Engine

Cylinder head

The head is made of light alloy and has inserted seats and valve guides. The camshaft bearings are made in the material of the cylinder head.

| Rated Height: | |

| – engines 1580 cm3, 1761 cm3 and 1905 cm3 (with 8 valves) and 1998 cm3 (with 8 and 16 valves) | 158.93±0.05mm |

| – engine 1905 cm3 (16 valves) | 132.00±0.05mm |

| Minimum height after sanding: | |

| – engines 1580 cm3, 1761 cm3 and 1905 cm3 (with 8 valves) and 1998 cm3 (with 8 and 16 valves) | 158.73 mm |

| – engine 1905 cm3 (16 valves) | 131.80±0.05mm |

| Maximum flatness tolerance of the bottom surface of the head | 0.05 mm |

| Inner diameter of the camshaft bearings in the cylinder head: | |

| Engines 1580 and 1905 cm3: | |

– 1 | 27.000 - 27.033 mm |

– 2 | 27.500 - 27.533 mm |

– 3 | 28.000 - 28.033 mm |

– 4 | 28.500 - 28.533 mm |

– 5 | 36.000 - 36.039 mm |

Valves

The cylinder head has 8 (or 16) valves installed parallel to each other and at right angles to the lower surface of the head.

Valve sizes

| Valve disc diameter: | |

| - inlet valves: | |

| • engine 1580 cm3 | 41.6 mm |

| • engine 1761 cm3 | no data |

| • engine 1905 cm3 (with 8 valves) | 41.8 mm |

| • engine 1998 cm3 (with 8 valves) | 42.6 mm |

| • engines 1905 cm3 and 1998 cm3 (with 16 valves) | 34.7 mm |

| – exhaust valves: | |

| • engines 1580 cm3 and 1905 cm3 | 34.7 mm |

| • engine 1761 cm3 | no data |

| • engine 1998 cm3 (with 8 valves) | 34.5mm |

| • engines 1905 cm3 and 1998 cm3 (with 16 valves) | 29.7 mm |

| Valve stem diameter: | |

| - inlet valves: | |

| • engines 1580 cm3 and 1905 cm3 (with 8 valves) | 7.83 - 8.13 mm |

| • engine 1761 cm3 | no data |

| • engine 1998 cm3 (with 8 valves) | 7.83 - 7.98 mm |

| • engines 1905 cm3 and 1998 cm3 (with 16 valves) | 6.83 - 6.98 mm |

| – exhaust valves: | |

| • engines 1580 cm3 and 1905 cm3 | 7.83 - 8.13 mm |

| • engine 1761 cm3 | no data |

| • engine 1998 cm3 (with 8 valves) | 7.82 - 8.12 mm |

| • engines 1905 cm3 and 1998 cm3 (with 16 valves) | 6.83 - 6.98 mm |

| Valve length: | |

| - inlet valves: | |

| • engines 1580 cm3, 1905 cm3 and 1998 cm3 (with 8 valves) | 108.79±0.1mm |

| • engine 1761 cm3 | no data |

| • engines 1905 cm3 and 1998 cm3 (with 16 valves) | 104.48±0.1mm |

| – exhaust valves: | |

| • engines 1580 cm3, 1905 cm3 and 1998 cm3 (with 8 valves) | 108.37±0.1mm |

| • engine 1761 cm3 | no data |

| • engines 1905 cm3 and 1998 cm3 (with 16 valves) | 103.00±0.1mm |

| Valve contact angle | 90° |

| Edge width | 1.1mm |

| Valve clearance, except for engines with 16 valves (on a cold engine): | |

| - inlet valve | 0.20 mm |

| - Exhaust valve | 0.40 mm |

Attention! Exhaust valves do not grind.

Valve seats

The valve seats are inserted into the cylinder head and cannot be replaced.

Valve guides

The valve guides are plug-in, made of cast iron or brass.

| Outside diameter: | |

| - nominal | 13 0.08 or 13 0.05 mm |

| - repair size | 13.13±0.011 mm; 13.29±0.011 mm; 13.59±0.011mm |

Valve springs

One spring per valve is used. The intake and exhaust valves have the same springs.

