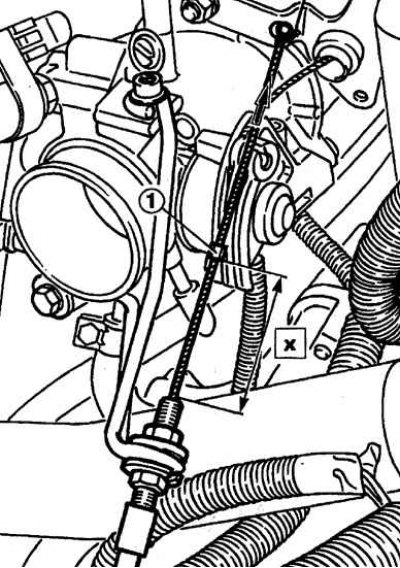

Distance measurement (X) between the protrusion on the downshift cable and the threaded end of the cable sheath

1 - cable for forced downshifting

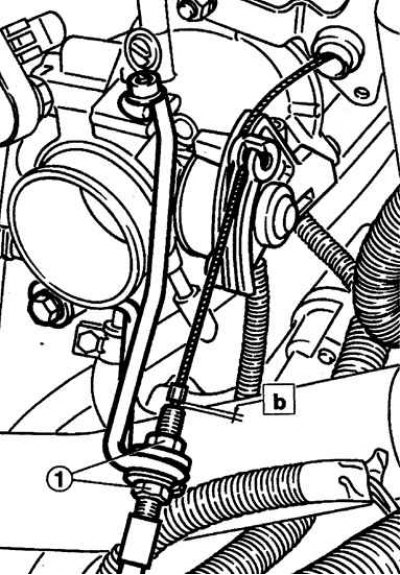

Gap measurement (b) between the protrusion on the cable for forced downshifting and the threaded end of the cable sheath and the nut for adjusting the gap

1 - nut for adjusting the gap

The downshift cable adjustment should be done with the engine warm.

Adjustment

1. Check and, if necessary, adjust the idle speed.

2. Stop the engine and check the adjustment of the accelerator cable. Disconnect the positive downshift cable from the lever on the carburetor or throttle body and recheck the throttle cable adjustment.

3. Pull the positive downshift cable out of the sheath and measure the distance between the lug on the cable and the threaded end of the cable sheath, which should be 39.0 mm. If the measured value is not equal to 39.0 mm, unscrew the two lock nuts for fixing the cable sheath and, moving the nuts along the cable sheath, set the required distance (see fig. Distance measurement (X) between the protrusion on the downshift cable and the threaded end of the cable sheath).

4. Reconnect the positive downshift cable to the carburetor or lever on the throttle body, and check the gap between the tab on the cable and the threaded end of the cable sheath, which should be 0.5 mm. If the measured value is not equal to 0.5 mm, unscrew the two lock nuts fixing the cable sheath and moving the nuts along the cable sheath set the required distance (see fig. Gap measurement (b) between the protrusion on the cable for forced downshifting and the threaded end of the cable sheath and the nut for adjusting the gap).