Removing

1.9 liter engines

1. Remove the cylinder head cover.

2. Remove the pulley from the camshaft.

3. Remove the brake vacuum pump.

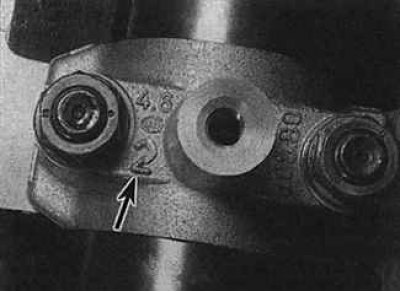

4. The camshaft bearing caps are numbered on the flywheel side (arrow). If the caps are not numbered, mark them on the flywheel side.

5. Gradually unscrew the nuts and remove the camshaft bearing caps.

6. Remove the camshaft from the cylinder head. Remove the O-ring from the camshaft on the toothed belt side. At installation use a new sealing ring.

7. Using a rubber suction cup, remove the pushers and place them in a suitable container so that they fall into place when installed. If necessary, remove the shim from the top of the valve stem and store it with an appropriate tappet.

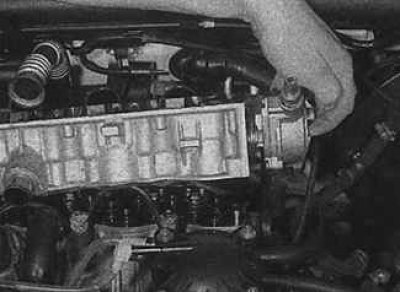

Engines 2.1 liters

8. Remove the cylinder head cover.

9. Remove the camshaft pulley.

10. Remove the brake vacuum pump. Remove the oil supply pipe to the pump from the end of the camshaft.

11. Remove the fuel supply and return lines from the fuel injectors.

12. Remove the oil return hose from the front of the camshaft bearing housing.

13. Gradually and sequentially loosen and unscrew the 16 bolts securing the camshaft bearing housing.

14. Lift up the camshaft bearing housing together with the camshaft.

15. Remove the O-ring from the end of the camshaft bearing housing.

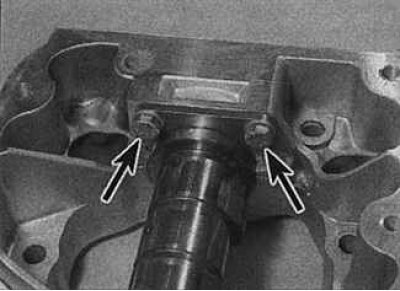

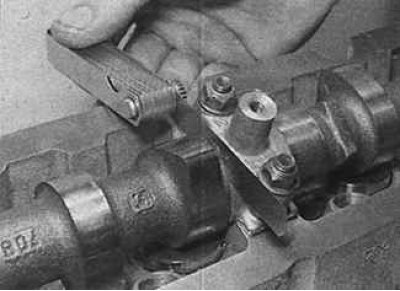

16. Unscrew the two fixing screws (indicated by arrows) camshaft thrust plate, remove the plate and remove the camshaft from the camshaft bearing housing.

17. Prepare 12 plastic containers and number them 1 to 8 for the intake valves and 1 to 4 for the exhaust valves.

18. Unscrew the two fixing screws (indicated by arrows) camshaft thrust plate, remove the plate and remove the camshaft from the camshaft bearing housing.

|  |

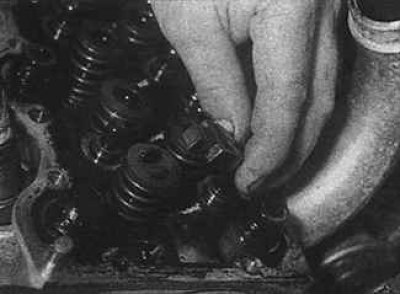

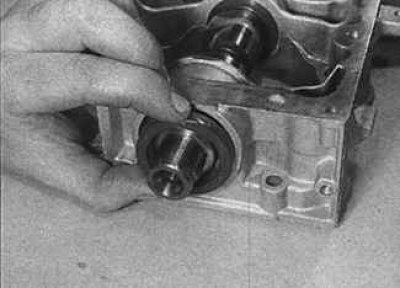

19. Remove the valve levers (photo on the left), gaskets (photo on the right) and hydraulic pushers and place them in appropriate containers.

20. Remove the oil filter from the cylinder head.

Examination

Check camshaft bearing surfaces and cam contours for signs of wear. If there is any wear, the camshaft must be replaced. Check the condition of the running surfaces of the bearings in the camshaft bearing housing and the camshaft journals. If the bearing surfaces are worn out, the camshaft bearing housing must be replaced.

Installation

1.9 liter engines

1. If removed, install the shim on the valve stem. Under no circumstances should the gaskets be interchanged, as valve clearances will be broken.