Spring characteristics

| XU5 engine: | |

| - designation | green |

| - height: | |

| • at a load of 400 N | 42.5 mm |

| • at a load of 800 N | 31.0 mm |

| Engine XU9: | |

| - designation | black |

| - height: | |

| • at a load of 410 N | 40.5 mm |

| • at a load of 860 N | 30.0 mm |

| - designation | gray |

| - height: | |

| • at a load of 395 N | 41.5 mm |

| • at a load of 780 N | 31.0 mm |

Pushers

The tappets move directly in the material of the cylinder head. The adjustment of the working clearance of the valves is based on the installation of adjusting plates of the appropriate thickness between the valve stems and pushers.

Engines with 16 valves have hydraulic tappets for automatic valve clearance adjustment.

| Plate diameter | 13.5mm |

| Plate thickness: | |

| – every 0.025 mm | from 1.650 to 3.000 mm |

| – every 0.075 mm | from 3.025 to 3.550 mm |

| – every 0.025 mm | from 3.575 to 4.000 mm |

Cylinder head gasket

| Brand | Reinz or Curty |

| Gasket thickness: | |

| – nominal | 1.2mm |

| – for reground head | 1.4mm (designation by means of a notch and a hole with a diameter of 4 mm on the protrusion on one of the ends of the gasket) |

| Installation | flywheel protrusion |

Engine block

Engine block on models with a displacement of 1580 cm33, 1761 cm3 and 1905 cm3 (with 8 and 16 valves) It is made of light alloy and has plug-in wet cylinder liners. On models with a working volume of 1998 cm33 (with 8 and 16 valves), the cylinders are made directly in the body of the cylinder block.

The diameter of the bearing surface of the main bearings of the crankshaft: 63.708–63.727 mm.

Cylinder liners

Cylinder liners are clamp type, and tightness is ensured by an O-ring.

It is obligatory to select pairs of sleeves and pistons: the letter designation is applied on the bottoms of the pistons and on the upper edges of the sleeves.

| Engine cylinder bore diameter: | |

| – engines 1580 cm3, 1761 cm3 and 1905 cm3 (with 8 valves): | |

| • group A | from 83.000 to 83.010 mm |

| • group B | from 83.010 to 83.020 mm |

| • group C | from 83.020 to 83.030 mm |

| – engines 1998 cm3 (with 8 valves): | |

| • group A | from 86.000 to 83.010 mm |

| • group B | from 86.250 to 86.268 mm |

| • group C | from 86.600 to 86.618 mm |

| – engine 1905 cm3 (with 16 valves): | |

| • group A | from 83.000 to 83.010 mm |

| • group B | from 83.010 to 83.020 mm |

| • group C | from 83.020 to 83.030 mm |

| Protrusion of the liner relative to the cylinder block, except for 1998 cm3 (measured without o-ring) | 0.03 - 0.10 mm |

| Maximum difference between any two cases: | |

| – engines with 8 valves | 0.05 mm |

| – engines with 16 valves | 0.02mm |

Crank mechanism

Crankshaft

The crankshaft is made of cast iron and is supported by five main bearings.

| Longitudinal play of the crankshaft: | |

| – engines with 8 valves | from 0.07 to 0.32 mm |

| – engines with 16 valves | 0.07 to 0.27 mm |

| Diameter of main journals: | |

| – engines 1580 cm3, 1905 cm3 and 1998 cm3: | |

| • standard | from 59.981 to 60.000 mm |

| • repair | from 59.681 to 59.700 mm |

| – engine 1761 cm3 | no data |

| Crankpin diameter: | |

| – engines 1580 cm3, 1905 cm3 and 1998 cm3: | |

| • standard | from 49.984 to 50.000 mm |

| • repair | from 49.684 to 49.700 mm |

| – engine 1761 cm3 | no data |

| Operating clearance in main bearings: | |

| – engines 1580 cm3, 1761 cm3 and 1905 cm3 | from 0.025 to 0.050 mm |

| – engines 1998 cm3 | from 0.038 to 0.069 mm |

| Operating clearance in connecting rod bearings (all models) | from 0.025 to 0.050 mm |

Main bearing shells

| Thickness: | |

| – nominal | 1.842±0.003 mm |

| - repair size | 1.992±0.003 mm |

Connecting rod bearing shells

| Engine 1580 cm3: | |

| – nominal thickness | 1.812±0.01mm |

| - repair size | 1.962±0.01mm |

| Engine 1905 cm3: | |

| – nominal thickness | 1.833±0.003 mm |

| - repair size | 1.983±0.003 mm |

Thrust half rings (axial plain bearings)

| Thickness: | |

| – nominal | 2.30 or 2.35mm |

| – repair dimensions | 2.40, 2.45 and 2.50 mm |

Flywheel

The flywheel is bolted to the crankshaft with eight bolts.

