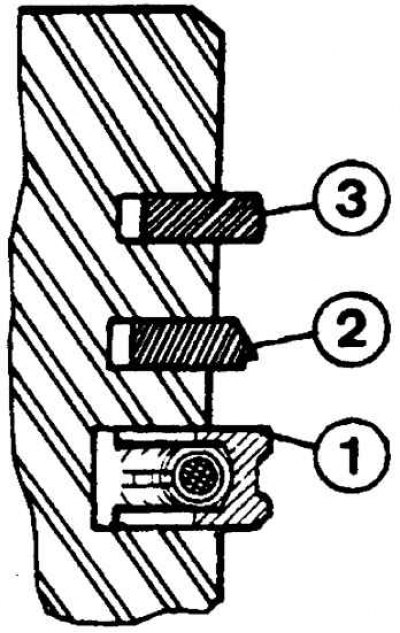

Typical piston ring placement

1 - oil scraper ring,

2 - the second sealing ring,

3 - top sealing ring

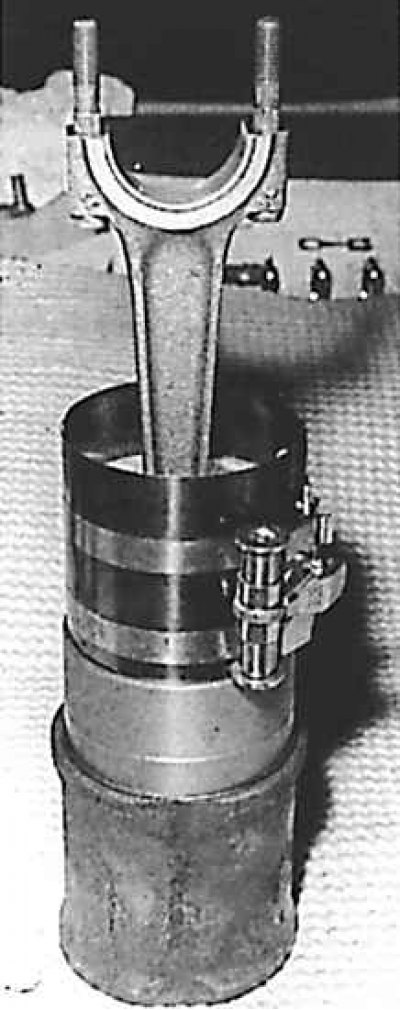

Installation of the piston in the cylinder liner using a special holder for piston rings

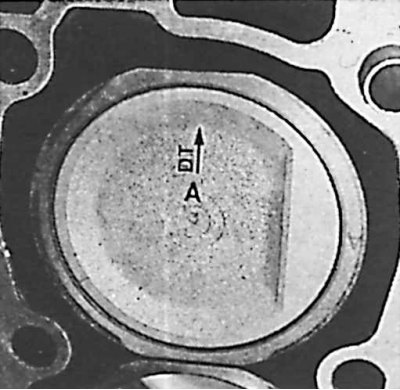

Install the piston on the tool so that "a drop" on its lateral surface was turned upwards. The arrow on the piston crown must also point upwards. Install the connecting rod accordingly.

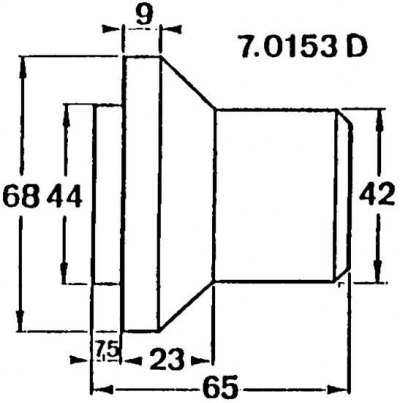

Dimensions of the crankshaft O-ring mandrel on the camshaft side

Assembly

1. Position the connecting rod on the heater in such a way that the connecting rod heads are heated and the connecting rod bases must be insulated with a heat-resistant plate or in another way; place a piece of solder on the connecting rod head as a temperature sensor.

2. Turn on the heater power, turn off the power when the solder begins to melt.

3. You need to do the following quickly:

- remove a drop of solder from the first connecting rod and prepare the connecting rod for installation;

- wait at least 10 seconds, and then raise the connecting rod and remove the entire assembly;

- remove the shank, and then perform the same steps for the remaining connecting rods;

- install rings on each piston (see fig. Typical piston ring placement);

- position the ring locks on the piston at a 120°angle.

4. The installation of the oil scraper ring locks should be as follows: the lock of each link should be on each side of the piston pin, 30-50 mm on both sides, the spring cut should be exactly on the axis.

5. O-ring settings (top) and sealing (second) must be such that their locks are offset by 120°relative to the spring and do not coincide. Install sealing rings with the inscription "TOP" up.

Attention! Do not interchange the O-rings, as the top and second O-rings have different profiles.

6. Pair the pistons with the cylinder liners. A special ring holder should be used. Installation signs must be observed. The arrow on the piston must point towards the camshaft drive, and the sign on the cylinder liner (in case of installation) – on the same side as before removal.

7. Install the cylinder liners with their O-rings in the cylinder block. If the sleeves are reinstalled, then their position relative to the cylinder block should be maintained. The pistons must be installed with the arrow pointing towards the camshaft drive. When installing the pistons in the cylinder, pre-compress the piston rings with a mandrel (see fig. Installation of the piston in the cylinder liner using a special holder for piston rings).

8. Install the connecting rod caps with liners and tighten them to the required torque.

9. Install the oil pump sprocket along with the key and chain on the crankshaft.

10. On the camshaft drive side, install the main bearing cap lubricated with Loctite.

11. Using a special mandrel 0.153D, install the sealing ring (see fig. Dimensions of the crankshaft O-ring mandrel on the camshaft side).

12. Put the chain on the oil pump, place a stand under the pump. Attach the pump.

13. Secure the oil pan together with its gasket.

14. Install the crankshaft in the timing setting position: the key must point towards the coolant pump and be installed horizontally.

15. Remove the setting element. Using, for example, a pin punch, hold it so that it protrudes from the surface of the cylinder block and install the cylinder head.

16. Install toothed belt and adjust its tension.