2. Lubricate with a thin layer of oil and install pushers.

3. Lubricate the cam contours and camshaft bearing journals with clean engine oil.

4. Temporarily install the crankshaft pulley and align the mounting holes in the pulley and the cylinder head, the projections of the 4th cylinder should be directed upwards. Remove the pulley and install the camshaft in the cylinder head with the lugs on cylinder #4 pointing up. Check that the crankshaft is locked by the dowel pin.

5. Install the center bearing cover according to the previously marked markings and screw on the nuts two or three turns.

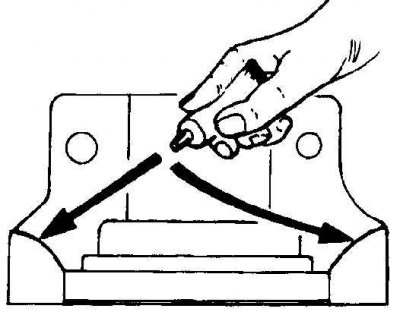

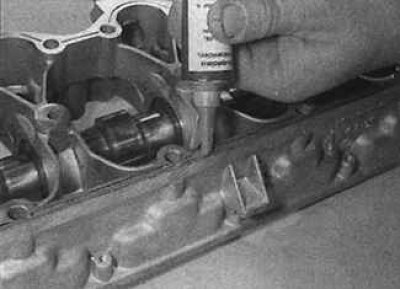

6. Apply sealant to the camshaft bearing cap (sealant application areas are shown by arrows), install them in the required position and tighten the nuts two or three turns.

7. Gradually and sequentially tighten all nuts to the required torque.

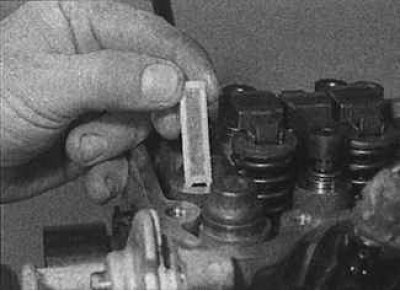

8. Using a feeler gauge, check the camshaft end play. To check for free play, move the camshaft to one end of the cylinder head and insert a feeler gauge blade between the thrust surfaces of one of the camshaft lugs and the bearing cap.

9. If a previously removed camshaft is installed, valve clearances do not need to be adjusted. If not, check and adjust valve clearances. Since the toothed belt has not yet been installed, it is necessary to turn the crankshaft a quarter of a turn in either direction so that the pistons are in the cylinders at half the piston stroke, i.e. none of the pistons were at top dead center. This will prevent the pistons and valves from hitting as the camshaft rotates.

10. Lubricate the lips of the new O-ring with clean engine oil and install it on the camshaft with the lips facing inward. Press it into the seat flush with the camshaft bearing cap.

11. If the crankshaft was turned, it is necessary to turn it back the same amount so that the pistons of the first and fourth cylinders are at top dead center. In no case do not turn the crankshaft a large amount, because. the pistons of the second and third cylinders can move to the top dead center position and they will collide with the valves.

12. Insert the locating rod to fix the flywheel.

13. Install the camshaft pulley.

14. Install the cylinder head cover.

Engines 2.1 liters

15. Lightly coat the camshaft and bearing journals in the camshaft bearing housing with a thin layer of oil, and insert the bearing housing into the camshaft. Install thrust plate and secure with two bolts.

16. Lubricate the hydraulic tappets and place them in their respective holes.

|  |

17. Lubricate the gaskets and levers and place them over the respective valves (the installation of gaskets is shown in the photo on the left, the installation of the valve lever is in the photo on the right).

18. Insert a new oil filter into the hole in the cylinder head.

19. Lubricate the sealing lips of the new camshaft seal and install on the camshaft.

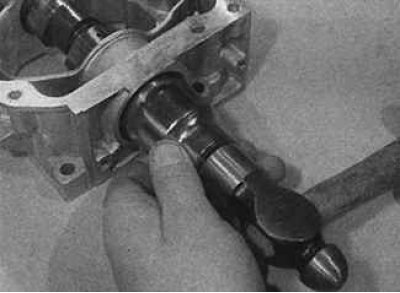

20. Press the O-ring into the seat using a hammer and drift.

21. Apply sealant between the groove and the outer edge of the camshaft bearing housing plane.

22. Install the camshaft bearing housing with camshaft onto the cylinder head. At the same time, do not move the valve levers.

23. Install the mounting bolts and screw them in a spiral sequence, from the center outward, gradually tightening the bolts to the required torque.

24. Reconnect the oil return hose to the front of the camshaft bearing housing.

25. Connect the fuel supply and return lines to the fuel injectors.

26. Make sure the oil supply pipe is in place and install the brake vacuum pump.

27. Install the camshaft pulley.

28. Install the cylinder head cover.