Number of teeth of the ring gear: 136.

Connecting rods

The connecting rods are forged from steel. They have thin-walled liners made of aluminum-tin alloy.

| Distance between axles: | |

| – engine 1580 cm3 | 150.5 mm |

| – engine 1905 cm3 | 143.0 mm |

| Connecting rod bore diameter | 22±0.029mm |

| Connecting rod bore diameter: | |

| – engine 1580 cm3 | 48.655±0.016mm |

| – engine 1905 cm3 | 53.695±0.013 mm |

| Maximum difference in weight between connecting rods of the same engine: | |

| – engines 1580 cm3, 1761 cm3 and 1905 cm3 | 13 g |

| – engine 1998 cm3 | 7.0 g |

Pistons

Pistons are made of light alloy. The pin is fixed in the connecting rod with an interference fit, and in the piston - freely.

Installation: The arrow on the piston crown must point towards the camshaft drive.

Selection by pairs of liners and pistons: 3 groups of pistons: A, B and C correspond to 3 groups of cylinder liners, designated by the same letters (on the top edges).

Piston diameter

| Engines 1580 cm3, 1761 cm3 and 1905 cm3 (with 8 valves): | |

| – group A | 82.960±0.007mm |

| – group B | 82.970±0.007 mm |

| – group C | 82.980±0.007mm |

| Engine 1905 cm3 with 16 valves: | |

| – group A | from 82.963 to 82.977 mm |

| – group B | from 82.973 to 82.987 mm |

| – group C | from 82.983 to 82.997 mm |

Piston rings

| Castle gaps: | |

| – top sealing ring: | |

| • engine 1580 cm3 | 0.4 to 0.6 mm |

| • engine 1905 cm3 | 0.2 to 0.4 mm |

| • engines 1761 cm3 and 1998 cm3 | 0.3 to 0.5 mm |

| – second sealing ring: | |

| • engines 1580 cm3 and 1905 cm3 | 0.15 to 0.35 mm |

| • engines 1761 cm3 and 1998 cm3 | 0.3 to 0.5 mm |

| Oil scraper ring, all models | 0.3 to 0.5 mm |

Only UFLEX rings are now available as spare parts, which have replaced the previously used rings. Are established without a backlash on the lock. Their installation requires strong compression, as well as more attention and care so as not to break the rings.

Piston pins

The steel fingers are polished. Mount freely in the pistons and with an interference fit in the connecting rods. There are 3 groups of pins corresponding to piston groups marked with colored paint.

On 16-valve models, the piston pins have a sliding fit in the connecting rod and are secured with circlips.

Correspondence of the designation on the piston with the color of the sign on the finger

1 | blue |

2 | white |

3 | red |

Gas distribution system

The timing system consists of a camshaft mounted in the cylinder head, fixed in five bearings and driven by a toothed belt. The camshaft controls the operation of the valves by means of pushers equipped with gap adjustment plates.

The valve timing is determined with a theoretical gap of 1 mm.

| XU5 engine: | |

| - opening the intake valve | 6°30' advance |

| - closing the intake valve | 31° 18' |

| - opening the exhaust valve | 41° 18' |

| - closing the exhaust valve | 3° 30' |

| Engine XU9: | |

| - opening the intake valve | 3°lag |

| - closing the intake valve | 46° |

| - opening the exhaust valve | 40° 8' |

| - closing the exhaust valve | 2° 2' |

Camshaft

The camshaft is mounted in the cylinder head and mounted in five bearings made directly in the material of the cylinder head and is driven by a toothed belt.

| Camshaft bearing diameter (engines 1580 cm3 and 1905 cm3): | |

| – 1 | 26.980 - 26.959 mm |

| – 2 | 27.480 - 27.459 mm |

| – 3 | 27.980 - 27.959 mm |

| – 4 | 28.480 - 28.459 mm |

| – 5 | 35.975 - 35.950 mm |

Toothed belt

Brand: Uniroyal Powergrip 58113 x 17.

Belt tension is provided by a roller tensioner.

