Examination

Models 1905 cm3 and 1998 cm3 with 16 valves

Models 1905 cm3 and 1998 cm3 with 16 valves have automatic valve clearance adjustment.

Other models

Valve clearance is checked with a feeler gauge between the cam and tappet.

Before checking the clearance, the engine must be allowed to cool for at least 2 hours with the hood open.

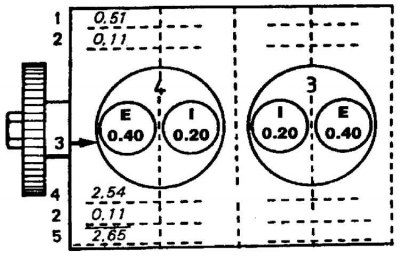

Example of calculating the thickness of the valve shim

I - inlet valve, E - exhaust valve, 1 - measured clearance, 2 - difference between 1 and 3, 3 - required clearance, 4 - installed plate thickness, 5 - new plate thickness

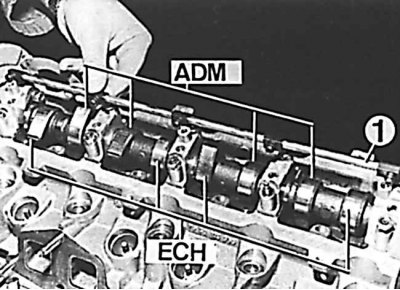

Valve arrangement

ADM - inlet valves,

ECH - exhaust valves,

1 - oil pipeline for lubrication of camshaft bearings

1. Remove the cylinder head cover.

2. Draw a diagram of the engine on paper. Show the position of each valve along with the specified valve clearance. Above each valve draw two lines to write (1) actual gap and (2) the amount of adjustment required.

3. Turn the crankshaft until the inlet valve of cylinder No. 1 is completely closed (flywheel side), i.e. the camshaft cam must point upwards. Use a feeler gauge to measure the gap between the cam and the tappet and record it on line 1.

4. Repeat the measurement for the remaining seven valves, rotating the crankshaft as necessary so that the cam in question is always pointing up.

5. Calculate the difference between each measured gap and the required gap and write it down on line 2.

6. If the measured gap does not correspond to the required, it is necessary to make an adjustment.

Valve clearance (cold engine):

- intake valve: 0.20 mm;

- exhaust valve: 0.40 mm;

- tolerance:±0.05 mm.

One of the valve clearance check sequence methods

| Open the exhaust valve of cylinder no | Adjust clearance of the following valves |

| 1 | intake 3 cyl., exhaust 4 cyl. |

| 2 | intake 4 cyl., exhaust 2 cyl. |

| 3 | intake 2 cyl., exhaust 1 cyl. |

| 4 | intake 1 cyl., exhaust 3 cyl. |

Adjustment

1. Check the valve clearance according to the above method and record the measured valve clearances.

2. Remove the camshaft drive belt.

3. Remove the camshaft bearing lubrication oil line, distributor, bearing mounting bolt No. 1 and camshaft flange.

4. Insert a steel special rod with a diameter of 10 mm (70 mm long) into the camshaft pulley and unscrew the bolt securing this pulley.

5. Unscrew the bolt under the coolant pipe bracket (coolant must not be drained) and remove the sheet casing.

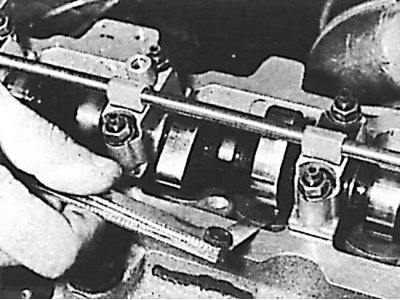

6. Unscrew the nuts securing the camshaft bearing caps in order.

7. Separate cover #1 (near the distributor) from its side seal and remove the remaining covers (caps #2 and 4 are marked).

8. Remove right side camshaft.

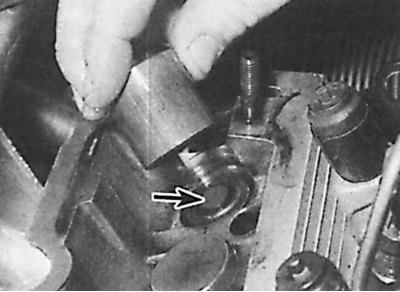

9. Remove the pushers and install them in a row in order (the pusher is shown by an arrow).

10. Remove the adjusting plates and measure their thickness.

11. Determine the required thickness of the adjusting plates:

- if the measured gap is too small, then a thinner plate should be installed, by the value recorded on line 2;

- if the measured gap is too large, then a plate of greater thickness should be installed, by the value recorded on line 2.

12. Draw three more lines in the figure below each valve.

13. On line (4) apply the measured thickness of the plates that were removed from the engine, then add or subtract the difference from the line (2), to get the required thickness of the plates, and write on the line (5).

Attention! After replacing one of the parts of the gas distribution system or after lapping the valves, install 8 adjusting plates with a thickness of at least 2.15 mm.

14. Install pushers with plates of the required thickness.

15. Install the camshaft and bearing caps. The installation order must be followed. Tighten bearing caps to 15 Nm.

16. Turn the camshaft with the pulley bolt and check the valve clearance. If an incorrect clearance is found, the adjustment must be repeated.

17. Check if the crankshaft is in the installation position of the gas distribution system.

18. Replace #1 bearing cap side seal, lubricate sealing paste on both seal faces and bottom connection.

19. Install the camshaft mounting flange.

20. Install a new camshaft seal on the drive side (tool 7.0153 E with bolt and pulley gasket).

21. Install the sheet casing without tightening the fasteners.

22. Center the casing with a rod with a diameter of 10 mm.

23. Install the camshaft pulley and insert the timing rod into the appropriate place.

24. Tighten pulley bolt to 80 Nm.

25. Screw in the cover screws.

26. Install the camshaft bearing lubrication port, distributor, cylinder head cover and connect the wires.

27. Install the camshaft drive belt.

28. Adjust ignition timing.