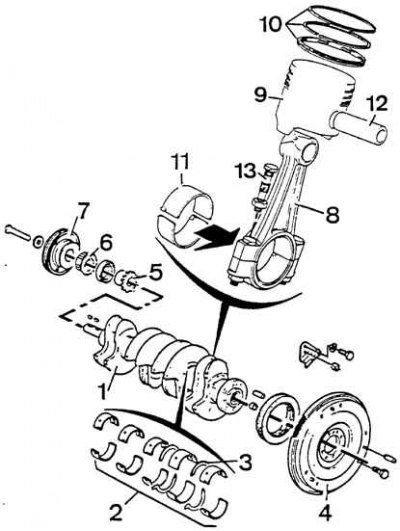

Crank mechanism

1 - crankshaft, 2 - main bearing shells, 3 - thrust half rings of the crankshaft, 4 - flywheel, 5 - oil pump drive sprocket, 6 - timing gear pulley, 7 - wedge pulley, 8 - connecting rod, 9 - piston, 10 - piston rings, 11 - connecting rod bearings, 12 - piston pin, 13 - connecting rod cap bolt

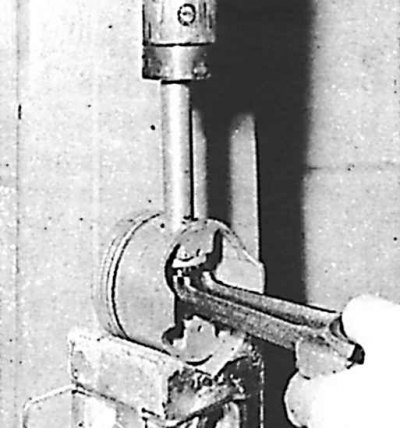

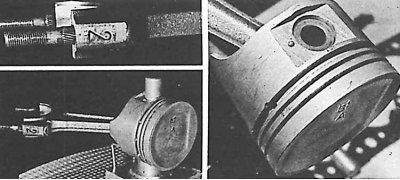

Removing the piston pin on a press on engines with 8 valves

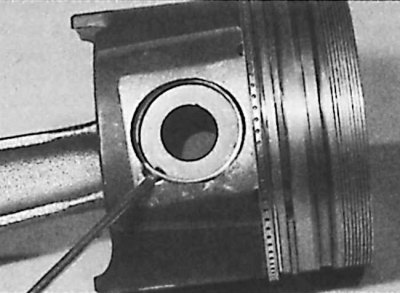

Removing the Piston Pin Retaining Ring on 16 Valve Engines

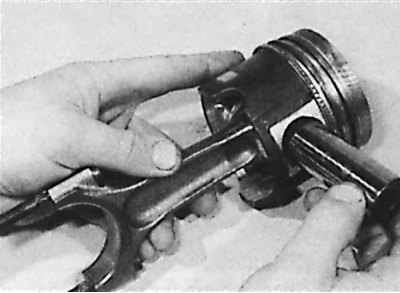

Piston pin removal on 16 valve engines

Piston and piston ring wear can usually be detected by signs of increased oil consumption and low compression, sometimes associated with cylinder wear.

Another sign of piston wear is piston knock, similar to noise from the crankshaft, which must be distinguished from bearing knock. It can be heard clearly at low engine speeds with no load (e.g. at idle), it is heard much less with increasing engine speed. Piston wear usually occurs at the skirt or bottom of the piston.

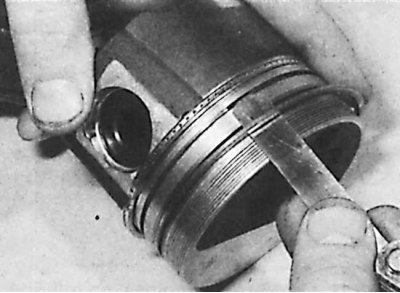

1. Remove the top o-ring, middle o-ring and oil scraper ring in turn. To remove the rings, insert thin steel plates under the ring (can probes) in several places evenly along the perimeter of the piston and along the plates, slide the piston ring off the piston.

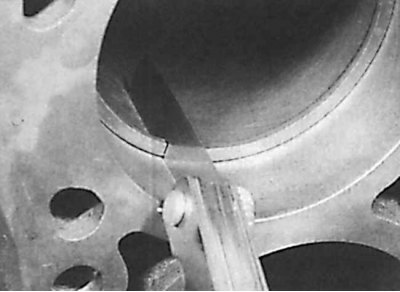

2. Check the gap in the ring lock. To do this, sequentially insert all the rings from the upper side into the working cylinder sleeve. With the piston upside down, push the ring down into the cylinder to a depth of 15 mm and measure the gap in the ring lock with a feeler gauge. The gaps in the lock of the ring are not adjustable, and if the gap increases beyond the allowable one, the ring must be replaced.

3. Disassemble the connecting rod-piston units by removing the piston pins with a press (see fig. Removing the piston pin on a press on engines with 8 valves and fig. Piston pin removal on 16 valve engines).

4. To remove and install the piston pins, use special equipment, namely, a guide and a bracket. Install a guide on the pin before pressing it in. However, the pin must not be attached to the shank before being pressed in, a gap of approx. 0.1 mm must be left.

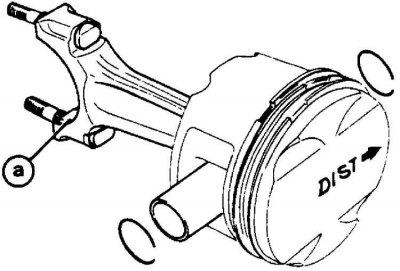

5. On engines with 16 valves, when installing the piston and connecting rod, ensure their correct relative position (a - mark on the base of the connecting rod).