Lubrication system

Pressure lubrication is provided by an oil pump driven by a chain from the crankshaft.

The oil pressure sensor is adjusted to 0.08 MPa.

Since April 1987 the oil pump has been 5 mm higher. Removed the spacer located between the pump and the cylinder block, as well as the intermediate sleeve, mounted on the cylinder block.

A new pump can be installed in place of the old one, provided that the intermediate element is removed and washers are placed under the pump mounting bolts.

The length of the drive chain remained unchanged.

Oil pump

The gear oil pump body is made of light alloy.

| Oil pressure at 90°C: | |

| – XU5 engine | 0.35 MPa at 4000 rpm |

| – XU7 engine | 0.53 MPa at 4000 rpm |

| – XU9 engine | 0.41 MPa at 4000 rpm |

| – XU10 engine | 0.52 MPa at 4000 rpm |

Oil filter

The oil filter with replaceable element has an attached bypass valve.

Make and type: Purflux LS 468 A.

Engine oil

| Quantity: | |

| - XU engine (8 valves) without a filter | 4.5 dm3 |

| - XU engine (8 valves) with filter | 5.0 dm3 |

| - XU engine (16 valves) without a filter | 5.0 dm3 |

| - XU engine (16 valves) with filter | 5.3 dm3 |

| Recommended Type | SAE 10W/40 or 15W/50, API SF, CCMC G3, Esso Super Oil 10W/40 or Shell Puissance 5 SAE 10W/40 |

Cooling system

The engine is cooled under pressure (0.1 MPa) a mixture of water and a special antifreeze liquid. The cooling system consists of a radiator, a coolant pump, an expansion tank and a fan with an electric motor.

Coolant pump

The centrifugal coolant pump is installed in the engine block and is driven by a toothed belt.

Radiator

The radiator has a horizontal flow aluminum core.

Brand: Chausson or Valeo.

Thermostat

| Opening start temperature: | |

| – engines 1580 cm3: | |

| • all engines except B2A (XU52C) and BDY (XU5M) | 88° C |

| • B2A engines (XU52C) and BDY (XU5M) | 82° C |

| – engines 1761 cm3 | 88° C |

| – engines 1905 cm3: | |

| • all engines except D2H (XU92C), D5A (XU92C) and D6D (XU9J2) | 88° C |

| • D2H engines (XU92C), D5A (XU92C) and D6D (XU9J2) | 82° C |

| – engines 1998 cm3: | |

| • RFX motors (XU10J2C) and RFY (XU10J4) | 89° C |

| • RGZ engine (XU10J4) | 88° C |

| Full opening temperature: | |

| – engines 1580 cm3: | |

| • all engines except B2A (XU52C), B3B (XU51C) and BDY (XU5M) | 100 ° C |

| • B2A engine (XU52C) | 93° C |

| • B3B engine (XU51C) | 102° C |

| • BDY engine (XU5M) | 94° C |

| – engines 1761 cm3 | 100° C |

| – engines 1905 cm3: | |

| • all engines except D2H (XU92C), D5A (XU92C) and D6D (XU9J2) | 100° C |

| • D2H engines (XU92C) and D5A (XU92C) | 93° C |

| • D6D engine (XU9J2) | 94° C |

| – engines 1998 cm3: | |

| • RFX motors (XU10J2C) and RFY (XU10J4) | 101° C |

| • RGZ engine (XU10J4) | 100° C |

Fan

The fan is driven by an electric motor and has two speeds.

Temperature | 1 speed | 2 speed |

| Inclusions | 90° C | 94° C |

| Shutdown | 86° C | 90° C |

Temperature sensor

Switching temperature of control light: 110°C.

Coolant

Quantity | 6.6 dm3 |

| Recommended Type | a mixture of water and antifreeze in a ratio of 1:1 (up to -17°С) |

| Intervals for changing the coolant and flushing the cooling circuit | every 2 years |

Supply system

Fuel tank

The fuel tank is made of artificial material and is installed under the floor in front of the rear axle.

Volume: 70 dm3 (petrol 98 or unleaded petrol Eurosuper 95).

Fuel pump

The mechanical, diaphragm fuel pump is driven by a camshaft eccentric.

Air filter

| View | dry filter |

| Brand and type | Mann Microtop C 33 156 |

Carburetor

The two-chamber carburetor has an automatic starter, pneumatic enrichment at maximum power and a second chamber lock when the engine is cold.

