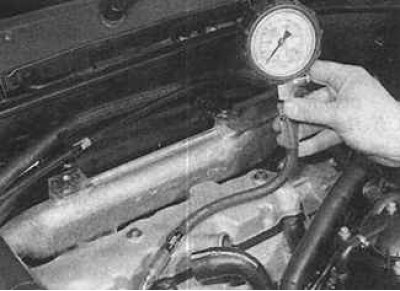

To measure the compression pressure, a compression gauge for diesel engines with a maximum reading of at least 30 bar is required.

1. Fully charge the battery. Adjust valve clearances. Warm up the engine to operating temperature. Unscrew all nozzles.

2. Disconnect the glow plug power and the fuel solenoid valve connector. On 2.1 liter engines, remove the fuel injection relay located in the ECU.

3. Screw the adapter of the compression tester into the injector socket. Turn the crankshaft with the starter several times. Record the maximum compression pressure.

4. Repeat measurements on the remaining three cylinders.

5. The compression pressure in all cylinders should not differ by more than two units. Note that the amount of compression should increase rapidly on a healthy engine; low compression pressure on the first revolution of the crankshaft, followed by a gradual increase in pressure on subsequent revolutions of the crankshaft, indicates worn piston rings. A low pressure value at the first revolution of the crankshaft, which increases slightly thereafter, indicates a loose valve seat, a blown cylinder head gasket, or a crack in the cylinder head. Worn valve stem ends can also result in low compression pressure.

6. If the pressure in one cylinder is low, then carry out the following test. Pour some engine oil through the spark plug hole into the cylinder and check the compression pressure. If adding oil to the cylinder increases the compression pressure, this indicates that the cylinder or piston rings are worn.

7. Low pressure in two adjacent cylinders indicates a burnt gasket between the cylinders.

8. If the pressure in one cylinder is less than 20% than in the others, and the engine runs erratically at idle, this indicates a worn camshaft lobe.

9. If the compression pressure is too high, this indicates that the combustion chamber is covered with a thick layer of soot.