 | intake 2 cylinder | exhaust 1 cylinder |

| 2 | intake 1 cylinder | exhaust 3 cylinder |

valve clearance (engine cold):

- intake valve - 0.20 mm

- exhaust valve - 0.40 mm

- tolerance -±0.05 mm