Brand and type:

- XU5 engine: Solex 34/34 Z1 designation 446/460;

- XU9 engine: Solex 34/34 Z1 designation 447/462.

Carburetor type | Solex 34/34 Z1 446/460 | Solex 34/34 Z1 447/462 | ||

1 camera | 2 camera | 1 camera | 2 camera | |

| diffuser diameter (mm) | 25 | 27 | 26 | 27 |

| Main fuel jet | 1,150 | 1,275 | 1,200 | 1,225 |

| Main air jet | 1,450 | 1,600 | 1,500 | 1,600 |

| Main air jet | 18 | ZC | BZ | ZC |

| Fuel jet idling | 0,46 | 0,90 | 0,45 | 0,90 |

| Idle air jet | 1,45 | 1,45 | 1,45 | 1,45 |

| Calibrated enrichment jet | 0,5 | 0,5 | ||

| Needle seat diameter | 1,8 | 1,8 | ||

| accelerating pump atomizer | 0,35 | 0,35 | 0,40 | 0,40 |

| Opening 2 chambers | – | 9° | – | 9° |

| Fuel level in float chamber (mm) | 33,5 | 33,5 | ||

| Turnovers "quick" idle move (rpm) | 2450 – 2600 | 2450 – 2600 | ||

| idle speed (rpm) | 750 ± 100 | 750 ± 100 | ||

| CO content (%) | 0,8 – 1,5 | 0,8 – 1,5 | ||

| Minimum CO content2 (%) | 10 | 10 | ||

Single point fuel injection system

| System type: | |

| – XU5 engine (BDZ and BDY) | Magneti Marelli G5 single point |

| – XU5 engine (BDY) | MagnetiMarelli G6 single point |

| – XU9 engine (DDZ) | Solex Fenix IB single point |

Fuel pump

Electric type, external (early models) or internal (later models).

| Pump feed pressure: | |

| – injection system Fenix IB, MM G5 and MM G6 | 0.7 - 0.8 bar |

| – Bosch MA3 injection system. 0 | 1.0±0.1 bar |

| Pump performance: | |

| – Fenix IB and Bosch MA3 injection system | 0 - 370 cm3 in 15 seconds |

| – injection system MM G5 and G6 | 360 cm3 in 15 seconds |

Multipoint fuel injection systems

| System type: | |

| – XU5 engine (BFZ), XU7 (LFZ), XU10 (RFX), XU10 (R6D) | Magnett Marelli 8P multipoint |

| – XU5 engine (BFZ) | Sagern-Lucas 4GJ multipoint |

| – XU7 engine (LFZ) | Bosch Motronic MP5. l multipoint |

| – XU9 engine (D6A and D6D) | Bosch L3. l-Jetronic multipoint |

| – XU9 engine (D6D) | Bosch Motronic MP3. l multipoint |

| – XU9 engine (DKZ and DFZ) | Bosch LU2-JETRONIC multipoint |

| – XU9 engine (DKZ and DFV), XU9 (DFW with 16 valves) | Bosch Motronic MI. 3 multipoint |

| – XU9 engine (D6C with 16 valves) | Bosch Motronic ML4. l multipoint |

| – XU10 engine (RFY with 16 valves), XUIO (RFT) | Bosch Motronic MP3. 2 multipoint |

Fuel pump

Electric type, external (early models) or internal (later models).

| Pressure generated by fuel pump at specified idle speed: | |

| – Bosch L3 system. l | 2.5 bar |

| – other Bosch systems | 3.0±0.2 bar |

| – Magneti Marlli system | 2.5±0.2 bar |

| Idle speed: | |

| – Boscn L3 system | 925±25 rpm |

| – other systems | 850±50 rpm |

Recommended fuel

| Minimum octane: | |

| – TU3 engines (KIA), TU3A (KIG), XU92C (D2D), XU9J2 (DGA),XU9J4 (D6C), XU52C (B2A) | 97 |

| - other models | 95 |

Ignition system

| Models with L3 carburetor. l-Jetronlc and LU2-JETRONIC | non-contact ignition system |

| Other models except XU10J4 with 16 valves | composite ignition system controlled by the ECU |

| Models XU10J4 (with 16 valves) | direct ignition system controlled by the ECU |

The transistorized non-contact ignition system has a distributor with a built-in Hall effect sensor, as well as centrifugal and vacuum regulators.

Distributor

| Brand | Bosch or Ducellier |

| Designation of characteristics: | |

| – XU5 engine | C 005 and D 020 |

| – XU9 engine | C 053 and D 040 |

| Starting ignition timing: | |

| – XU5 engines (B2A) and XU9 (D2H) with carburetor | 10°before TDC at 750 rpm |

| – Models with fuel injection system: | |

| • L3. l-Jetronic | 5°before TDC at 900 rpm |

| • LU2- Jetronic | 10°before TDC at 850 rpm |

| - all other models | controlled by the ECU (not regulated) |

| Ignition order | 1–3–4–2 (No. 1 Camshaft Drive Side) |

Attention! If low octane fuel is used, the ignition timing must be reduced by 3°on the following engines: XU92C (D2D), XU9J2 (D6A), XU9J4 (D6C) and XU52C (B2A).

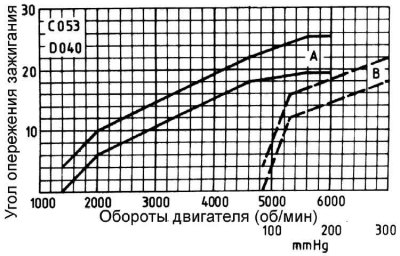

Ignition advance characteristics (XU9 engine)

A - centrifugal regulator

B - vacuum regulator

During the test at the stand (ignition distributor removed) values must be reduced by half. When checking the distributor installed in the car, it is necessary to add the value of the initial ignition timing.

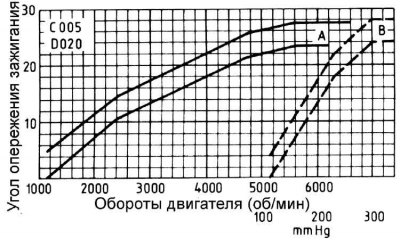

Ignition advance characteristics (XU5 engine)

A - centrifugal regulator

B - vacuum regulator

During the test at the stand (ignition distributor removed) values must be reduced by half. When checking the distributor installed in the car, it is necessary to add the value of the initial ignition timing.

Ignition coil

| Brand | Bosch or Ducellier |

| Winding resistance: | |

| – primary | 0.7 ohm |

| - secondary | 6.6 kOhm |

Spark plug

Spark plugs have a cone seal (do not have gaskets).

Make and type: Champion C7YCX or Eyquem FC 62 LS.

Tightening torques

XU5, XU7 and XU9 engines

| Cylinder head: | |

| - Stage 1 | tightening torque 60 Nm |

| – stage 2 | unscrewing and then tightening with a torque of 20 Nm |

| – Stage 3: | |

| • Torx bolts | tightening at an angle of 300° |

| • hex bolts | tightening at an angle of 120° |

| Timing belt guard | 8 Nm |

| Timing Belt Tensioner Pulley Bolt | 20 Nm |

| Oil pump | 13 Nm |

| Connecting rod bearing cap: | |

| - Stage 1 | tightening torque 40 Nm |

| – stage 2 | unscrewing and then tightening with a torque of 20 Nm |

| – Stage 3 | tightening at an angle of 70° |

| Front seal | 16 Nm |

| Main bearing caps | 52.5 Nm |

| Side bolts of caps of main bearings | 22 Nm |

| Crankshaft pulley: | 120 Nm |

| Flywheel | 50 Nm |

| Camshaft pulley | 80 Nm |

| Camshaft bearings | 15 Nm |

| oil pan | 20 Nm |

| cylinder head cover | 10 Nm |

| Spark plug | 17.5 Nm |

XU10 engines

| cylinder head cover | 10 Nm |

| Timing belt guard | 8 Nm |

| crankshaft pulley | 110 Nm |

| Toothed belt tensioner | 20 Nm |

| Cylinder head bolts: | |

| - Stage 1 | tightening torque 35 Nm |

| – stage 2 | tightening torque 70 Nm |

| – Stage 3 | tightening at an angle of 160° |

| oil pan | 16 Nm |

| Oil pump | 13 Nm |

| Connecting rod bearing cap: | |

| - Stage 1 | tightening torque 40 Nm |

| – stage 2 | unscrewing and then tightening with a torque of 20 Nm |

| – Stage 3 | tightening at an angle of 70° |